Mounting structure and method used for pre-burying Halfen groove into concrete member

A technology for installing structure and concrete, which is applied in building construction, building material processing, construction and other directions, can solve the problems of difficult installation and disassembly, prone to inclination, loosening, waste of steel bars, etc. The effect of fixing or dismantling, reducing the construction cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

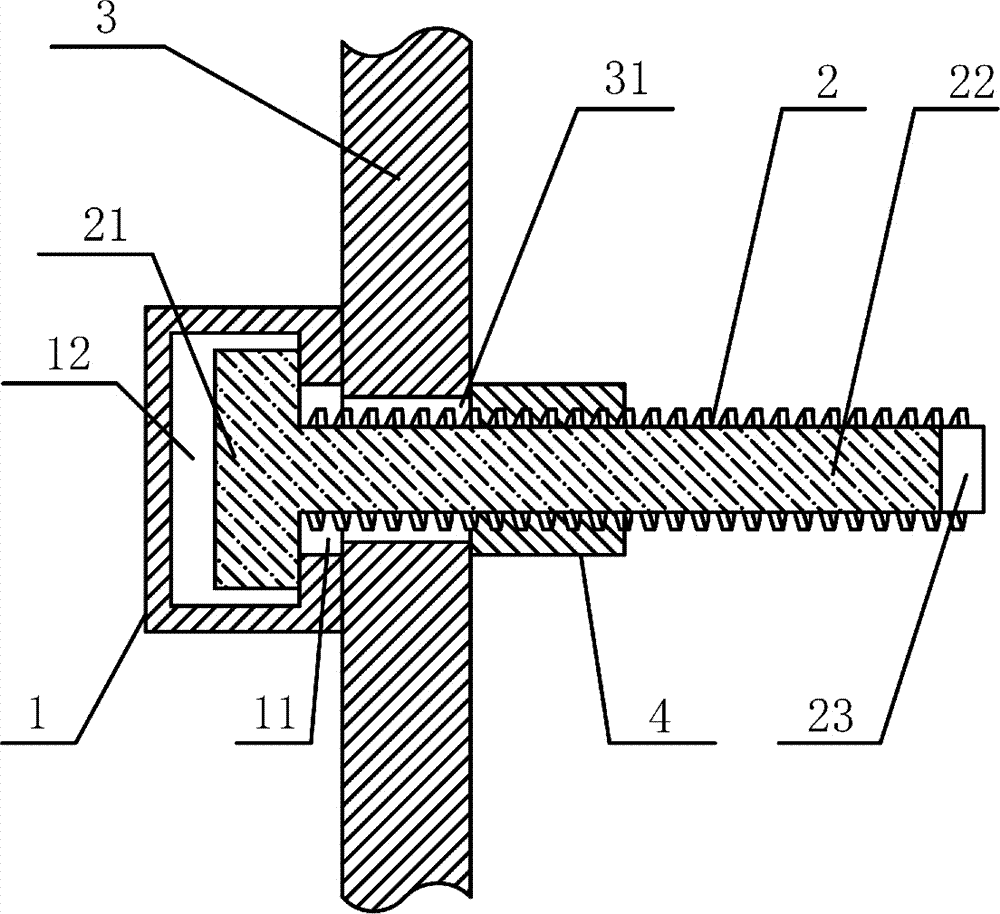

[0043] As shown in Fig. 1 (a) and Fig. 1 (b), a kind of installation structure for pre-embedding the Hafen groove into the concrete member of the present invention is used to pre-embed the Hafen groove 1 into the concrete member, including HALFEN slot 1, T-bolt 2, template 3, nut 4; the bolt head 21 of the T-bolt 2 can be clamped in the cavity 12 of the HALFEN slot 1 and can be removed from the cavity 12, T-shaped The bolt rod 22 of the bolt 2 passes through the notch 11 of the Hafen slot 1; the cavity 12 of the Hafen slot 1 is filled with solid fillers that are easily broken or dragged out; the slot of the Hafen slot 1 The width of the mouth 11 is smaller than the width of the groove cavity 12, and one T-shaped bolt 2 is arranged every 30cm-150cm along the groove 11, and at least two T-shaped bolts 2 are arranged for each Hafen groove 1; The position corresponding to the position of the T-bolt 2 is set to be matched with a template hole 31 for the bolt rod 22 to pass through,...

