Eccentric crack type variable-compression-ratio mechanism

A bell crank type, compression ratio technology, applied in the direction of mechanical control, mechanical equipment, engine control, etc., can solve the problems of compression ratio conversion control accuracy, reduced reliability of mechanical components, increased manufacturing costs, etc., to optimize the working process, improve performance, minor changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

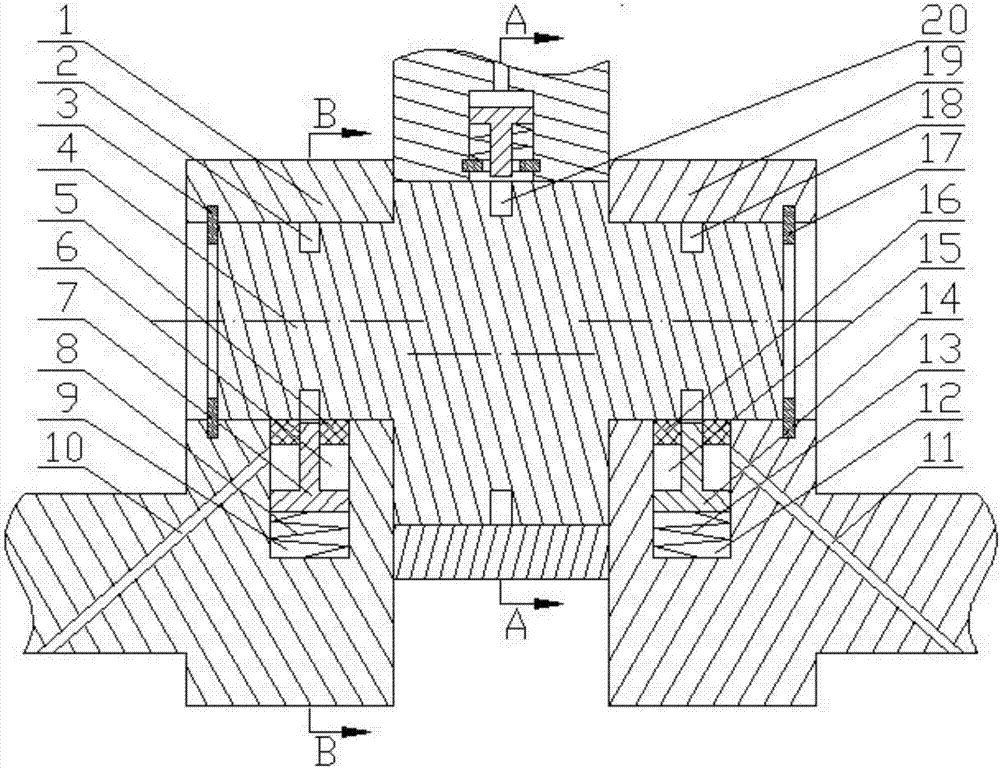

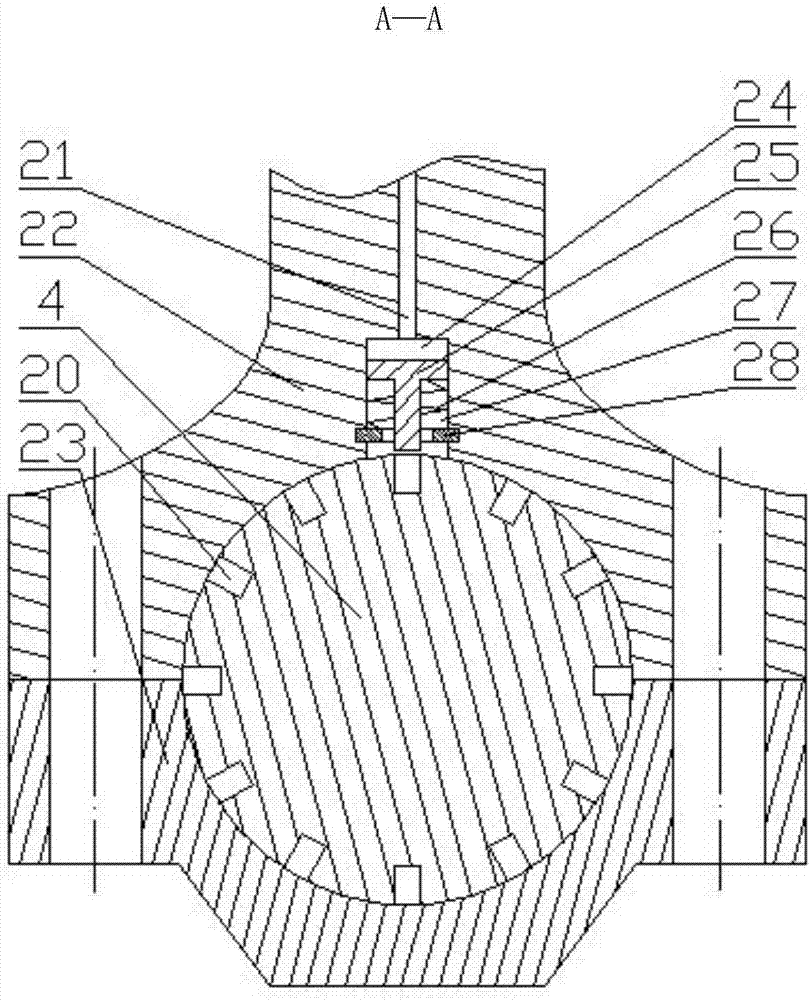

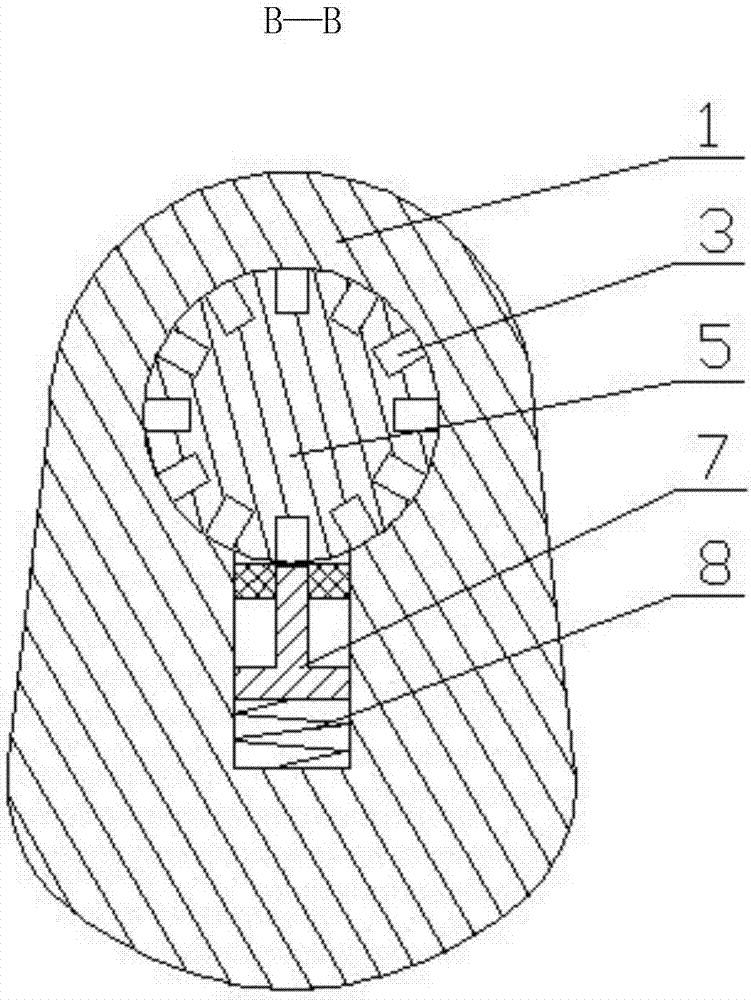

[0025] Attached below Figure 1-3 The present invention is described in detail:

[0026] Refer to attached figure 1 , 2 :

[0027]The present invention consists of crankshaft left body (1), locking pin hole a (2), snap ring a (3), crank pin (4), sealing ring a (5), oil cavity a (6), locking pin a (7), spring a(8), lock pin installation hole a(9), oil passage a(10), oil passage b(11), lock pin installation hole b(12), spring b(13), Lock pin b(14), oil chamber b(15), sealing ring b(16), snap ring b(17), lock pin hole b(18), crankshaft right body (19), lock pin hole c (20), oil passage c(21), connecting rod(22), connecting rod cover(23), oil chamber c(24), locking pin c(25), spring c(26), locking pin installation hole c(27) and snap ring c(28).

[0028] Refer to attached figure 1 , 3 :

[0029] Described crankshaft is combined crankshaft, is made up of crankshaft left body (1), crank pin (4) and crankshaft right body (19);

[0030] The crank pin (4) is connected to the ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap