Method of continuous phase transition of heterogeneous system in preparation of inorganic powder through hydrothermal method

An inorganic powder, multiphase system technology, applied in inorganic chemistry, chemical instruments and methods, nanotechnology for materials and surface science, etc. need to wait

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

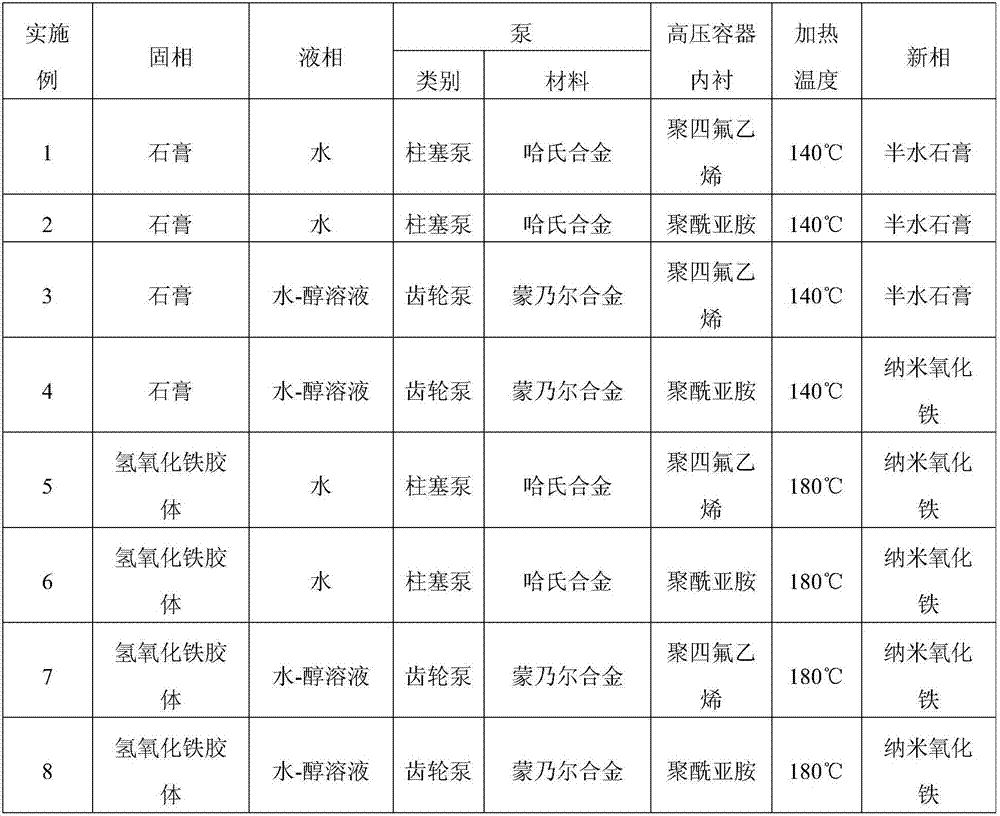

[0013] One embodiment of the present invention is: the method for preparing the continuous phase transition of multi-phase system in inorganic powder by hydrothermal method, mixing the solid phase and liquid phase into a slurry, and sending the slurry into a high-pressure container at high pressure with a pump; The high-pressure container is heated, part of the liquid phase changes into a gas phase, and the solid phase changes into a new solid phase; the reaction product is continuously discharged from the high-pressure container through the pressure lock device into the decompression chamber, and the liquid phase is transformed into a gas phase in the decompression chamber , through a centrifuge, gas-solid separation to obtain a solid product; the gas is condensed into a liquid phase and reused. Specific examples are shown in the table below.

[0014]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com