Ceramic powder material dry-process color-blending system and operation method of same

A technology of ceramic powder and working method, which is applied in the directions of mixing operation control, chemical instruments and methods, and selling raw material supply devices, etc. The effect of not easy color deviation, high degree of freedom, and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with specific embodiment:

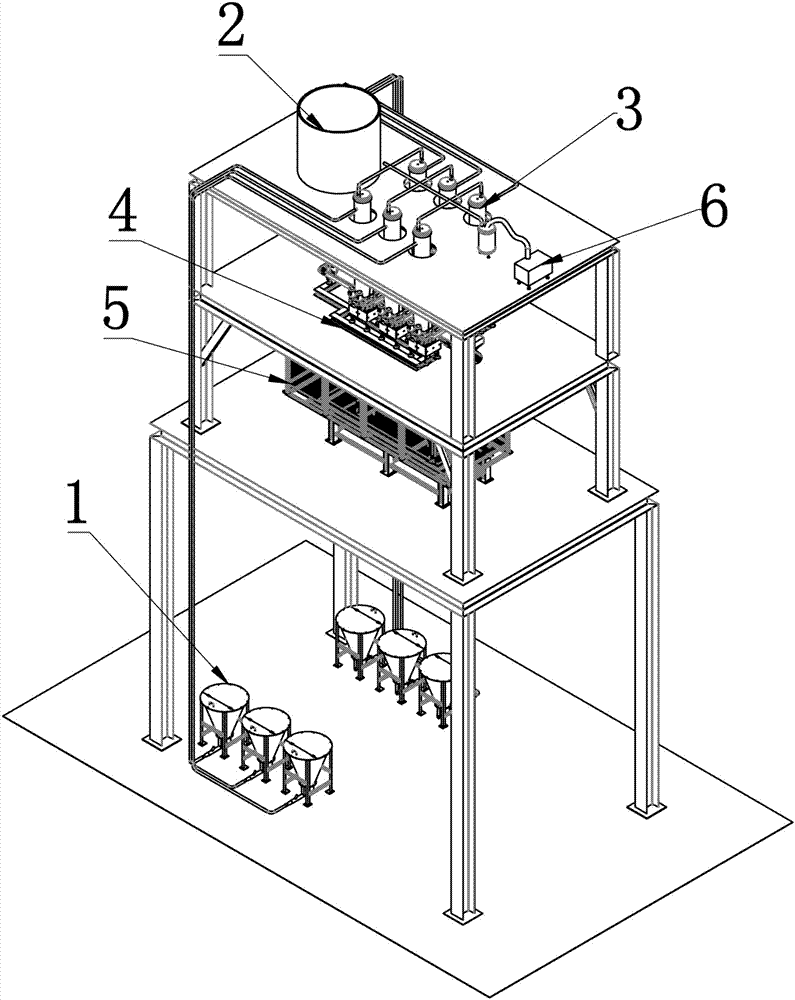

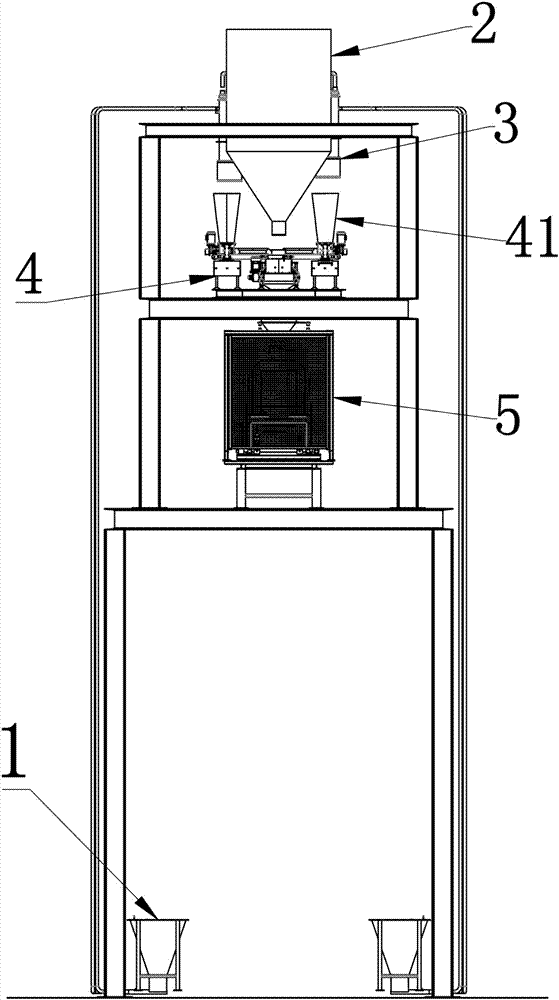

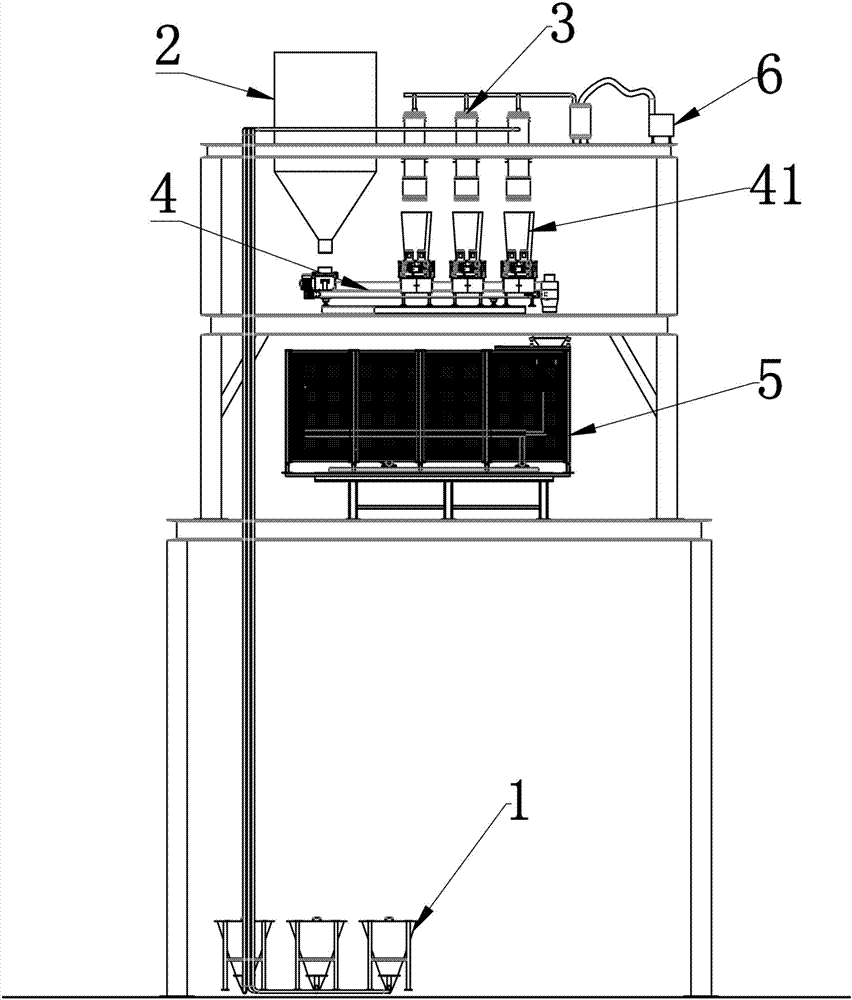

[0018] See attached Figure 1-5 As shown, a ceramic powder dry-process color mixing system includes a plurality of color tanks 1 for storing various color materials, a ceramic silo 2 for storing ceramic materials, a plurality of solenoid valves 3, delivery channels 4 and Mixer 5, wherein the ceramic silo 2 and a plurality of solenoid valves 3 are located on the upper side of the conveying channel 4, specifically, one solenoid valve 3 and the conveying channel 4 are located on the same plane, and the ceramic silo 2 opens to Bottom and the opening of the ceramic silo 2 is provided with a solenoid valve 3 located on the same plane as the conveying channel 4, while the rest of the solenoid valves 3 are all located on the upper side of the conveying channel 4 and are respectively connected to the outlet of the color tank 1. To control the type and amount of color material output...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap