Automatic uniform and constant-speed feeding bin

An automatic technology for feeding bins, applied in the field of feeding bins, can solve the problems of frequent manual feeding, etc., and achieve the effect of solving frequent work, improving the yield rate, and not being affected by moisture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

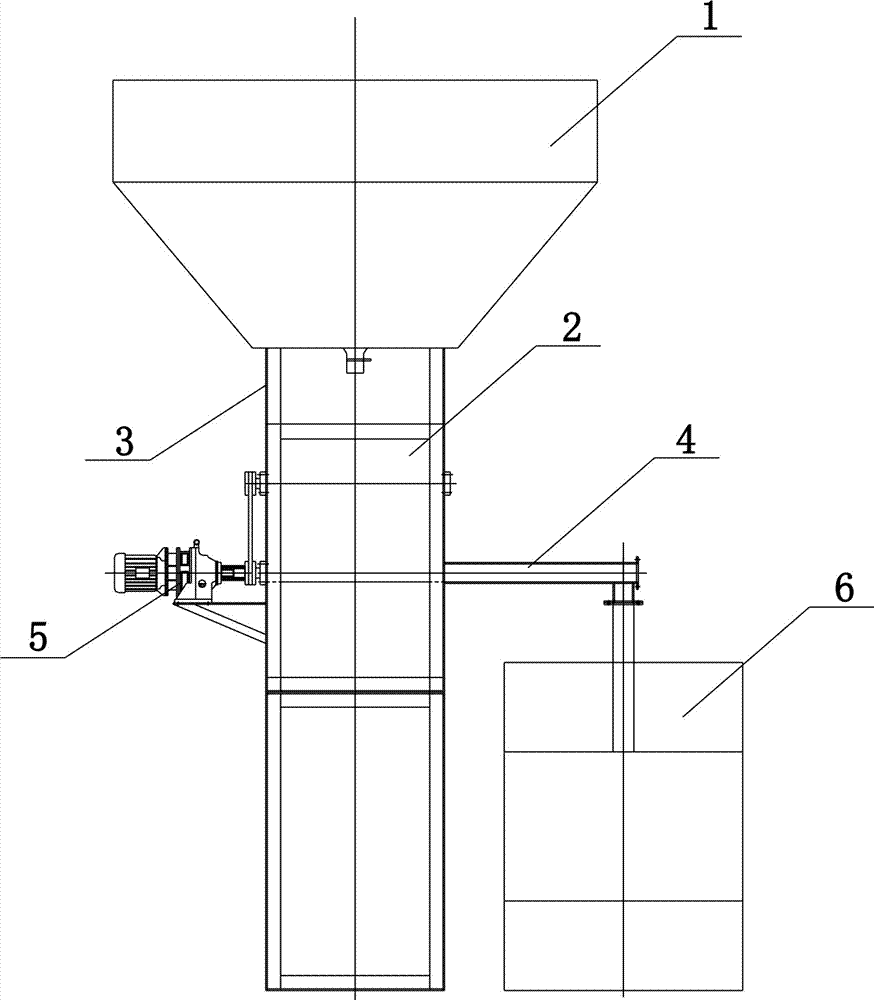

[0016] Such as figure 1 As shown, the automatic screed and uniform feed silo includes a large hopper 1, a small hopper 2. The upper part of the small hopper 2 is equipped with a large hopper 1 through a carbon steel bracket 3, and the bottom of the small hopper 2 is provided with a U-shaped groove 4, U A spiral feeding body is arranged in the groove 4, a sprocket is installed on the spiral feeding body, and the sprocket is connected to the reducer 5 through a chain. The screw feeder body is driven by the speed reducer 5 to drive the chain, and the chain drives the shaft head sprocket on the screw feeder body to rotate and feed. A heating furnace 6 is placed under the U-shaped groove 4.

[0017] The upper part of the large hopper 1 is a square box body, and the lower part is a conical box body. The top of the large hopper 1 is provided with a box cover, and the bottom of the large hopper 1 is provided with a circular tube discharge port. The whole hopper 1 is made of PVC materia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com