High-strength steel having superior brittle crack arrestability, and production method therefor

A technology of crack propagation and manufacturing method, which is applied in the field of high-strength steel and its manufacturing, can solve the problems of reduced productivity, can not be said to solve the problems of brittle crack growth resistance, and is not suitable for commercial applications, so as to achieve high yield strength and brittle resistance Excellent crack growth effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

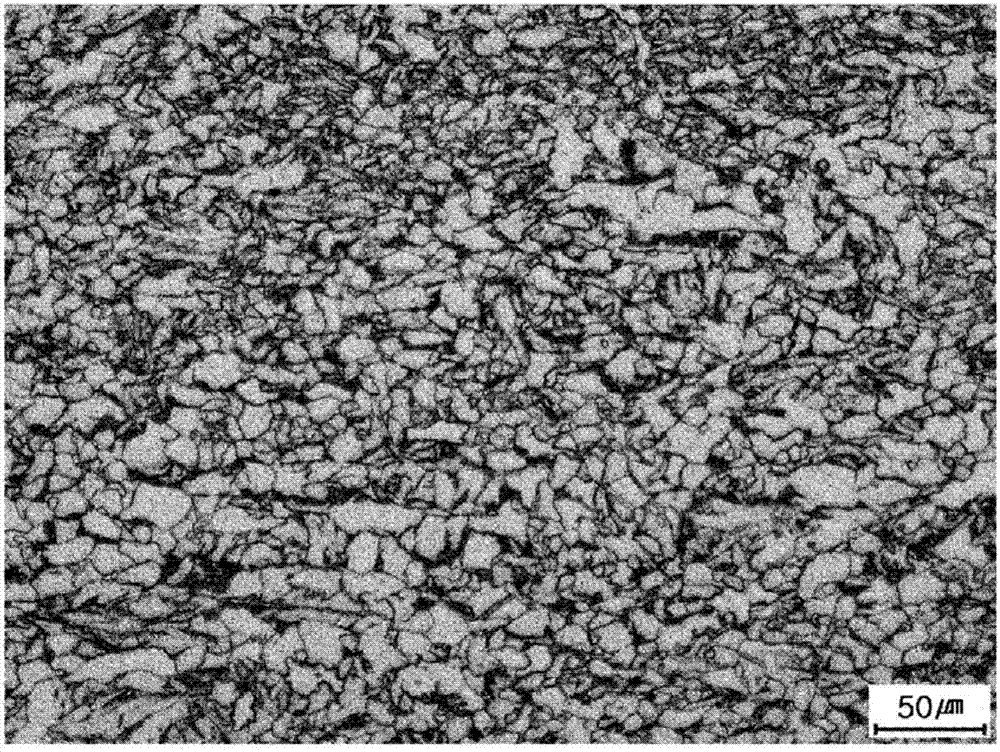

Image

Examples

Embodiment 1

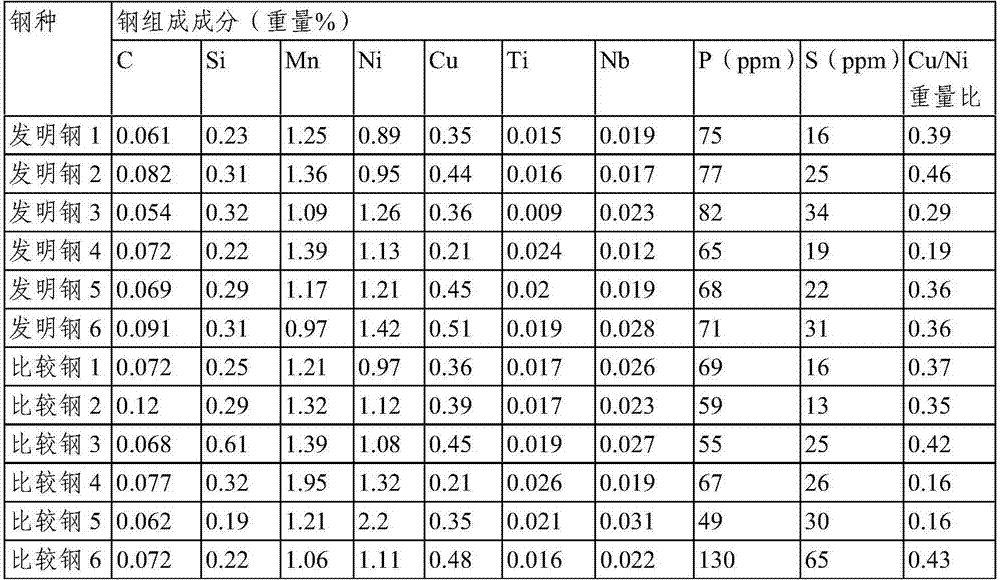

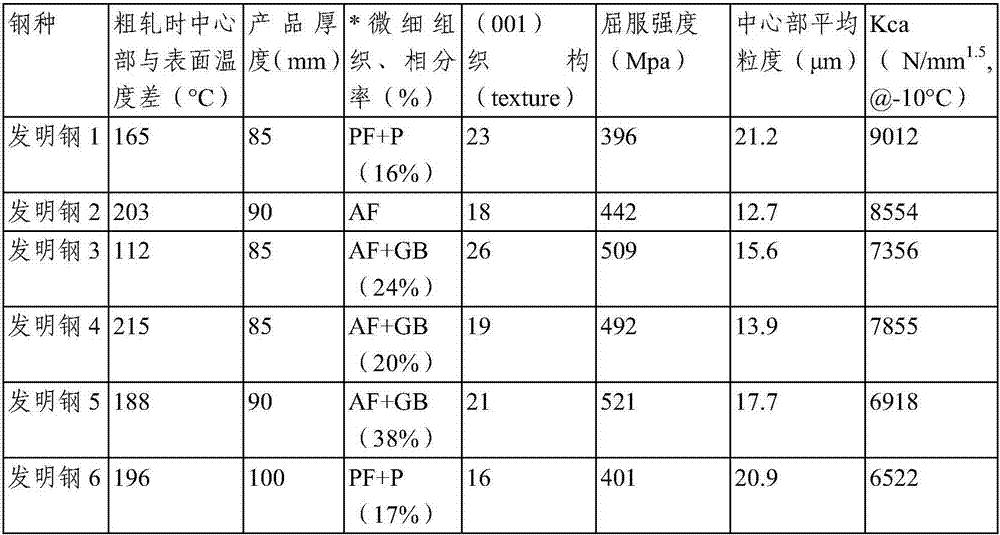

[0132] After reheating at a temperature of 1050°C, a steel slab having a thickness of 400 mm and having the composition shown in Table 1 below was subjected to rough rolling at a temperature of 1020°C to produce rods. The average temperature difference between the surface and center of the slab during rough rolling is shown in Table 2 below. The cumulative reduction ratio was 50%, and the same reduction ratio was used.

[0133] The average temperature difference between the center and the surface during rough rolling in Table 2 represents the actual measured surface temperature of the slab or bar before rough rolling and the center calculated by considering the moisture content sprayed onto the bar and the thickness of the slab before rough rolling. The temperature difference is the result of measuring the temperature difference of each rough rolling pass and calculating the overall average value.

[0134] The thickness of the rough-rolled bar is 180 mm, and the grain size aft...

Embodiment 2

[0154] As shown in Table 3, except that the Cu / Ni weight ratio of the steel slab was changed, steel plates were produced with the same composition and production conditions as Invention Steel 2 in Example 1, and the surface of the produced steel plates were investigated. properties, and the results are shown in Table 3.

[0155] The surface properties of the steel sheets in Table 3 below were measured to determine whether or not star cracks occurred in the surface portion due to hot shortness.

[0156] table 3

[0157]

[0158] As shown in Table 3, it can be seen that when the Cu / Ni weight ratio is properly controlled, the surface characteristics of the steel sheet are improved.

Embodiment 3

[0160] As shown in FIG. 4 , except that the grain size (μm) after rough rolling and before finish rolling was changed, steel sheets were produced with the same composition and production conditions as Invention Steel 1 in Example 1, and the produced steel sheets were investigated. Table 4 shows the average characteristics of the grain size at the center of the steel sheet and the results.

[0161] Table 4

[0162] steel type

[0163] As shown in Table 4, it can be seen that the smaller the grain size of the central portion of the rod after rough rolling becomes, the finer the average grain size of the central portion becomes, and thus it is expected that the resistance to brittle crack growth is improved.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com