Composite magnetic field sensor and manufacturing process thereof

A composite magnetic field and manufacturing process technology, applied in the field of magnetic field sensors, can solve problems such as the inability to detect a wide range of magnetic fields

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

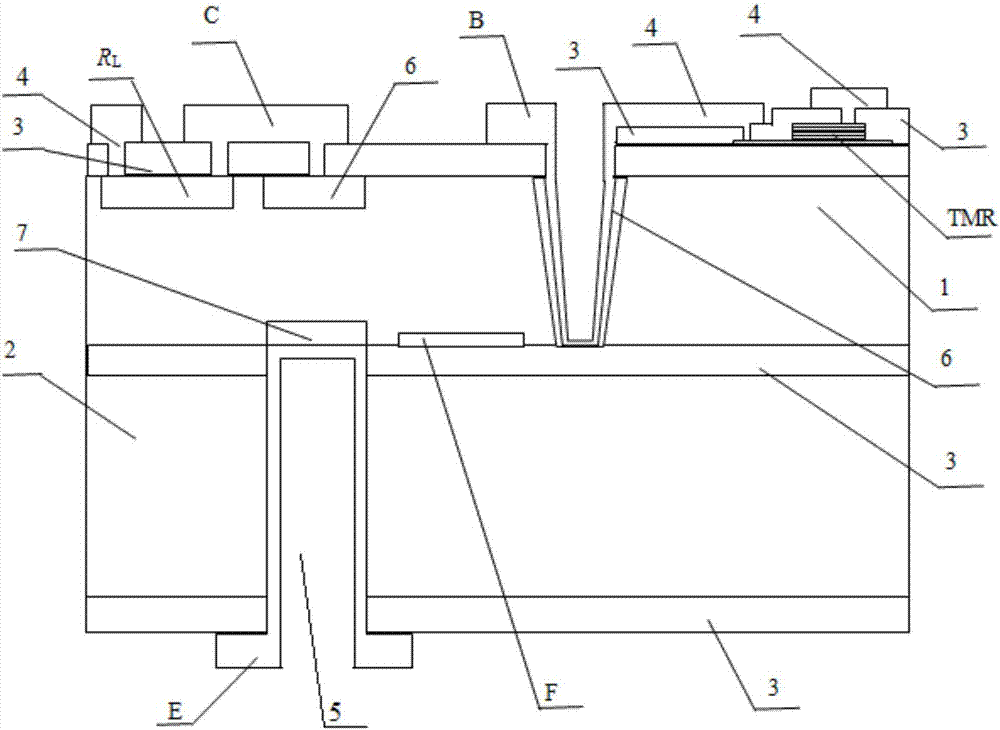

[0067] According to a preferred embodiment of the present invention, the magnetotransistor is a silicon magnetotransistor (SMST).

[0068] In a further preferred embodiment, the magnetotransistor is an NPN silicon magnetotransistor.

[0069] According to a preferred embodiment of the present invention, such as figure 1 As shown, the magnetotransistor includes a first silicon chip 1 and a second silicon chip 2 .

[0070] In a further preferred embodiment, the first silicon wafer 1 and the second silicon wafer 2 are both oriented high-resistance p-type single crystal silicon wafers.

[0071] In a further preferred embodiment, the thickness of the first silicon wafer 1 is 30 μm, and the thickness of the second silicon wafer is 400-425 μm.

[0072] According to a preferred embodiment of the present invention, such as figure 1 As shown, an emitter region is etched on the lower surface of the first silicon chip 1, and an Al lead 4 is etched on the emitter region to form an emitt...

experiment example 1

[0128] Experimental example 1 Composite sensor characteristic test

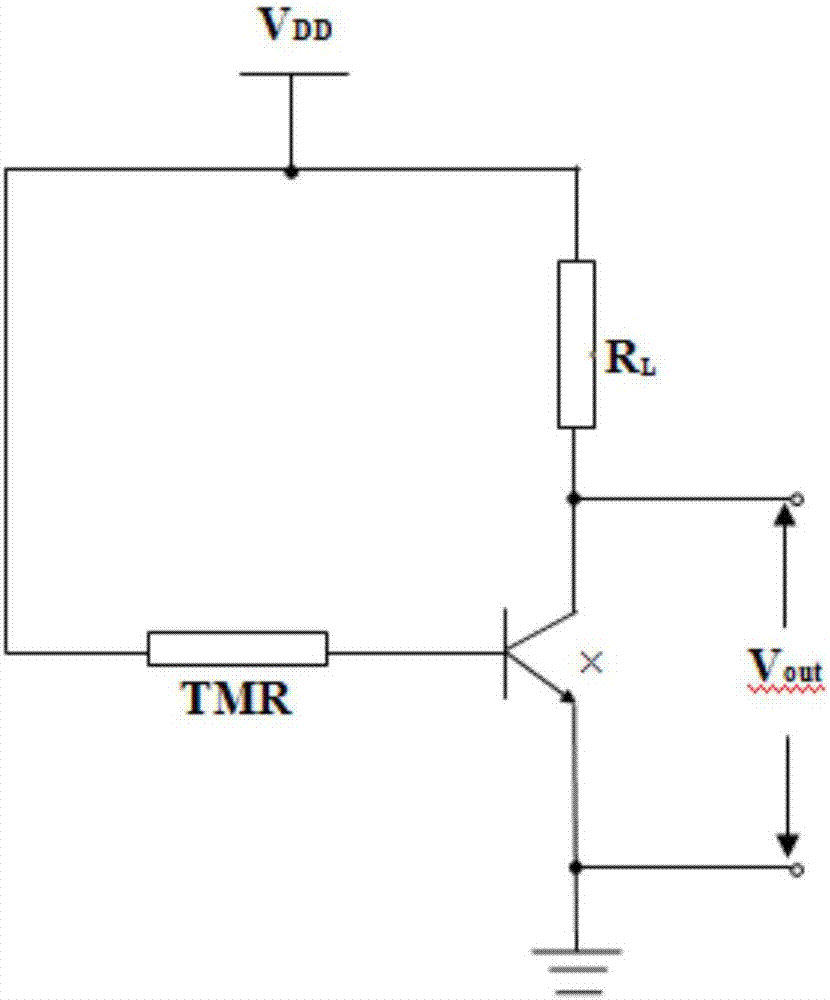

[0129] The composite sensor was tested with the zero-magnetic shielding magnetic field generation system of Beijing Cuihai Jiacheng Magnetic Technology Co., Ltd., and the magnetic field detection sensitivity of the composite sensor was analyzed. After testing, it can be known that the composite magnetic sensor can successfully detect 0.001G S ~10000G S The magnetic induction intensity between.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com