Installation method for no-stuff-crack window frame

An installation method and window frame technology, applied in the direction of frame fixing, etc., can solve the problems of increasing maintenance costs, affecting construction progress, and difficulty in plugging seams, and achieve the effects of reducing construction difficulty, easy operation and good effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

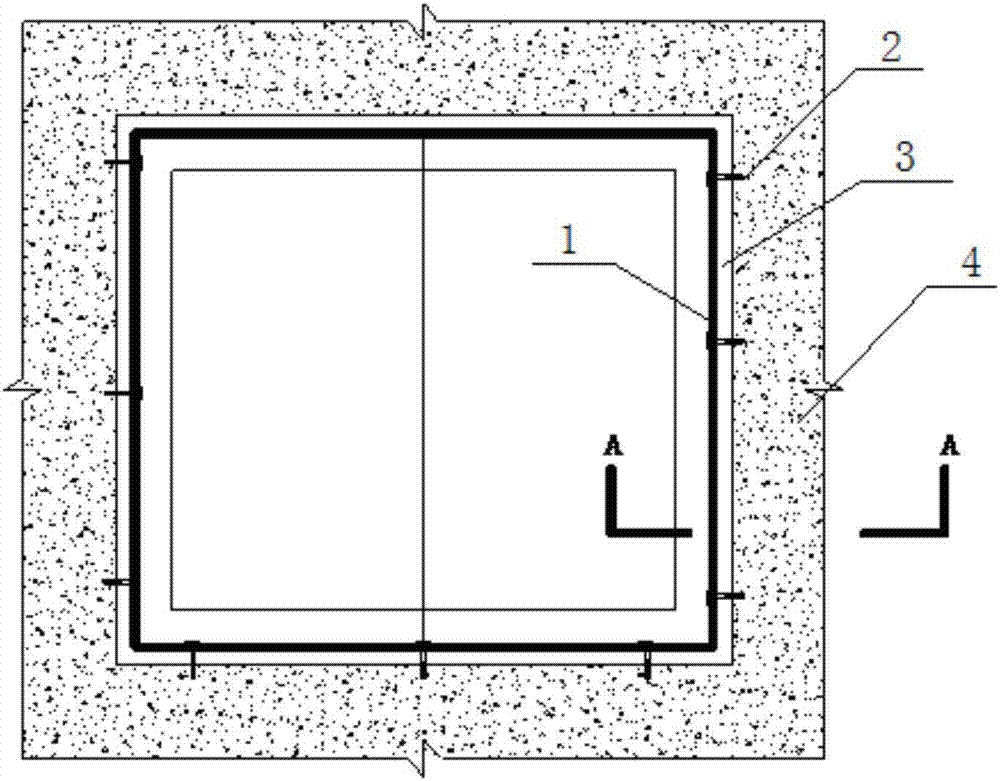

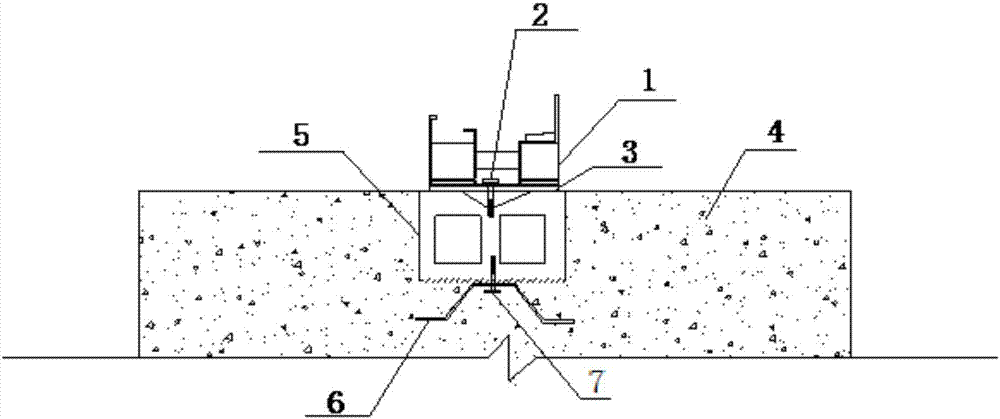

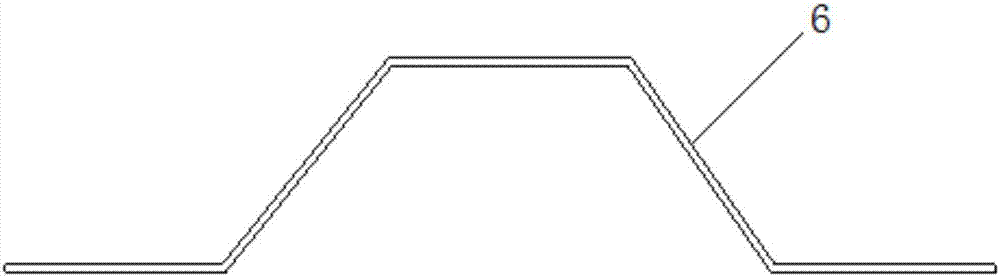

[0014] Referring to the accompanying drawings, a method for installing a non-plugged window frame includes the following construction process: first set the installation position of the fixing part 5 on the pouring formwork of the window opening, ensure that the position of the fixing part 5 does not shift, and install the fixing part 5 It is fixed on the inner side of the formwork, and then the connecting piece 6 effectively connected with the concrete is fixedly connected with the fixing piece 5, the pouring formwork on the four surfaces of the window opening is fixed, and the outer wall 4 is poured with all concrete at one time. After removing the formwork for strength, the fixing parts 5 are integrated with the concrete wall, and the fixing parts 5 are arranged at intervals on the four surfaces of the window opening, and finally the window frame 1 is directly connected with the fixing parts 5 through self-tapping screws 2, and the window The tiny gap 3 between the frame 1 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com