Mould fixing structure for backward extrusion and backward extrusion method

A technology of reverse extrusion and fixed structure, applied in the direction of metal extrusion dies, etc., can solve the problems of increased production cost, long non-extrusion time, complicated extrusion process, etc., to improve production efficiency, reduce production cost, shorten The effect of unsqueezed time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

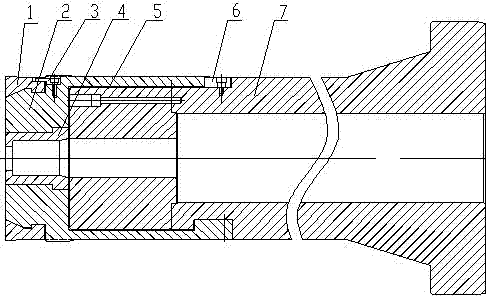

[0021] This embodiment provides a mold fixing structure for reverse extrusion, comprising a mold 4, a reverse extrusion die shaft 7, the reverse extrusion die shaft 7 is installed on a movable mold base, and the mold 4 is covered with a mold Cover 2, the mold cover 2 is connected with the reverse extrusion die shaft 7, a mold support 5 is provided between the mold 4 and the reverse extrusion die shaft 7, and the mold support 5 is arranged in the die cover 2 and It is fixedly connected with the reverse extrusion die shaft 7, and the mold 4, the die support 5 and the reverse extrusion die shaft 7 are all coaxial.

[0022] Using process: Fix the mold 4 on the reverse extrusion mold shaft 7 through the mold support 5 and the mold sleeve 2, and then send the ingot and the mold 4 to the extrusion center by the mobile mold base, and start extrusion. Only need to take and deliver the ingot until all the ingots are extruded and taken out of the mold 4 .

[0023] Fixing the mold 4 simp...

Embodiment 2

[0025] On the basis of embodiment 1, this embodiment provides a kind of figure 1 In the shown die fixing structure for reverse extrusion, the mold sleeve 2 is provided with an expansion ring 1 at one end, and the other end is connected with the reverse extrusion die shaft 7 .

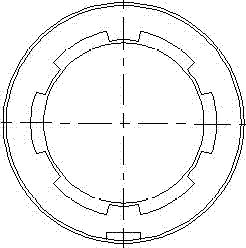

[0026] During the extrusion process, the expansion ring 1 protruding into the extrusion cylinder is expanded by the extrusion force, and the contact with the inner wall of the extrusion cylinder prevents the aluminum billet from entering the reverse extrusion die shaft 7 and extruding The gap between the cylinders is convenient for later cleaning. The structure of the expansion ring 1 is as figure 2 shown.

[0027] In this embodiment, the mold support 5 is a hollow structure with assembly holes arranged in the circumferential direction, the inner diameter of the mold support 5 is equal to the inner diameter of the mold 4 , and the outer diameter is larger than the outer diameter of the mold 4 . The ...

Embodiment 3

[0031] On the basis of Embodiment 1, this embodiment provides a mold fixing structure for reverse extrusion, and a radial gap is reserved between the mold support 5 and the mold sleeve 2 .

[0032] There is a gap reserved in the radial direction between the mold support 5 and the mold sleeve 2, which can ensure that the expansion ring 1, the mold sleeve 2 and the mold 4 can be flexibly aligned when they extend into the extrusion cylinder, and ensure that the extrusion rod, extrusion cylinder, mold 4 and Concentricity of reverse extrusion die axis 7.

[0033] Such as figure 1 As shown, the inner diameter of the counter-extrusion die shaft 7 is larger than the inner diameter of the die support 5 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com