A Straw Feed High Density Compression Molding Machine and Its Hydraulic Control System

A straw feed, high-density technology, applied in the direction of mechanical equipment, agricultural machinery and implements, fluid pressure actuators, etc., can solve the problems of high inventory and logistics costs, a large amount of straw feed, and large differences in the moisture content of straw bales. It achieves the effects of wide application range, convenient automatic operation and low dry matter loss rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

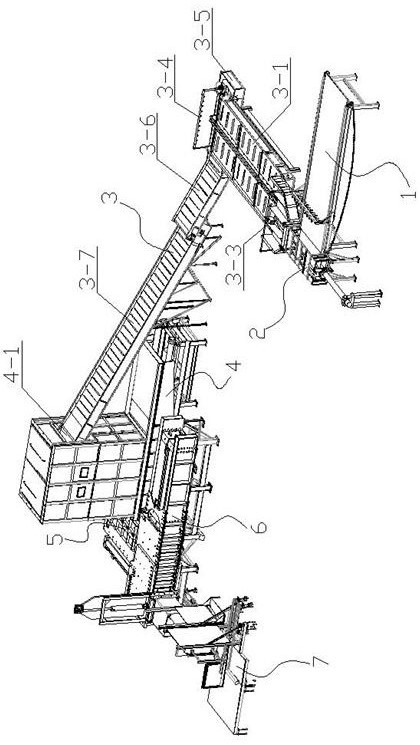

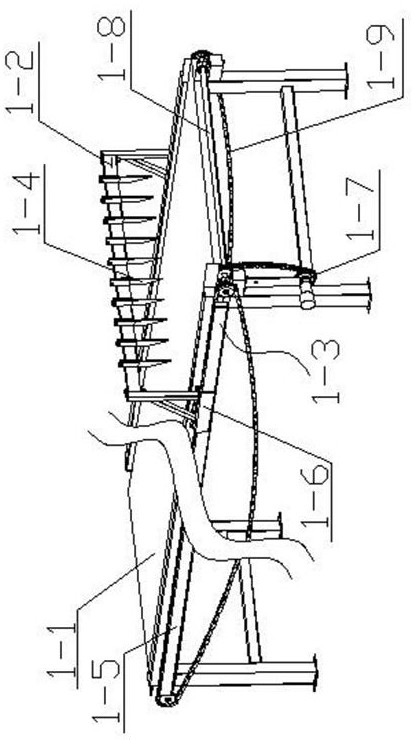

[0044] Such as Figure 1 to Figure 6 As shown, a straw feed high-density compression molding machine includes a collecting and supplying device 1, a cutting and diverting device 2, a conveying device 3, a preliminary forming device 4, a pre-pressing device 5, a main pressing device 6 and a stacking device 7;

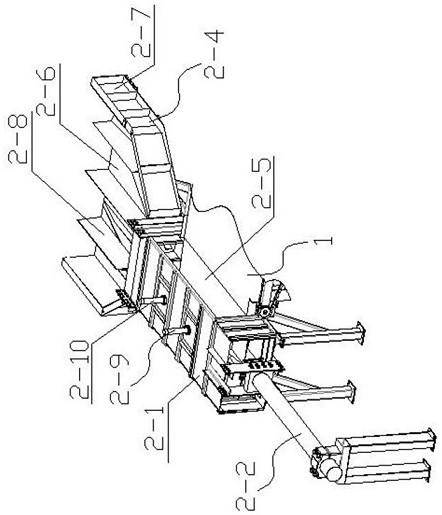

[0045] The cutting and distributing device 2 comprises a cutting chamber 2-1, a propulsion mechanism 2-2, a cutter and a distributing mechanism 2-4. One end of the cutting chamber 2-1 is provided with a propulsion mechanism 2-2, and the other end is provided with a distributing mechanism 2-4. The end of the mechanism 2-4 is connected to the conveying device 3, the side of the cutting chamber 2-1 is provided with a cutting chamber material inlet 2-5 connected to the tail end of the supply collecting device 1, and a cutting knife is also pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com