Seed husking device for green beans

A threshing device, green bean technology, applied in application, food science, food processing and other directions, can solve problems such as low efficiency, easy to suffer from frostbite, etc., and achieve the effects of improving stability, saving energy, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below by means of specific embodiments:

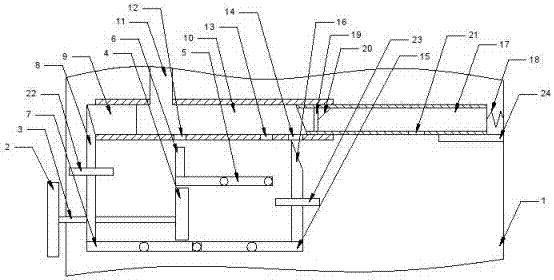

[0022] The reference signs in the drawings of the description include: frame 1, fan blade 2, rotating shaft 3, cam 4, first hinged arm 5, cutter 6, second hinged arm 7, first wedge block 8, push rod 9 , transport pipe 10, feed pipe 11, notch 12, waste material port 13, limit hole 14, third articulated arm 15, second wedge block 16, cutting pipe 17, first compression spring 18, movable plate 19, the first Two compression springs 20, a discharge port 21, a first guide plate 22, a second guide plate 23, and a support plate 24.

[0023] The embodiment is basically as attached figure 1As shown: the green bean threshing device includes a frame 1, on which a power mechanism, a pushing mechanism and a cutting mechanism are arranged, and the power mechanism includes a fan blade 2, a rotating shaft 3, a cam 4, a first articulated arm 5 and a cutter 6 , the two ends of the rotatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com