Laser Strengthening Process of Vacuum Pump Compressor Blades

A compressor blade, laser strengthening technology, applied in the field of laser processing, can solve the problems of poor strengthening effect, consumables, large deformation, etc., and achieve the effect of avoiding water erosion, preventing fracture, and preventing differences in gasification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The laser strengthening process of vacuum pump compressor blades, the specific steps are as follows:

[0027] 1) Clean the blade surface with clean water;

[0028] 2) Apply the first absorbent coating evenly on the blade;

[0029] 3) Spray the second absorbent coating on the outside of the first absorbent coating with a spray gun. The side of the blade close to the compressor shaft is the inner side of the blade, and the side of the blade away from the compressor shaft is the outer side of the blade. The second absorbent coating consists of multiple Composed of arcs extending from the inside of the blade to the outside of the blade, the width of the arc is 4mm, and the interval between each arc is 7.5mm;

[0030] 4) apply the constraining layer outside the blade;

[0031] 5) Fix the laser by the fixture;

[0032] 6) Adjust the angle of laser shock strengthening: adjust the angle between the laser light path and the surface of the blade to 20°-85° through the fixture....

Embodiment 2

[0043] Same as Example 1, except that only the first absorber coating is sprayed.

[0044] Table 1 Example 1, Example 2 and the blade fatigue strength parameter table without laser shock

[0045] test group

Embodiment 3

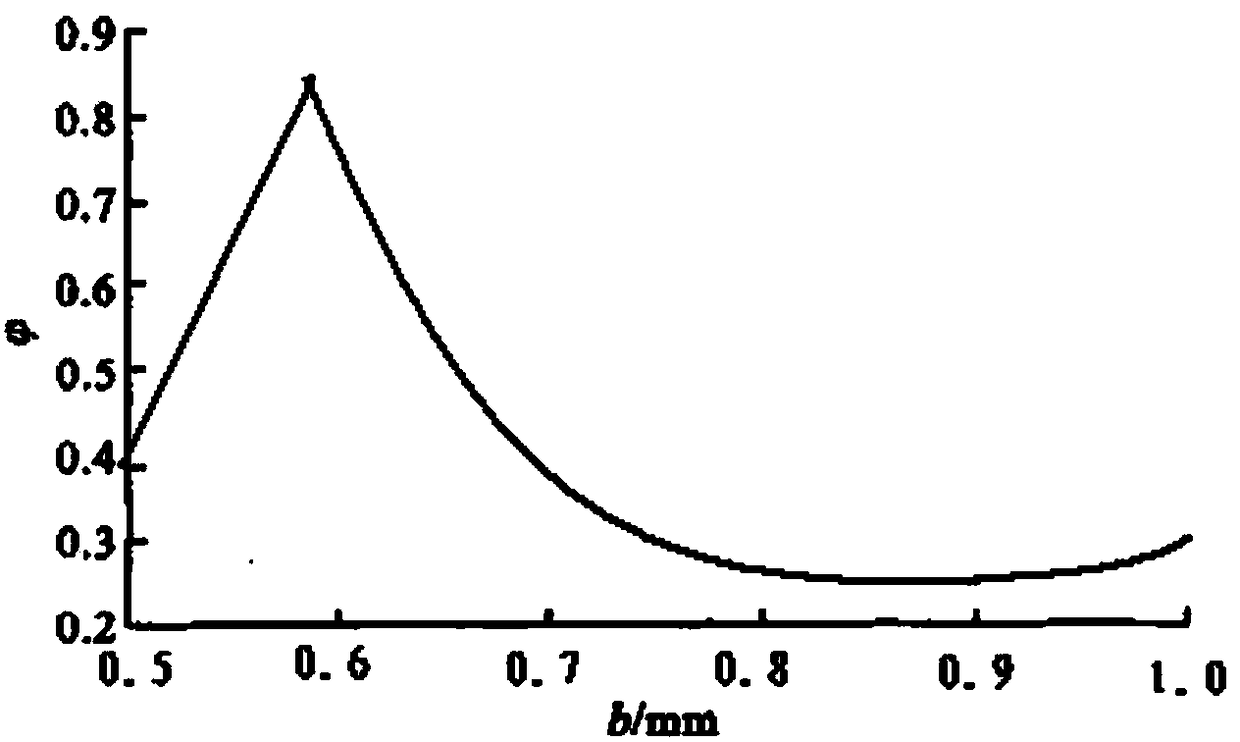

[0047] Same as Example 1, the difference is that the common thickness (b) formed by the second absorbent coating and the first absorbent coating is 0.59 mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com