Preparation method for soft and hard alternated morphology biomimetic material based on friction performance

A technology of bionic materials and friction properties, applied in the field of bionic materials, to achieve simple methods, good economic and social benefits, and controllable friction properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

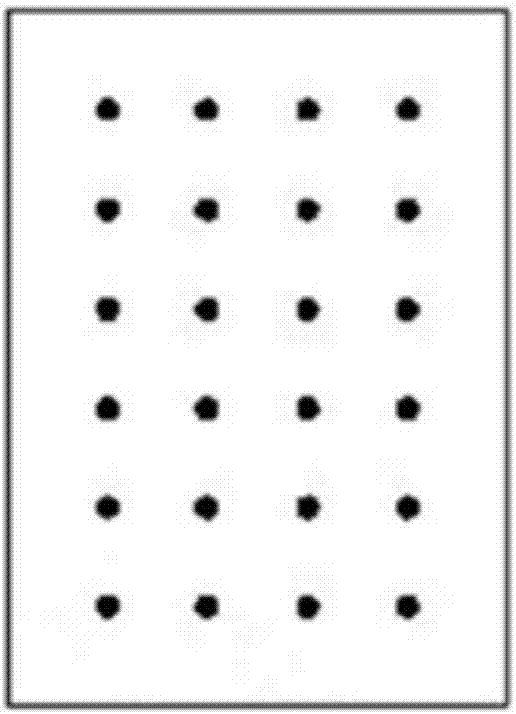

[0075] It is known that the elastic modulus of the soft material is 160Mpa, the friction coefficient is 0.2, the elastic modulus of the hard material is 1200Mpa, and the friction coefficient is 0.1, choose as Figure 1a , Figure 5 For the soft-hard interphase biomimetic material shown, if it is desired to prepare a soft-hard interphase biomimetic material with a friction coefficient of 0.15, the specific preparation method is as follows:

[0076] Step 1. Determine the ratio of soft and hard materials. According to the requirements of material friction characteristics, that is, the friction coefficient f of the bionic material with soft and hard phase morphology, an appropriate ratio of soft and hard materials is selected. The ratio of soft and hard materials can be calculated according to the following formula:

[0077]

[0078] Among them, c% is the volume percentage of the soft material, f is the friction coefficient of the soft and hard bionic material, f s is the fri...

Embodiment 2

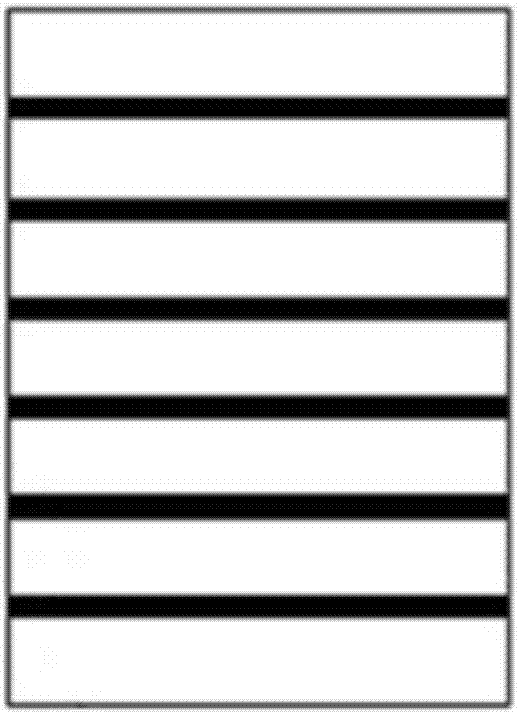

[0087] It is known that the elastic modulus of soft material is 180Mpa, the friction coefficient is 0.21, the elastic modulus of hard material is 1000Mpa, and the friction coefficient is 0.11, choose as Figure 1b , Image 6 For the soft-hard interphase biomimetic material shown, if it is desired to prepare a soft-hard interphase biomimetic material with a friction coefficient of 0.14, the specific preparation method is as follows:

[0088] Step 1: Determine the ratio of soft and hard materials. According to the requirements of material friction characteristics, that is, the friction coefficient f of the bionic material with soft and hard phase morphology, an appropriate ratio of soft and hard materials is selected. The ratio of soft and hard materials can be calculated according to the following formula:

[0089]

[0090] Among them, c% is the volume percentage of the soft material, f is the friction coefficient of the soft and hard bionic material, f s is the friction co...

Embodiment 3

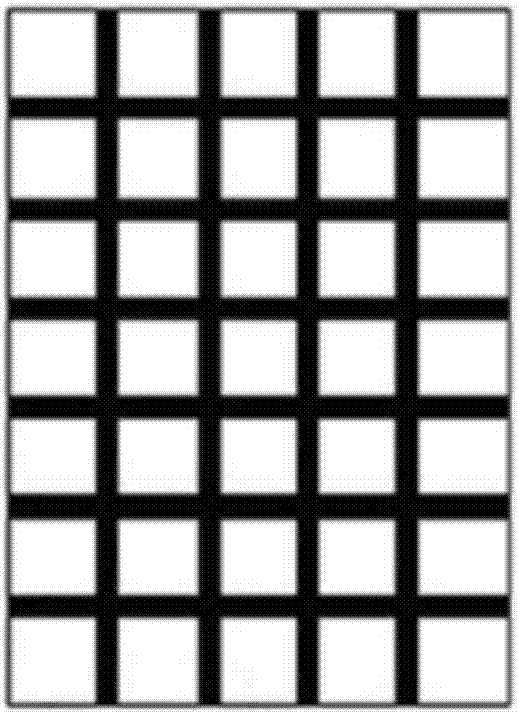

[0099] It is known that the elastic modulus of soft material is 150Mpa, the friction coefficient is 0.19, the elastic modulus of hard material is 1100Mpa, and the friction coefficient is 0.12. Figure 1c , Figure 7 For the soft-hard interphase biomimetic material shown, if it is desired to prepare a soft-hard interphase biomimetic material with a friction coefficient of 0.16, the specific preparation method is as follows:

[0100] Step 1: Determine the ratio of soft and hard materials. According to the requirements of material friction characteristics, that is, the friction coefficient f of the bionic material with soft and hard phase morphology, an appropriate ratio of soft and hard materials is selected. The ratio of soft and hard materials can be calculated according to the following formula:

[0101]

[0102] Among them, c% is the volume percentage of the soft material, f is the friction coefficient of the soft and hard bionic material, f s is the friction coefficie...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Elastic modulus | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com