Method for simulating processing process of stir-fried medicinal materials

A processing technology and a technology for medicinal materials, which are applied in the field of simulating the processing technology of fried medicinal materials, can solve the problems of high frying temperature, can not well achieve processing to reduce toxicity, increase efficiency, and take a long time, and achieve accurate control of heating temperature, Accurately predict frying temperature and time, cost saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

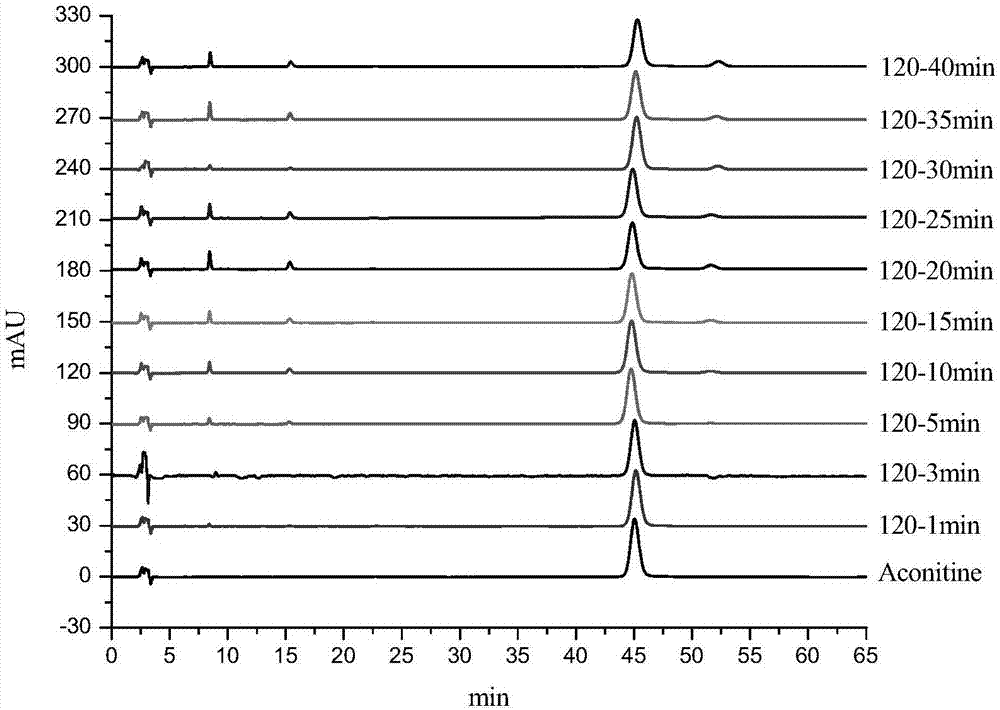

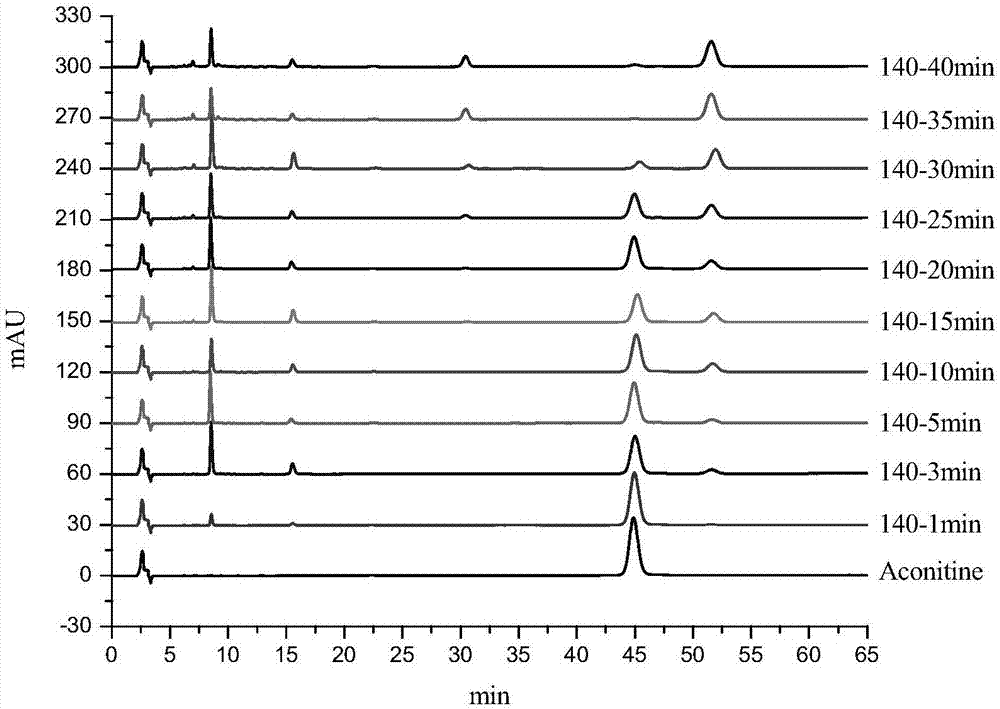

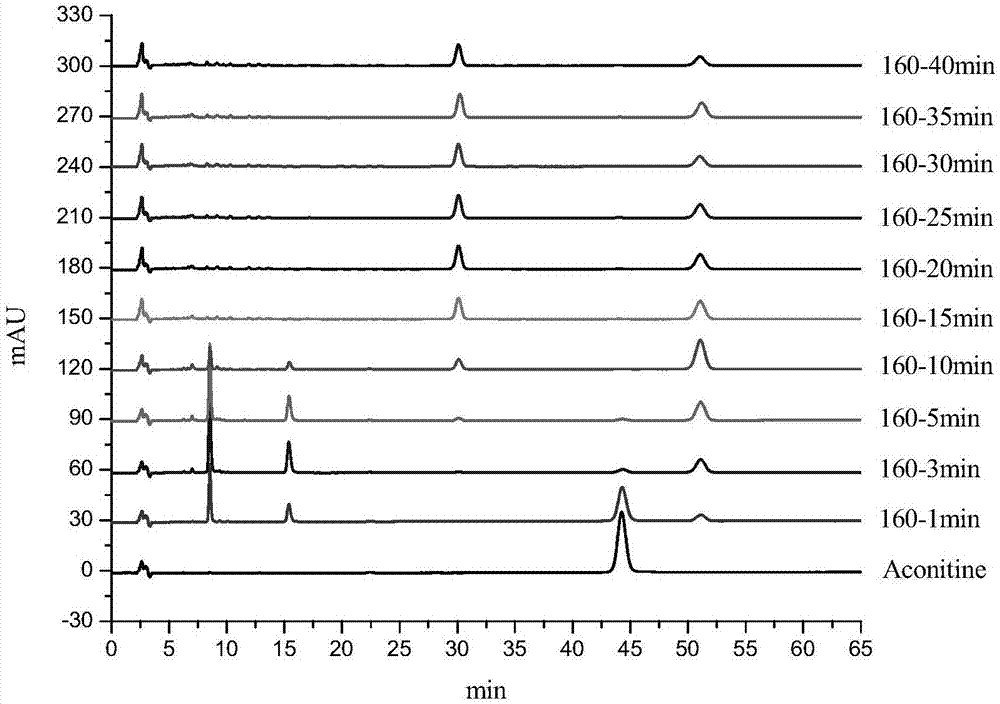

[0034] Example 1 Study on Process Parameters of Aconitine Oil Bath Simulating Iron Rod and Hammer Sand Stir-fry

[0035] Taking aconitine, the main toxic component in the iron rod hammer, as the research object, the oil bath was used to simulate the sand frying process, and the conversion process was analyzed by HPLC; the content was determined by the external standard one-point method; It provides a basis for the quantitative standard research of sand frying process.

[0036] 1 Instruments and reagents

