Exhaust gas purification system for internal combustion engine

A technology for exhaust purification and internal combustion engines, applied to internal combustion piston engines, exhaust devices, exhaust treatment, etc., can solve the problems of reduced vehicle mountability, reduced degree of freedom of exhaust purification systems, and increased manufacturing costs, achieving improved freedom degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

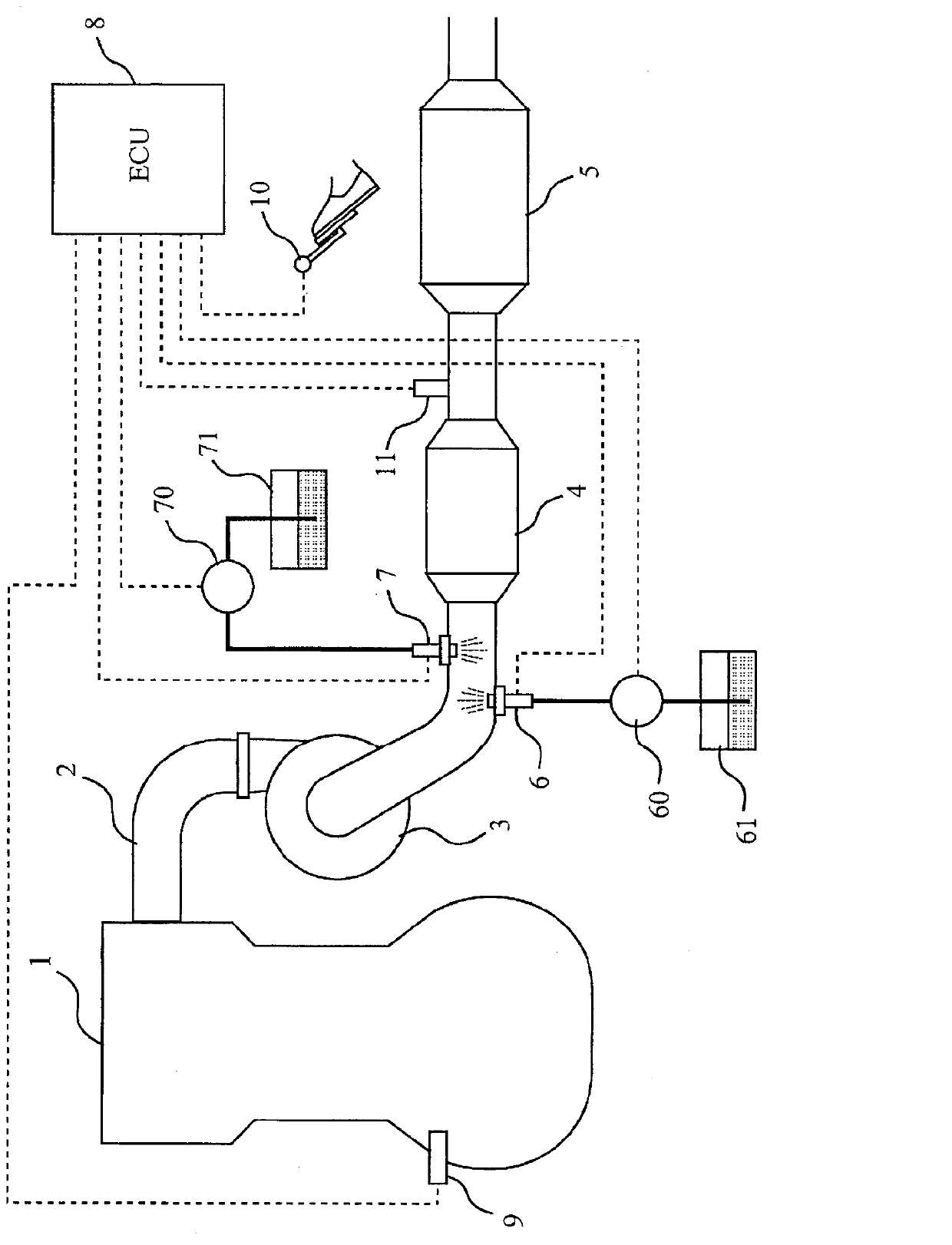

[0040] First, based on Figure 1 to Figure 4 A first embodiment of the present invention will be described. figure 1 It is a diagram showing a schematic configuration of an exhaust system of an internal combustion engine to which the present invention is applied. figure 1 The internal combustion engine shown is a compression-ignition internal combustion engine (diesel engine), but it could also be a spark-ignition internal combustion engine (gasoline engine).

[0041] figure 1 In the internal combustion engine 1, an exhaust passage 2 is connected. The exhaust passage 2 is a passage through which gas (exhaust gas) flowing out of the cylinders of the internal combustion engine 1 flows. A turbine 3 of a centrifugal supercharger (turbocharger) is arranged in the middle of the exhaust passage 2 . An exhaust purification device 4 is arranged in the exhaust passage 2 downstream of the turbine 3 .

[0042] The exhaust purification device 4 accommodates a selective reduction catalys...

Embodiment 2

[0083] Second, based on Figure 5 A second embodiment of the present invention will be described. Here, configurations different from those of the first embodiment described above will be described, and descriptions of the same configurations will be omitted.

[0084] The difference between this embodiment and the first embodiment described above is that a burner 12 is added to the exhaust passage 2 between the turbine 3 and the exhaust purification device 4 . The burner 12 is a device for combusting secondary air supplied from the air pump 120 and fuel supplied from the first pump 60 .

[0085] The combustion chamber 12 is provided with an unillustrated spark plug, and the secondary air and fuel are combusted by the operation of the spark plug. The gas (combustion gas) combusted by the burner 12 is introduced into the exhaust passage 2 through the discharge pipe 121 . In addition, in Figure 5 In the example shown, the burner 12 and the fuel addition valve 6 share the fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com