Cnt purification method using fluidized bed reactor

A fluidized bed reactor and purification method technology, applied in the field of carbon nanotube purification, can solve the problems of reducing product production, environmental pollution, waste acid treatment, etc., and achieve the effect of shortening the time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

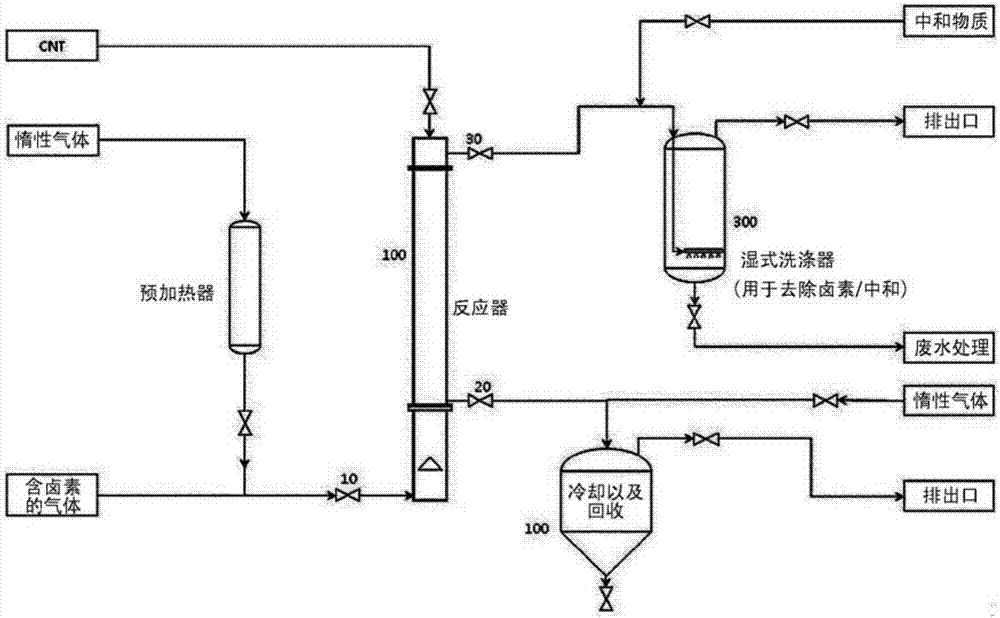

Method used

Image

Examples

preparation example 1

[0076]Preparation Example 1: Preparation of Carbon Nanotubes (CNTs)

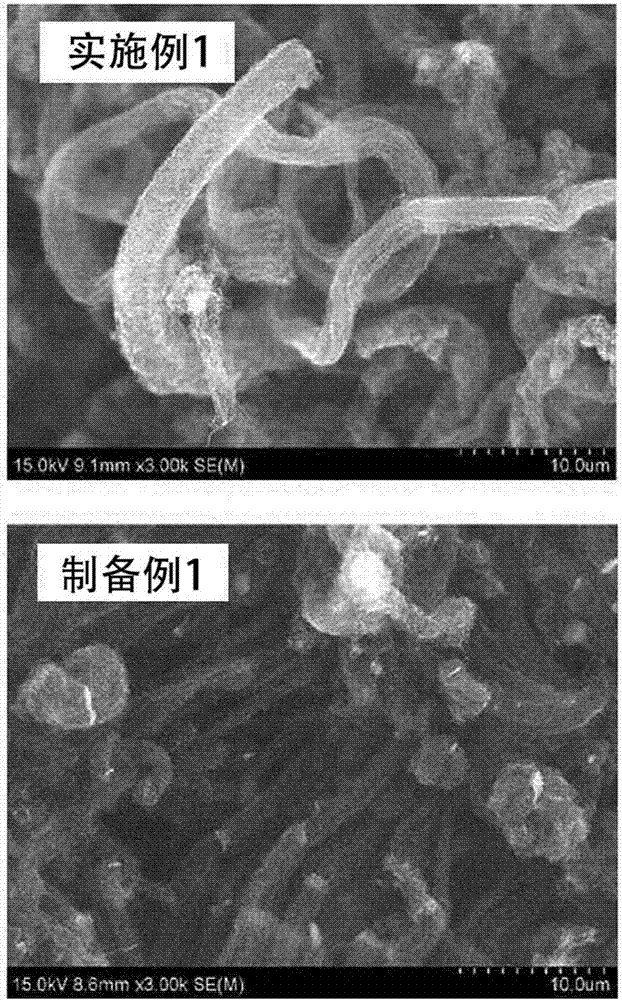

[0077] Carbon nanotube synthesis experiments were carried out using metal catalysts containing Co / Fe / Mo / V / Al for CNT synthesis in a laboratory-scale fluidized bed reactor. Specifically, the CNT synthesis catalyst and CNT prepared in the above process are mixed and installed in the middle of a quartz tube with an inner diameter of 55 mm, then, under a nitrogen atmosphere, the temperature is raised to 700 ° C and the temperature is maintained, and nitrogen and Ethylene and hydrogen were respectively flowed in at a flow rate of 900 sccm and synthesized for 2 hours to synthesize entangled (non-bundled) carbon nanotube aggregates. Photographs of the fabricated CNTs are shown in figure 2 And in the preparation example 1.

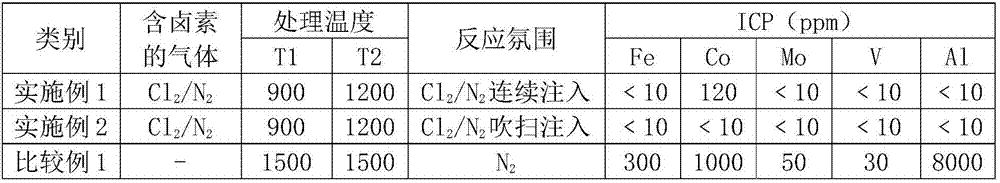

Embodiment 1 to 2 and comparative example 1

[0078] Examples 1 to 2 and Comparative Example 1: Purification of carbon nanotubes

Embodiment 1

[0080] 20 g of the carbon nanotubes prepared in Preparation Example 1 were placed in a fluidized bed reactor. Inject N at a flow rate of 1000 sccm 2 , and the internal temperature of the reactor was raised to 900 °C. Then, the Cl 2 and N 2 A 1:1 ratio of halogen-containing gas was supplied at a flow rate of 1000 sccm for 30 minutes.

[0081] Then, after injecting only N 2 Afterwards, the sample was transferred to the second high-temperature reactor at 1200 °C, followed by N 2 The flow condition of the gas atmosphere was maintained for 30 minutes and then cooled. For photos of CNTs that have passed through this process figure 2 A photographic representation of Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com