LCM liquid crystal display module structure which prevents backlight film from displacement

A liquid crystal display module and backlight module technology, applied in optics, nonlinear optics, instruments, etc., can solve problems such as easy scratches, easy scratches on the light-emitting surface of the light guide plate 4, and affect the display effect of the product, so as to avoid white spots And bright edge, improve the effect of reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The preferred embodiments provided by the present invention will be specifically described according to the accompanying drawings.

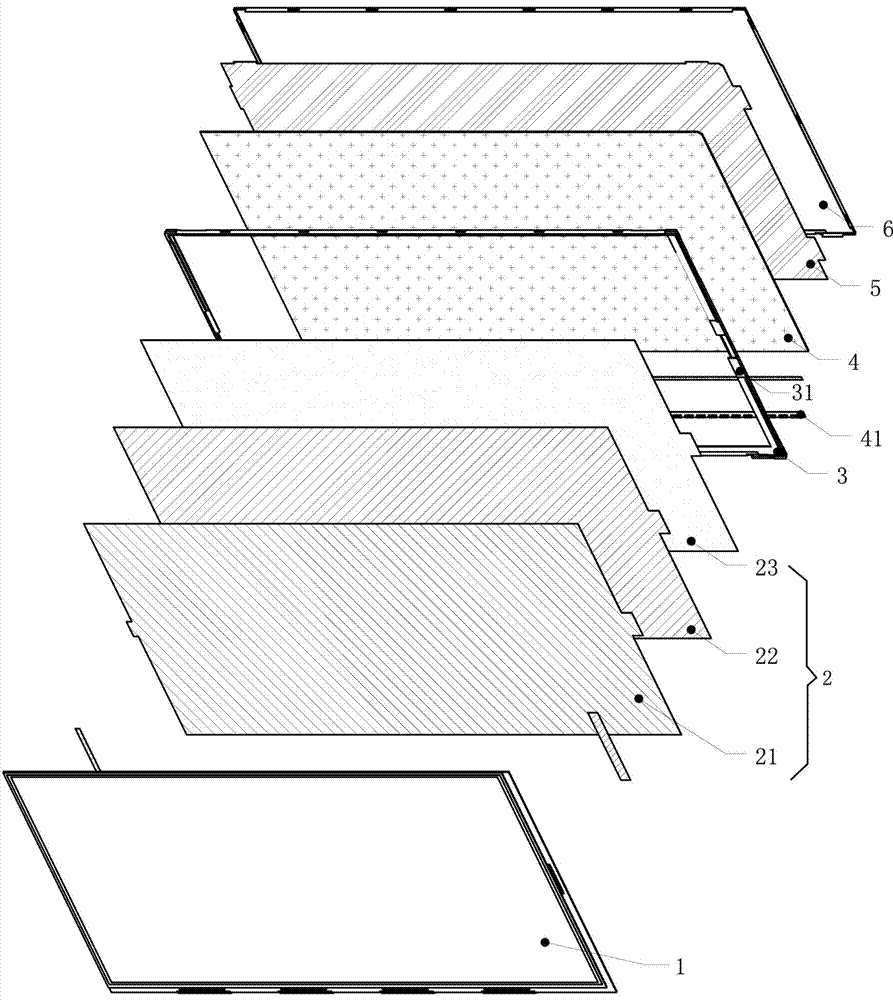

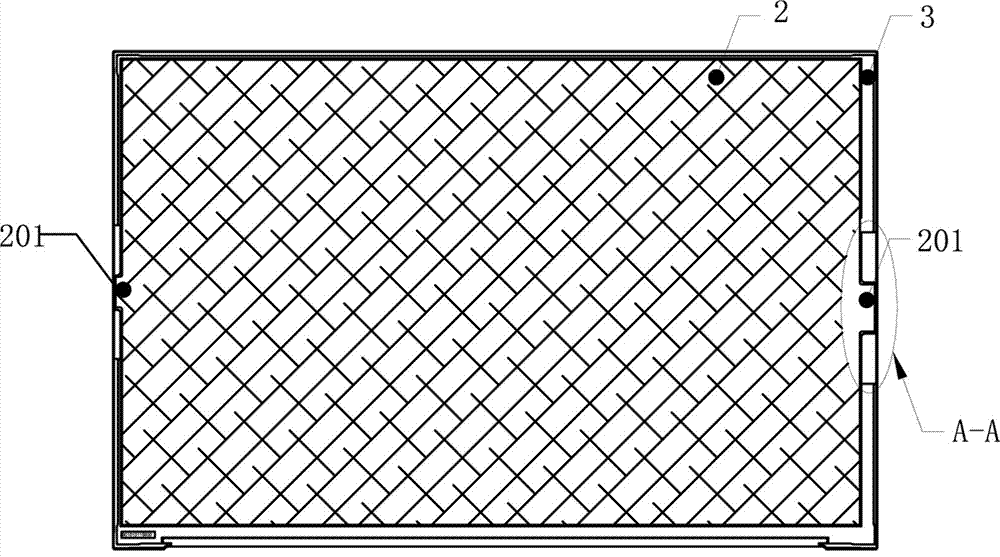

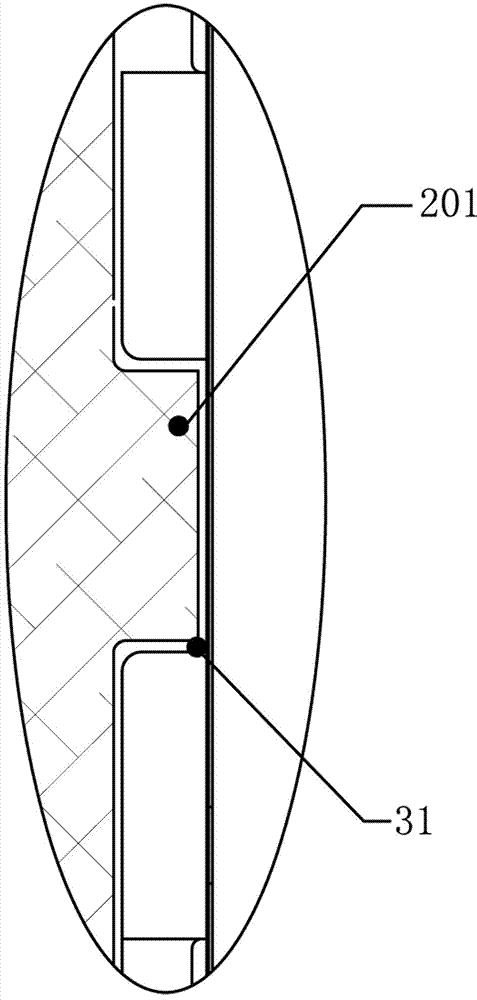

[0022] Figure 4 to Figure 7 , is a schematic diagram of the structure of an LCM liquid crystal display module that prevents the displacement of the backlight film material provided by the present invention. Such as Figure 4 to Figure 7 As shown, the structure of the LCM liquid crystal display module includes a FOG liquid crystal display 10, a plastic frame 20 for placing the FOG liquid crystal display 10, and a backlight module 30 located at the back of the FOG liquid crystal display 10. The backlight of the backlight module 30 is A metal back plate 40 is provided for supporting and protecting.

[0023] The backlight module 30 includes a light guide plate 31, the back of the light guide plate 31 is provided with a reflective sheet 32, the light incident side of the light guide plate 31 is provided with a light bar LB311, and the front ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com