Detection system and method of steel bar tension force of vertical prestress of web of concrete box girder bridge

A vertical prestressing, concrete box girder technology, applied in force/torque/work measuring instruments, measuring devices, instruments, etc., can solve the problem of uncertain effective tension, difficulty in secondary tension displacement, and large retraction and other problems, to achieve the effect of convenient connection or separation, improvement of rapid monitoring ability, and prevention of failure of concrete structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment A

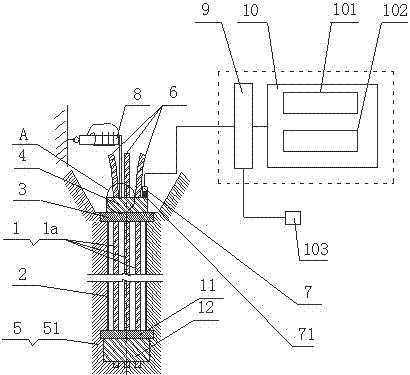

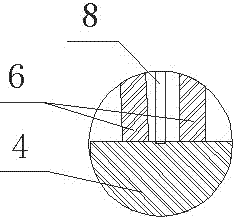

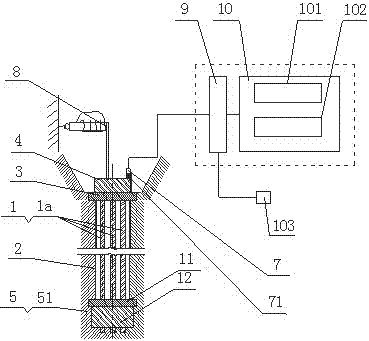

[0044] ① The construction unit installs ordinary steel bars according to the design drawings of the concrete box girder bridge, in which the steel strand 1 is covered with the bellows 2, and the anchor plate 3 and the anchorage 4 are installed at the upper and lower ends of the bellows 2, and the steel strand 1 passes through Anchorage 4, reserve 6 lengths of the exposed section of steel strand vertical prestressed reinforcement, first set the formwork according to the drawing during construction, pour the box girder bridge web concrete 51, form the concrete box girder bridge web 5 after the concrete reaches the strength, and then The tensioned steel strand 1 passes through the anchorage 4 so that the steel strand 1 is subjected to tension, and becomes the vertical prestressed tendon 1a of the steel strand. The outer end of the vertical prestressed tendon 1a of the steel strand is provided with an exposed section as required. The length of the exposed section must be reserved w...

Embodiment B

[0047] ① After the construction operation, the process of transforming the steel strand 1 into the vertical prestressed tendon 1a of the steel strand is completed. According to the requirements, the diameter and number of the vertical prestressed tendon 1a of the steel strand are determined by the model of the anchorage 4, and JYM15 .2-5 model anchorage 4 is taken as an example, the diameter of the steel strand 1 is 15.2 mm, and the number of 1 steel strand is 5.

[0048] ②Acceleration sensor 7 is fixedly installed on the end face of anchorage 4 through magnetic suction seat 71 (or rubber mud or gypsum mud). The vibration direction of acceleration sensor 7 should be parallel to the length direction of the vertical prestressed tendon 1a of the steel strand, as shown in the attached drawing As shown, the acceleration sensor 7 is a YD-65 type product, the charge sensitivity is 414.15, the frequency measurement range is 5 to 2000 Hz, and there is a matching magnetic suction seat 71...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com