Ship

A hull and bow technology, applied in the field of boats with improved hulls

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

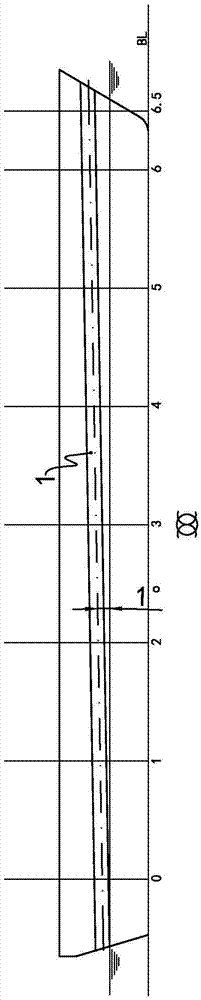

[0036] see figure 1 , this is a schematic diagram of the starboard side of the hull of a small ship. Due to the short length of the ship, only 6.5 stations are used in the figure. It can be seen that there is an inner groove 1 from the bow to the stern on the freeboard, and it is also symmetrical on the invisible port side The set has the same inner groove. The angle α between the centerline of the inner groove 1 and the waterline is shown in figure 1 The center is marked as 1°.

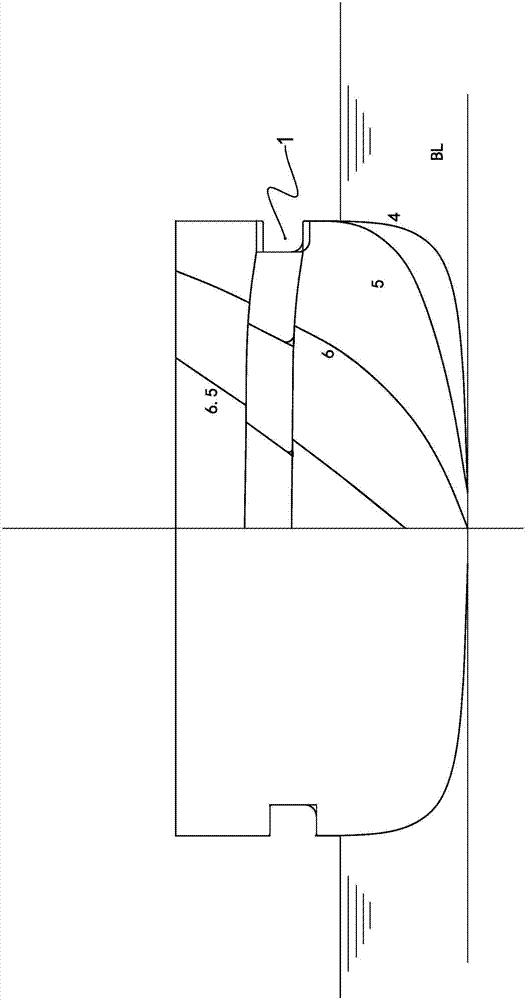

[0037] see figure 2 , it can be seen that the shape of the inner groove 1 at each station, the groove width is the same at each station, the groove depth is at the stern plate, and the same at stations 0 to 5. The groove depth at the post is zero.

[0038] see image 3 with Figure 4 , visible at station 6.5 and the shape of the inner groove 1 at station 4.

[0039] see Figure 5 with Image 6 , the shape of the internal groove 1 on the hull of the first embodiment can be seen.

no. 2 example

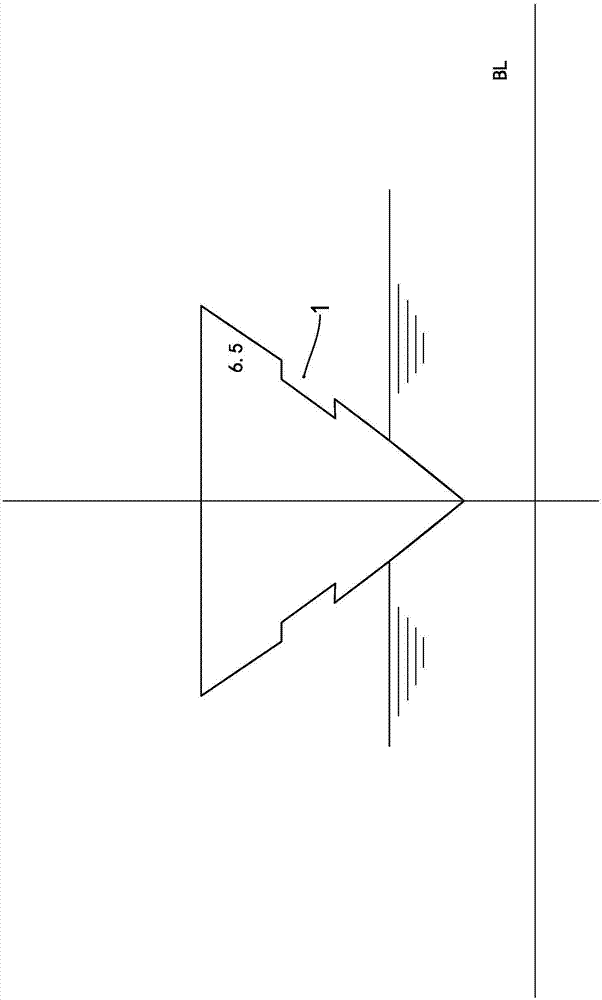

[0041] The following only describes the differences between this example and the previous example, see Figure 7 , the ship type, hull size, and speed of this example are different from those of the previous example. Therefore, the angle α between the centerline of the inner groove 1 and the waterline is shown in Figure 7 The label in is -1°.

no. 3 example

[0043] see Figure 8 , Figure 8 It is a typical cross-sectional schematic diagram of an ocean-going ship, which has a relatively high freeboard. Therefore, in this example, three internal grooves are arranged in parallel on the freeboard to minimize the area of head-on-wave resistance during surfing .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com