Method for processing Chinese chestnut aroma tea

A processing method and technology of fragrant tea, applied in the processing field of chestnut-flavored tea, can solve the problems affecting the quality of Guizhou chestnut-flavored flat green tea, unsuitable temperature control, complex production process, etc., and achieve comprehensive quality, convenient operation and low cost. cheap effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

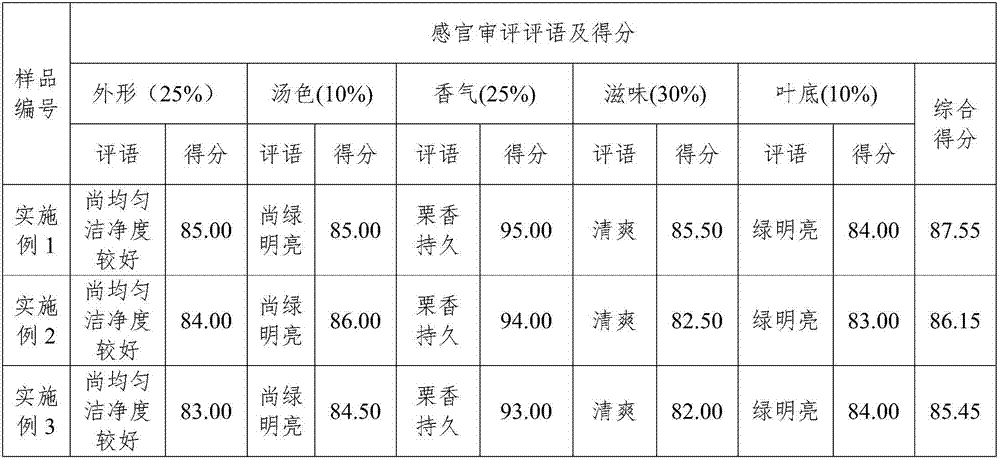

Examples

Embodiment 1

[0022] The processing method of chestnut-flavored tea of the present invention comprises the following steps:

[0023] (1) Withering: Pick fresh leaves with one bud and one leaf or one bud and two leaves, uniform in size, spread evenly and thinly in the withering tank, the thickness of the spread is 3-5cm, the spreading time is 5h, and the interval is 0.5, flipping once, And knead once by hand, so that the water content of the green tea is 70-80%, and the fresh leaves are wilting;

[0024] (2) Finishing: Use a drum-type greening machine to finish the withered green tea. The finishing temperature is 220-230° C. and the time is 1 minute. Cool the tea leaves that have been finished for the first time at room temperature to regain moisture, and then perform the second finishing. The killing temperature is 120-130°C, and the time is 2 minutes. When the leaf color changes from green to dark green, the leaf quality is soft and sticky, the grass smell disappears, and the tea aroma i...

Embodiment 2

[0032] The processing method of chestnut-flavored tea of the present invention comprises the following steps:

[0033] (1) Withering: The fresh leaves picked as one bud and one leaf or one bud and two leaves are evenly sized and spread evenly and thinly in the withering tank with a thickness of 3-5cm. The spreading time is 8 hours, and the leaves are turned once every 1 hour. Knead once by hand to make the tea green water content 80-85%, and the fresh leaves are wilting;

[0034] (2) Fixing: Use a drum-type fixing machine to fix the withered green tea. The fixing temperature is 240-260°C, and the time is 0.5min. Cool the tea leaves that have been fixed for the first time to moisture at room temperature, and then perform the second fixing , the finishing temperature is 130-140°C, the time is 3min, until the leaf color changes from green to dark green, the leaves are soft and sticky, the grass gas disappears, and when the tea fragrance is revealed, the finishing is completed, ...

Embodiment 3

[0042] The processing method of chestnut-flavored tea of the present invention comprises the following steps:

[0043] (1) Withering: Pick fresh leaves with one bud and one leaf or one bud and two leaves, uniform in size, spread evenly and thinly in the withering tank, the thickness of the spreading is 2-5cm, the spreading time is 3 hours, and it is turned once every 0.5 hours , and knead once by hand, so that the water content of the green tea is 70-75%, and the fresh leaves are wilting;

[0044] (2) Finishing: Use a drum-type greening machine to finish the withered green tea. The finishing temperature is 220-230° C. and the time is 2 minutes. Cool the tea leaves that have been finished for the first time at room temperature to regain moisture, and then perform the second finishing. The killing temperature is 120-130°C, and the time is 2 minutes. When the leaf color changes from green to dark green, the leaf quality is soft and sticky, the grass smell disappears, and the te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com