A rock compression fracture prediction method

A prediction method and rock technology, applied in the direction of applying stable tension/pressure to test the strength of materials, measuring devices, instruments, etc., can solve the problems of reducing the macroscopic stiffness of the rock mass, the problem is not solved, and the CT is difficult to achieve, etc., to achieve the design Cleverly conceived, small-scale, high-precision effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

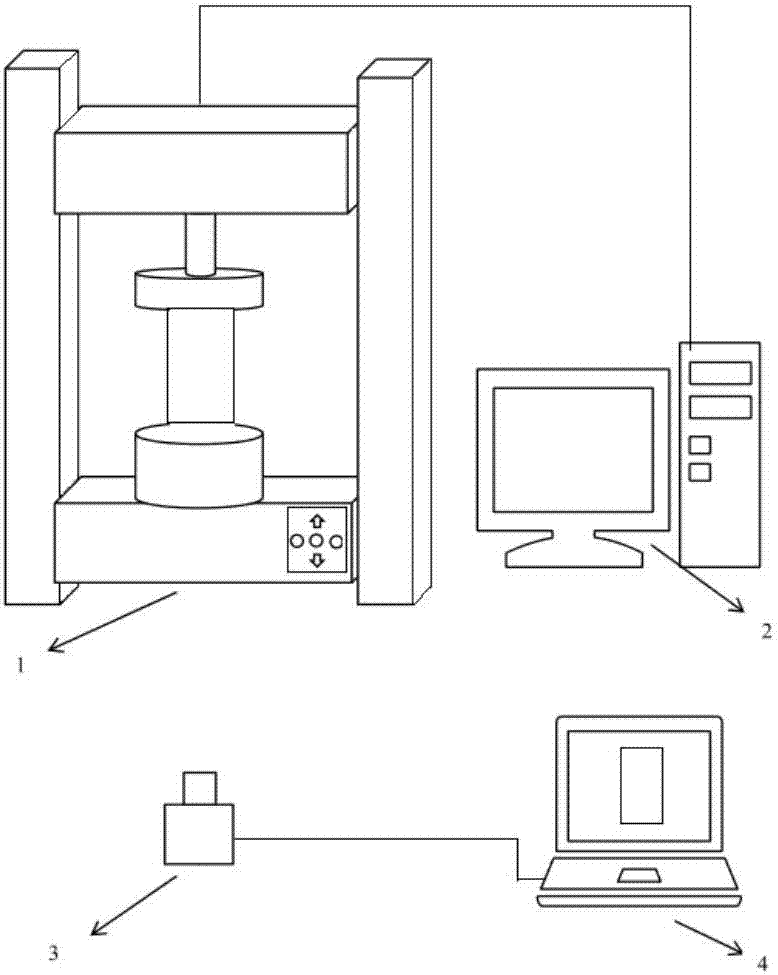

[0024] This embodiment is realized in the rock compression failure prediction device, the main structure of the device includes: universal testing machine 1, universal testing control system 2, CCD industrial camera 3 and computer 4, universal testing machine 1 is used for compressing sandstone samples, The universal testing control system 2 is connected with the universal testing machine 1 to control the start and stop of the universal testing machine 1. There is a CCD industrial camera 3 in front of the universal testing machine 1 to test the universal testing machine 1 in compressed sandstone. The sample process is used for image acquisition, and the CCD industrial camera 3 is connected with the computer 4 to save the collected images.

