A method for synthesizing co-doped nickel ferrite soft magnetic material with laterite nickel ore

A technology of laterite nickel ore and soft magnetic material, applied in the field of magnetic materials, can solve the problem of high cost and achieve the effects of easy operation, wide source and high comprehensive utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] 1. Raw material selection

[0016] The raw material is saprolite type lateritic nickel ore, and its chemical analysis results are shown in Table 1:

[0017] Table 1: Chemical composition of saprolite-type lateritic nickel ore (wt.%)

[0018]

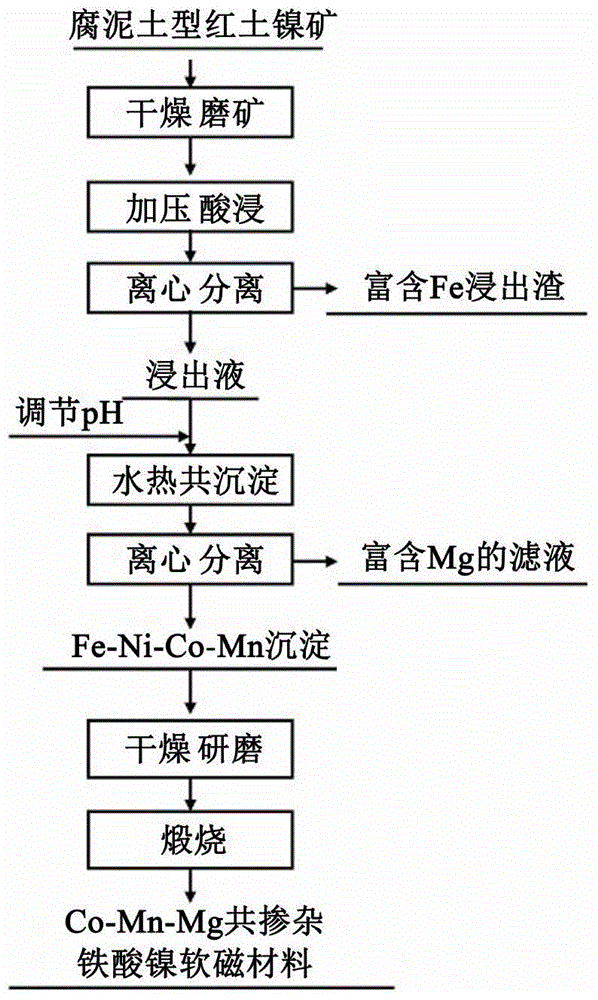

[0019] 2. Synthesis steps: see figure 1

[0020] (1) Dry the saprolite-type lateritic nickel ore in an oven at 105°C for 24 hours, and then grind the ore to 100 mesh.

[0021] (2) Mix finely ground saprolite-type lateritic nickel ore with 2.5mol·L -1 Hydrochloric acid was added into the reaction kettle according to the solid-to-liquid ratio of 1g:6ml, the reaction kettle was sealed, and it was heated to 200°C for 8 hours. After cooling to room temperature, solid-liquid separation is carried out to obtain a leaching solution with n(Fe):n(Ni, Co, Mn)=2.0 in the solution.

[0022] (3) Put the above leaching solution in the reaction kettle, and use 1.0mol·L -1 Adjust the pH of the NaOH solution to neutral (7.0), seal the reac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com