Metal nanoparticle preparing method

A metal nanoparticle, metal nanoparticle technology, applied in nanotechnology, nanotechnology, metal processing equipment and other directions, can solve the problems of difficulty in collection, low productivity, and high equipment cost, and achieve a wide range of raw material resources, strong selectivity, and preparation. simple craftsmanship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

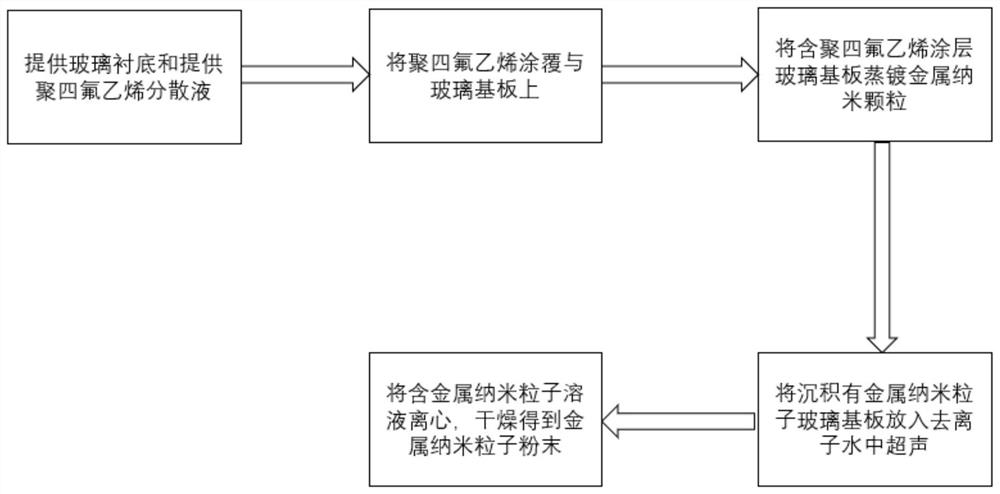

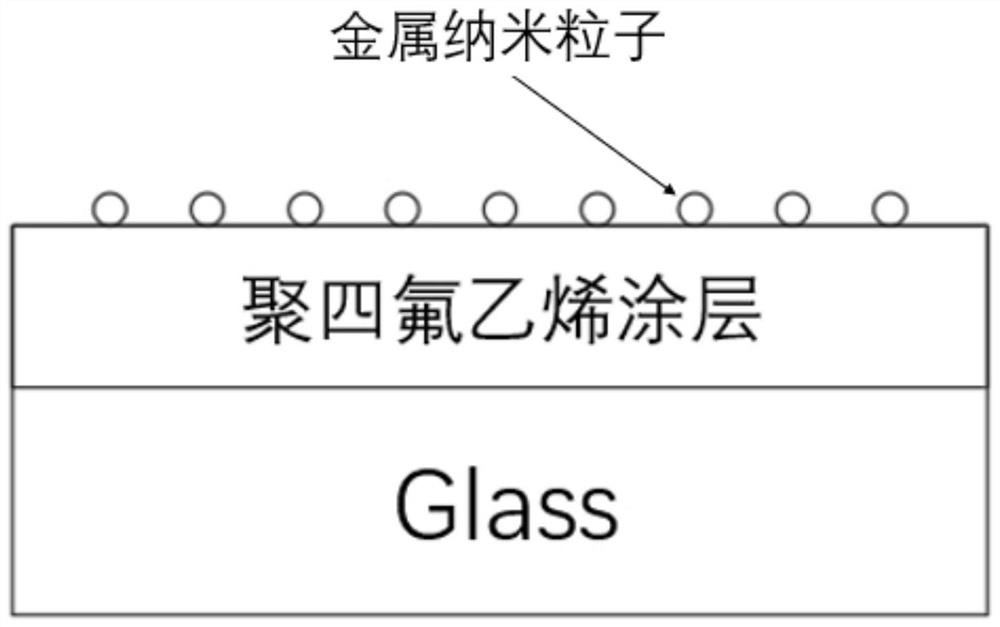

[0031] In this example, see figure 1 and figure 2 , a method for preparing metal nanoparticles, comprising the steps of:

[0032] (1) Use a glass substrate as the substrate; the size of the glass substrate is 3.1cm×2.6cm, and the thickness is 0.2cm; the substrate is cleaned with a cleaning agent and then dried;

[0033] (2) Using polytetrafluoroethylene (PTFE) dispersion liquid, using deionized water as a solvent for the polytetrafluoroethylene dispersion liquid, preparing the dispersion liquid with a mass fraction of 60%, then placing the prepared solution on a magnetic stirrer, and stirring for 3 hours;

[0034] (3) After coating the polytetrafluoroethylene dispersion in the step (2) on the surface of the glass substrate in the step (1), set the spin coating speed as 3000r / min, and the spin coating time is 60s; then Dry at 100°C for 5 minutes under a baking lamp to form a polytetrafluoroethylene coating with a thickness of 0.5mm;

[0035] (4) Evaporate metal gold on the ...

Embodiment 2

[0041] This embodiment is basically the same as Embodiment 1, especially in that:

[0042] In the above embodiment, a method for preparing metal nanoparticles comprises the following steps:

[0043] (1) Use a glass substrate as the substrate; the size of the glass substrate is 3.1cm×2.6cm, and the thickness is 0.2cm; the substrate is cleaned with a cleaning agent and then dried;

[0044] (2) Using polytetrafluoroethylene (PTFE) dispersion liquid, using deionized water as a solvent for the polytetrafluoroethylene dispersion liquid, preparing the dispersion liquid with a mass fraction of 60%, then placing the prepared solution on a magnetic stirrer, and stirring for 3 hours;

[0045] (3) After coating the polytetrafluoroethylene dispersion in the step (2) on the surface of the glass substrate in the step (1), set the spin coating speed as 3000r / min, and the spin coating time is 60s; then Dry at 100°C for 5 minutes under a baking lamp to form a polytetrafluoroethylene coating wi...

Embodiment 3

[0052] This embodiment is basically the same as the above-mentioned embodiment, and the special features are:

[0053] In the above embodiment, a method for preparing metal nanoparticles comprises the following steps:

[0054] (1) Use a glass substrate as the substrate; the size of the glass substrate is 3.1cm×2.6cm, and the thickness is 0.2cm; the substrate is cleaned with a cleaning agent and then dried;

[0055] (2) Using polytetrafluoroethylene (PTFE) dispersion liquid, using deionized water as a solvent for the polytetrafluoroethylene dispersion liquid, preparing the dispersion liquid with a mass fraction of 60%, then placing the prepared solution on a magnetic stirrer, and stirring for 3 hours;

[0056] (3) After coating the polytetrafluoroethylene dispersion in the step (2) on the surface of the glass substrate in the step (1), set the spin coating speed as 3000r / min, and the spin coating time is 60s; then Dry at 100°C for 5 minutes under a baking lamp to form a polyte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com