Recovery and separation device of vinyl chloride-vinyl acetate copolymer resin polymeric unreacted monomers and a method

A technology of vinyl chloride copolymer resin and separation equipment, which is applied in the chemical industry, can solve the problems such as self-polymerization affecting the normal operation of the recovery device, and achieve the effect of solving the problem of separate condensation and recycling, reducing cooling capacity consumption, and reducing monomer consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

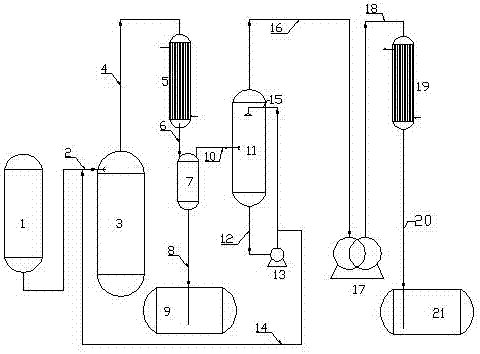

[0022]Example: The slurry is discharged from the discharge pipe at the bottom of the polymerization tank to the recovery tank after the reaction of the polymerization tank is completed during the production of vinyl chloride copolymer resin. The main components of the slurry are water, vinyl chloride resin, and unreacted monomer vinyl chloride gas phase. In the gas phase with vinyl acetate, the slurry temperature is around 45-65°C, and the solid content is 20-30%. The slurry contains residual dispersant, and the slurry enters from the tangential direction of the upper part of the recovery tank, which is beneficial to prevent foam and resin splashing due to the impact of the slurry on the liquid surface of the slurry. When recovering unreacted monomers, the recovery of the gas phase will take the foam away. The entrained resin particles and recovered gas phase in the foam enter the next process; the water and vinyl chloride resin in the slurry are temporarily left in the recover...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com