Honeycomb structure

A honeycomb structure and honeycomb technology, applied in the direction of gas treatment, dispersed particle filtration, metal/metal oxide/metal hydroxide catalyst, etc., can solve the problems of driving performance impact, increase pressure loss, etc., and achieve anti-purification performance The effect of reducing and suppressing the rise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Hereinafter, embodiments of the honeycomb structure of the present invention will be described in detail with reference to the drawings. In addition, the honeycomb structure of the present invention is not particularly limited to the following embodiments, and various design changes, corrections, improvements, etc. can be added as long as they do not deviate from the gist of the present invention.

[0029] [1]Honeycomb structure

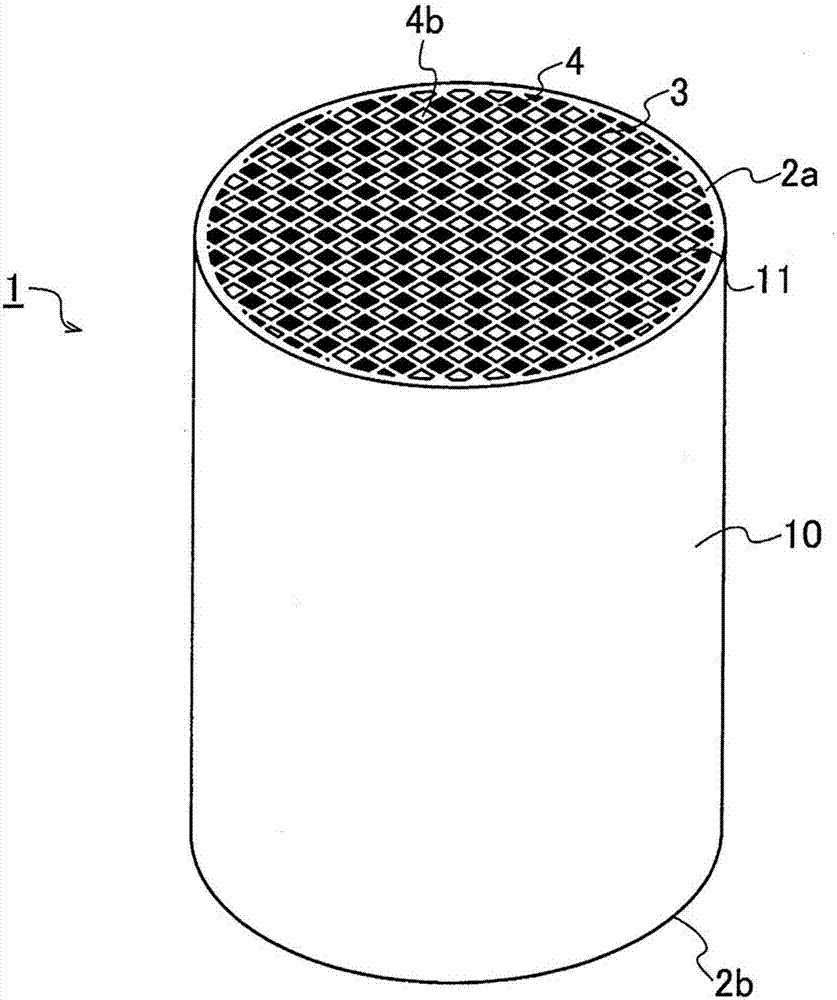

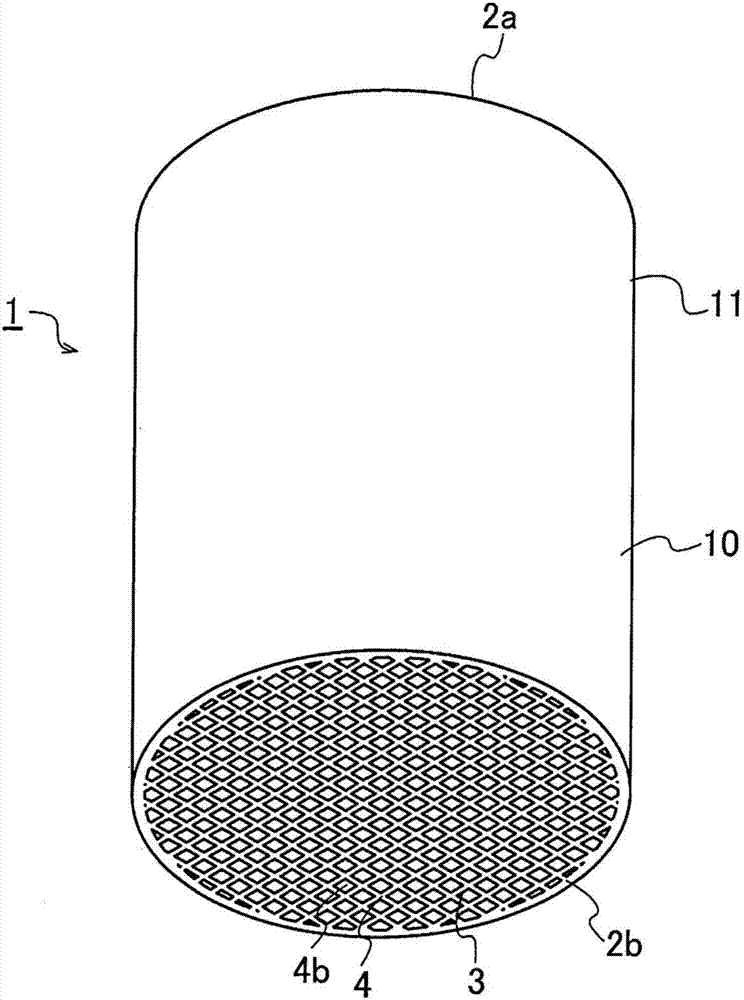

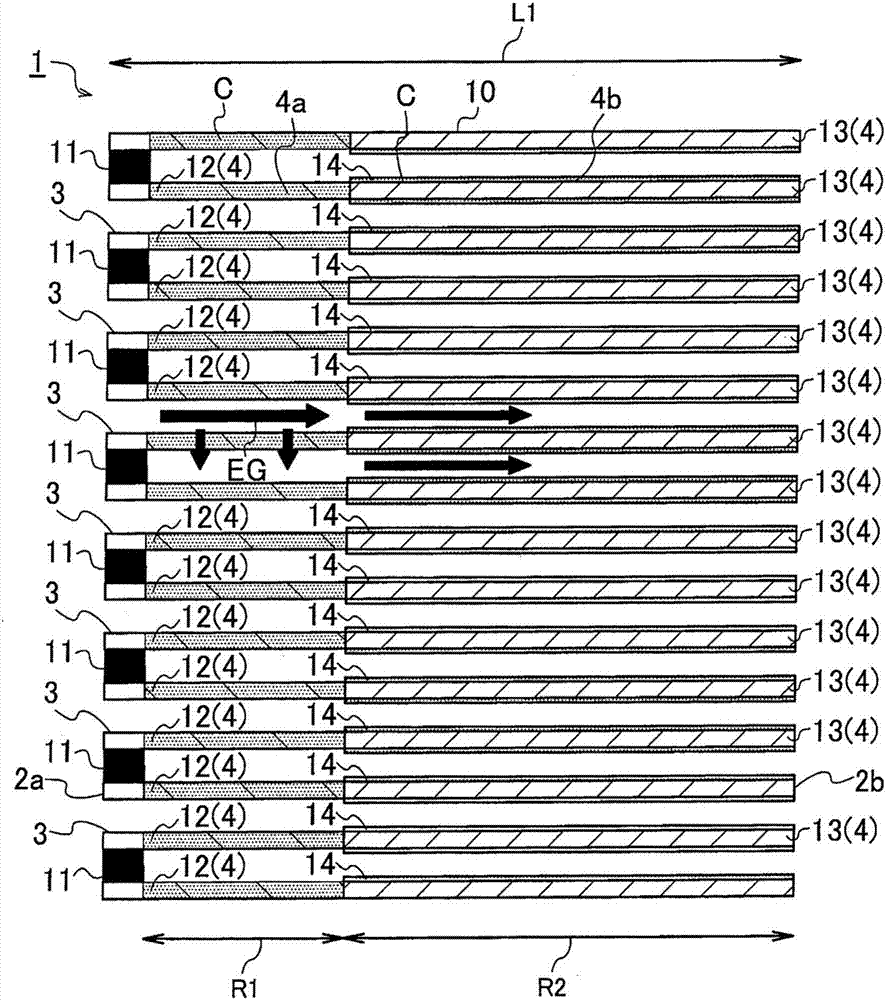

[0030] mainly as figure 1 as well as figure 2 As shown, the honeycomb structure 1 of the present embodiment is mainly composed of a substantially columnar honeycomb base material 10 having a porous lattice shape made of a ceramic material to define a plurality of cells 3 . The partition wall 4, the plurality of compartments 3 extend from one end face 2a to the other end face 2b of the honeycomb base material 10; The compartment 3 of the end face 2a is sealed.

[0031] For the one-side plugging portion 11 of the honeycomb structure 1 of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com