Embodiment 2

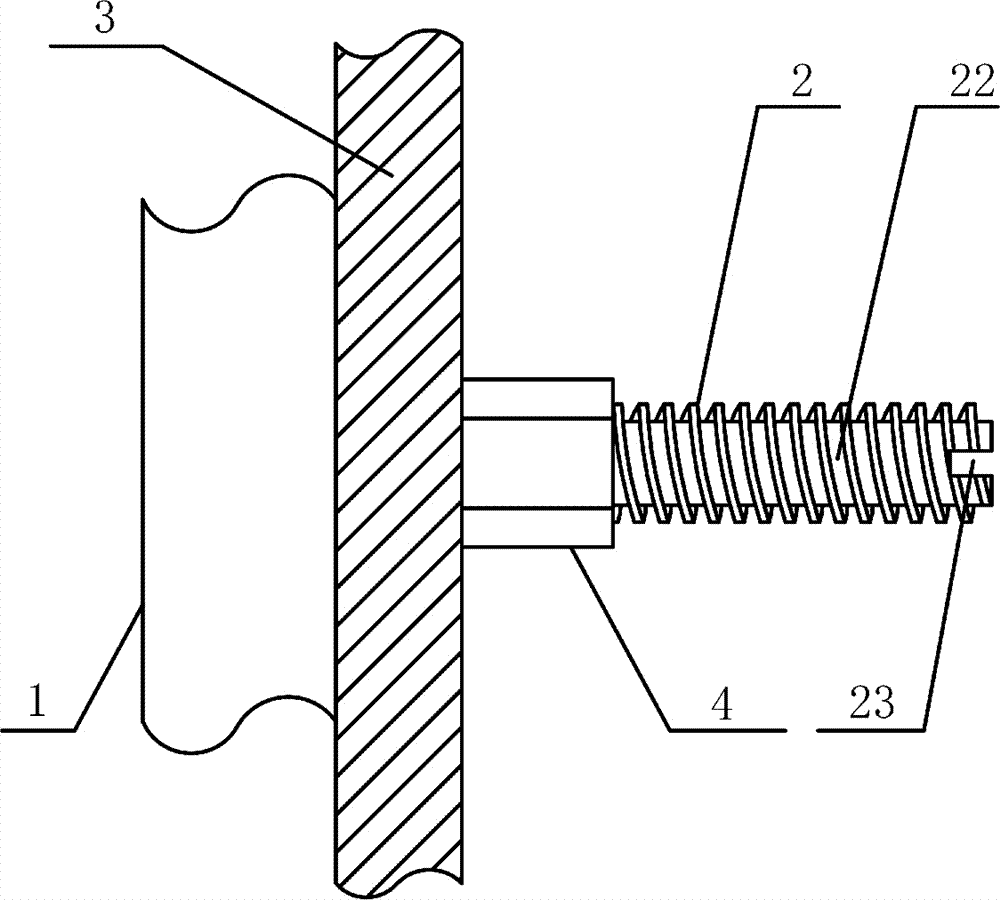

[0045] like figure 2 As shown, an installation structure for pre-embedding a Hafen groove into a concrete member of the present invention is based on Embodiment 1, and the nut 4 is improved from a common hexagonal nut to a hexagonal nut at the upper part and a wing at the lower part. Shaped part of the composite structure nut.

Embodiment 3

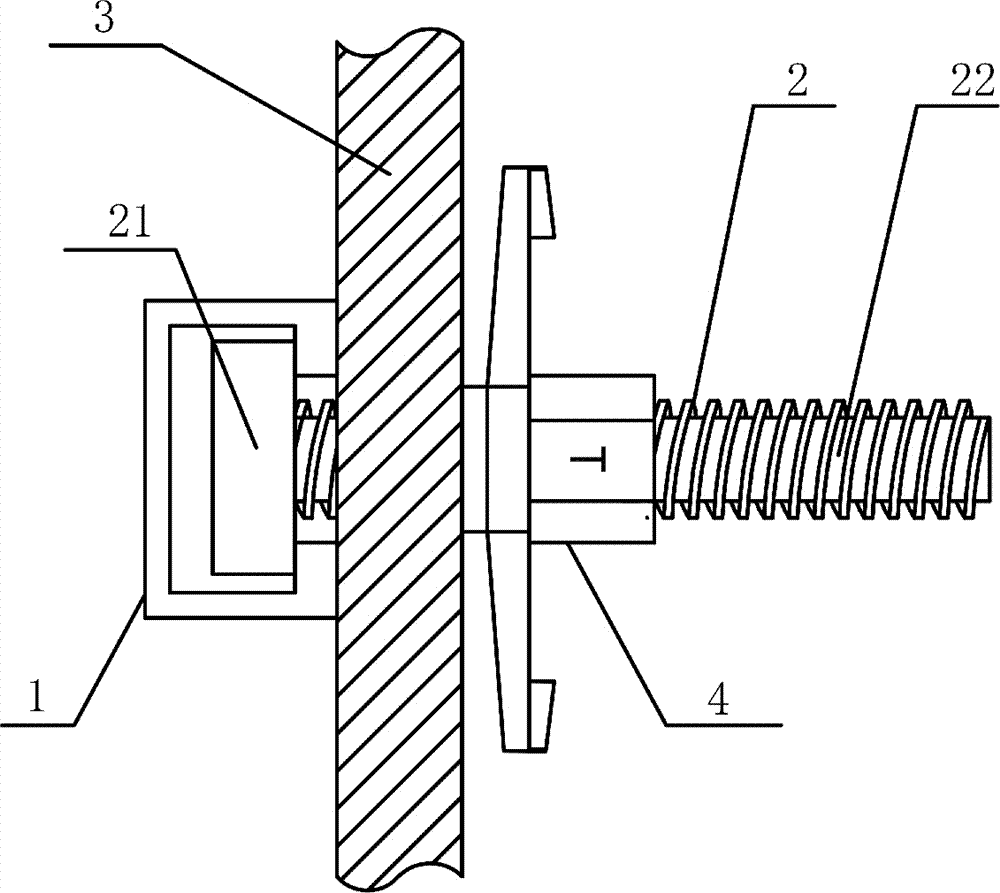

[0047] like image 3 As shown, a kind of installation structure for pre-embedding the Hafen groove into the concrete member of the present invention is based on Embodiment 1, and the nut 4 is improved from a common hex nut to a common wing nut; On the outside of the opposite side of the notch 11 of the Hafen groove 1, an anchor rod 6 for preventing the Hafen groove 1 from falling off from the concrete member is installed. The anchor rod 6 is "I-shaped", perpendicular to the Hafen groove 1 And rigidly connected with the Hafen groove 1, the length of the anchor rod 6 is 5cm-10cm, the diameter of the anchor rod body 61 is 5mm-15mm, and the anchor rod head 62 is a cylinder or a semicircular sphere with a diameter of 10mm-30mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com