Casting die avoiding press shell interior shrinkage porosity

A technology of casting mold and shrinkage porosity, which is applied in the field of metal casting and casting, can solve the problems of shrinkage porosity in the center of the casting, thick structure, long feeding distance, etc., to prevent air leakage of the casting and prevent shrinkage on the surface of the casting The effect of loosening and eliminating shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

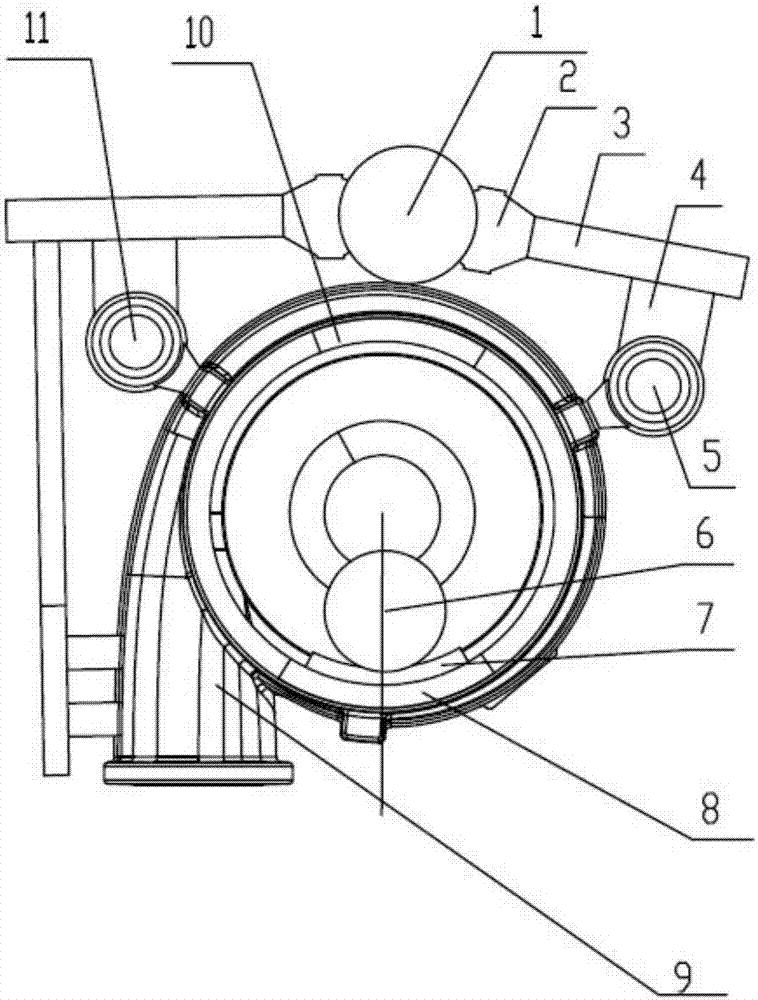

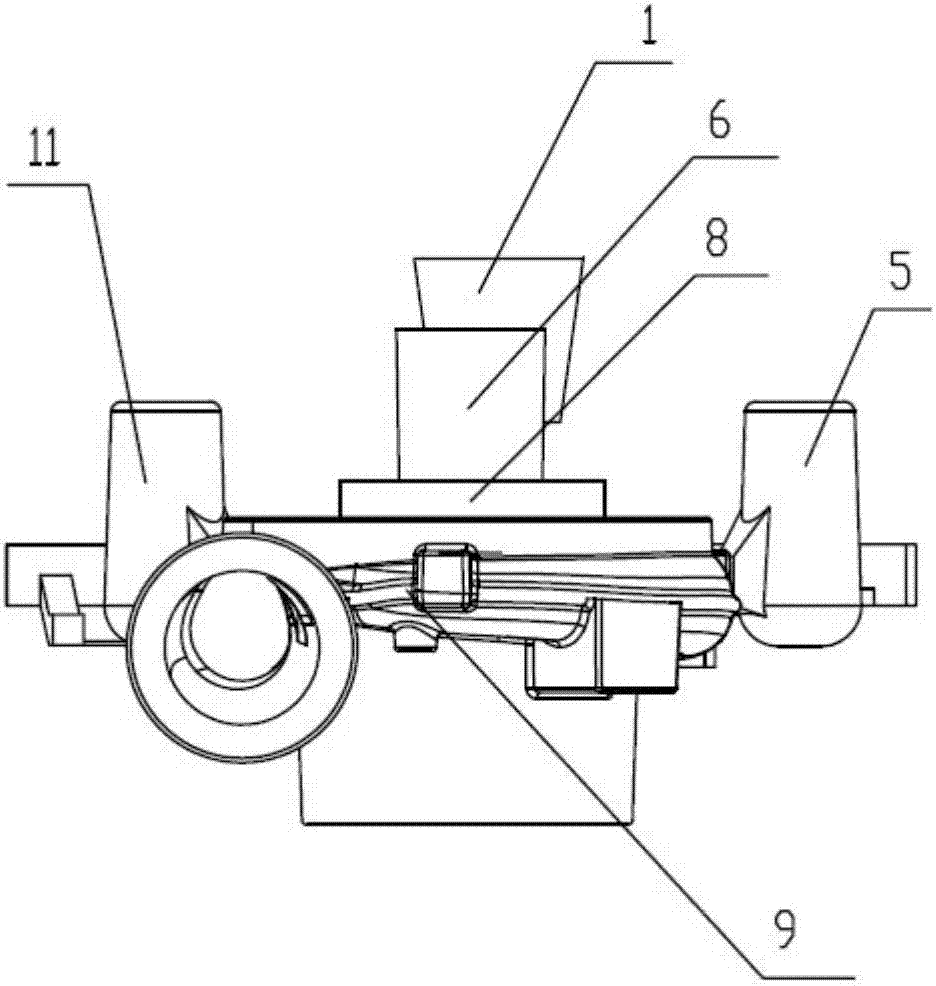

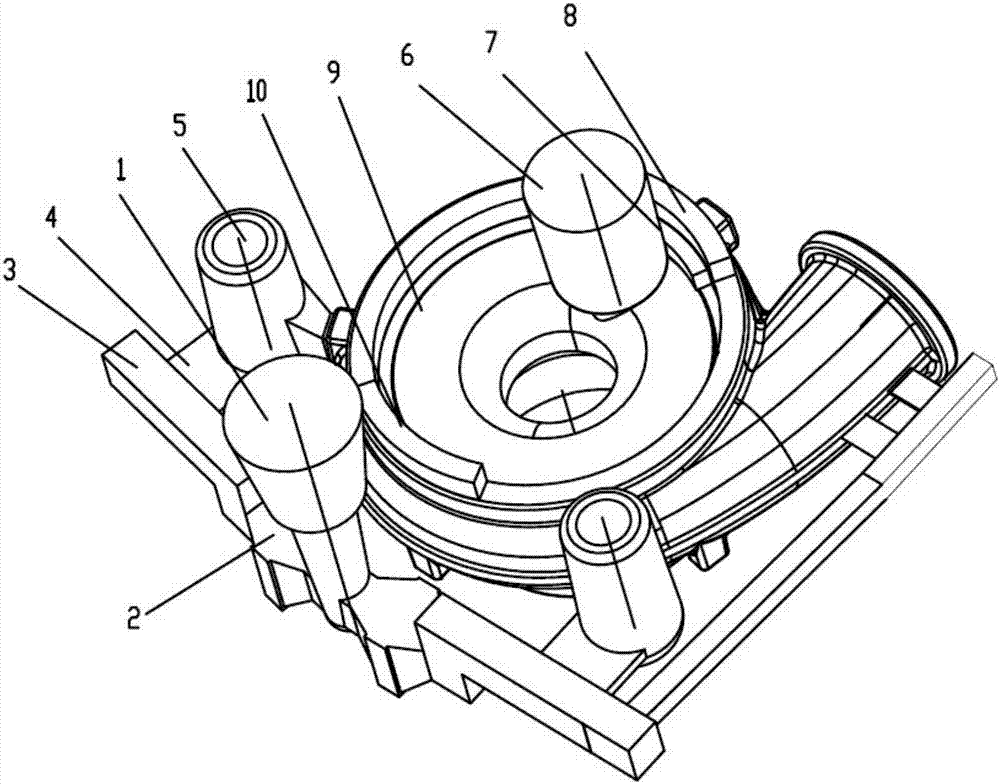

[0014] This embodiment solves the casting mold with shrinkage inside the pressure shell such as figure 1 , 2 , 3, the pressure shell main body mold 9 with the required internal cavity is in the shape of a volute, and the outer side of the pressure shell main body mold 9 away from the outlet of the volute has a vertical runner 1 with an upper end opening, and the vertical runner 1 passes through the The horizontal runners 3 extending to both sides communicate with the two inner runners 4 facing the pressure shell body mold 9 respectively. The filter block 2 is passed between the vertical runner 1 and the horizontal runner 3 . The two inrunners 4 communicate with the radial inlet of the pressure shell main body mold 9 after respectively passing through the inlet risers 5 and 11 opening upward. The angle between the two radial inlets is 120°, and two arc-shaped cold irons 8,10 adjacent to the outer circle on the disc upper surface of the pressure shell body mold 9 are provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com