[0037] Agilent 1260 high performance liquid chromatograph, UV detector, Agilent Chemastation chromatographic workstation; CPA2250 electronic analytical balance (Germany Sartorius company); ULUP-I-10T Youpu ultrapure water machine (Chengdu Ultrapure Technology Co., Ltd.); HH- SJ heat-collecting magnetic stirrer (Jintan Chengdong Xinrui Instrument Factory); aconitine (Chengdu Master Biological Technology Co., Ltd., batch number MUST-15121111); acetonitrile is chromatographical...

Embodiment 2

[0052] Example 2 Using 3-acetylaconitine oil bath to simulate iron bar hammer sand frying process parameters

[0053] Taking 3-acetylaconitine, the main toxic component in iron bar hammer, as the research object, the oil bath was used to simulate the sand frying process, and the conversion process was analyzed by HPLC; the content was determined by the external standard one-point method; It provides a basis for the research on the quantitative standard of the hammer sand frying process.

[0054] 1 Instruments and reagents

[0055] Agilent 1260 high performance liquid chromatograph, UV detector, Agilent Chemastation chromatographic workstation; CPA2250 electronic analytical balance (Germany Sartorius company); ULUP-I-10T Youpu ultrapure water machine (Chengdu Ultrapure Technology Co., Ltd.); HH- SJ heat-collecting magnetic stirrer (Jintan Chengdong Xinrui Instrument Factory); 3-acetylaconitine (self-made, area normalization method, content> 98%); Methanol is chromatographicall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com