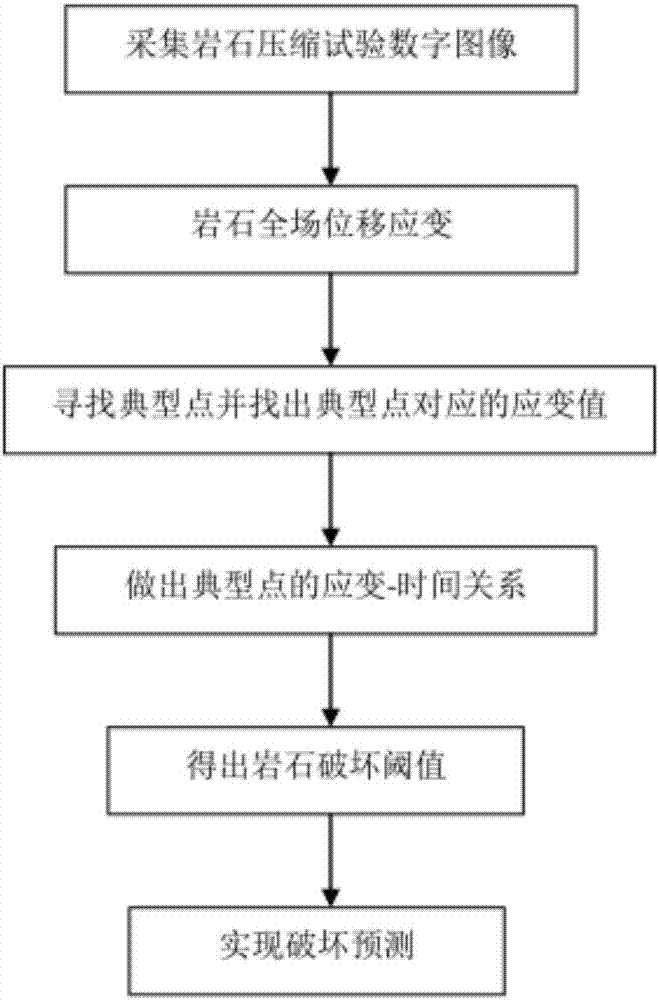

[0025] The rock compression failure prediction device is used to predict rock compression failure. The specific test method is carried out according to the following steps:

[0026] 1. Select the size of the sandstone sample as a cylinder w...

Embodiment 2

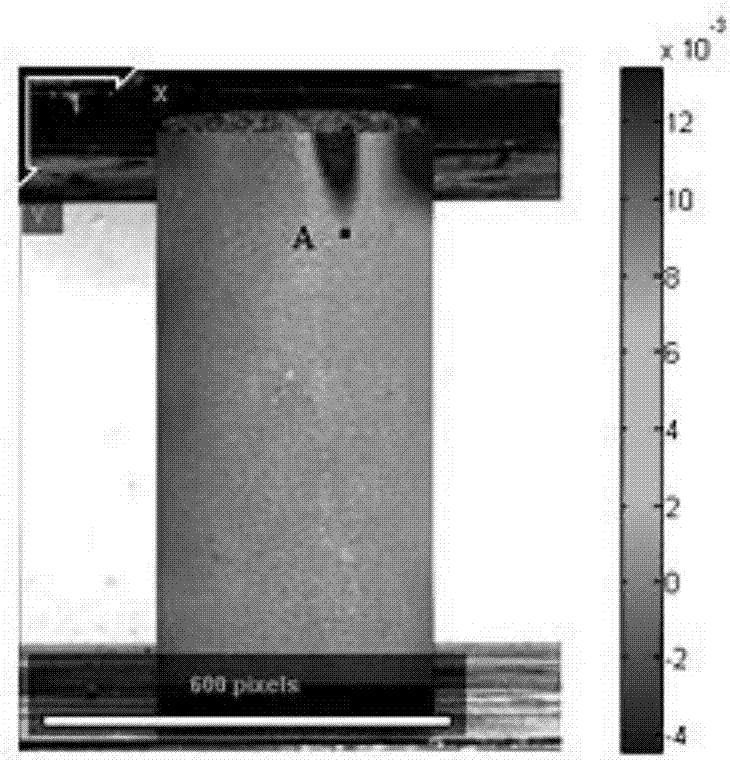

[0037] Carry out sandstone failure prediction to A point of sandstone sample by the method described in embodiment 1, test result is as follows image 3 and Figure 4 As shown, when the loading speed is 0.1MPa / s, the strain value does not change much before 131s, and shows an approximately linear increase; the strain value has a relatively large change during the period from 0.0044 at 131s to 0.011 at 131.5s, and the strain When the curve has an inflection point, it is predicted that the failure time at point A is about 131s, and the strain value of point A failure is approximately 0.011.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com