Self-propelled peanut harvester

A peanut harvester and self-propelled technology, which is applied to digging harvesters, harvesters, loaders, etc., can solve the problems of poor harvesting effect, low harvesting efficiency, and large labor load, so as to achieve good fruit picking effect and improve economic efficiency. Benefits, the effect of reducing the broken rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with accompanying drawing:

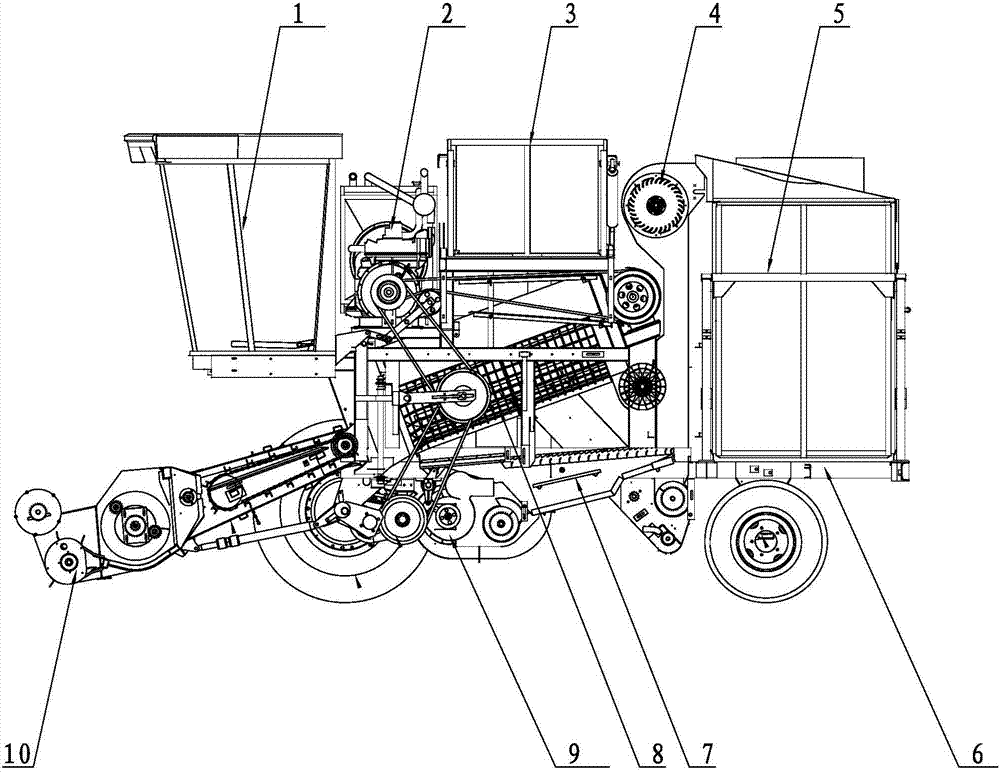

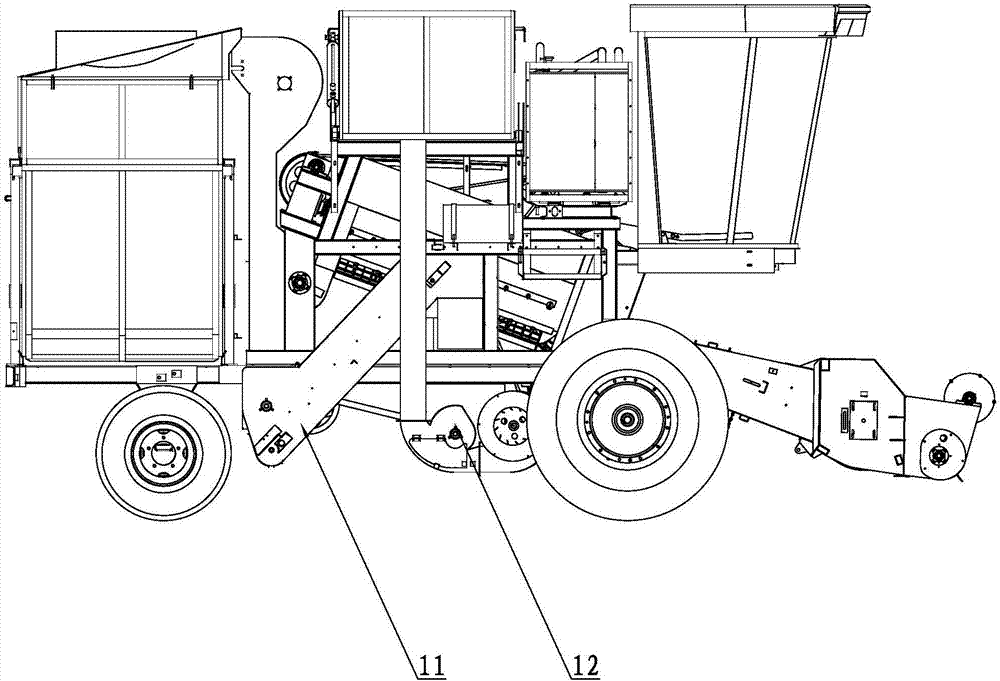

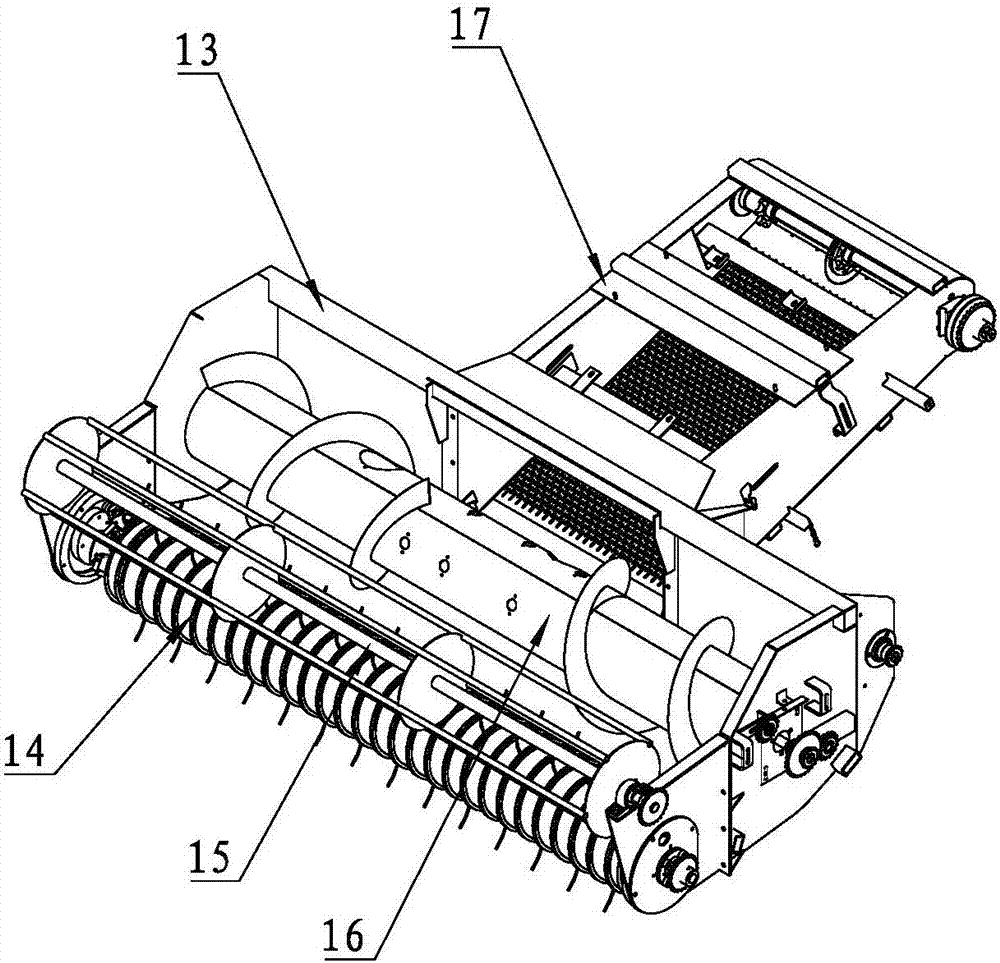

[0034] Such as Figure 1 to Figure 11As shown, the self-propelled peanut harvester of the present invention includes a working chassis assembly, and the working chassis assembly includes a power system 2, a walking chassis system, and a driving control system 1, and the walking chassis system includes a frame 6, and the frame 6 The harvesting work assembly is arranged on the top, and the harvesting work assembly includes a peanut picking and harvesting device 10, a fruit picking drum 8 and a straw chopping and conveying collection device 4 arranged in sequence from front to back. A cleaning device 9 is arranged below the drum 8, a fruit conveyor 12 is arranged below the cleaning device 9, and a fruit box 3 is correspondingly set at the outlet end of the fruit conveyor 12, and the fruit box 3 is positioned above the fruit picking drum 8 of the peanut harvester, and the clean...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com