Truck loading robot and truck loading method thereof

A technology of robots and trucks, applied in the direction of conveyor objects, transportation and packaging, loading/unloading, etc., can solve the problems of difficult to effectively guarantee the working stability and working accuracy, difficult to meet the use requirements, large use restrictions, etc., to achieve the degree of automation High, low use requirements, and the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

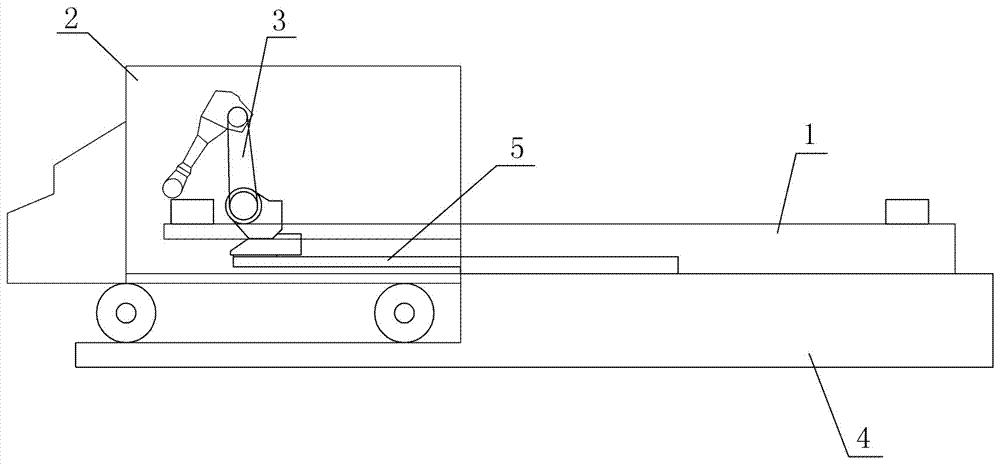

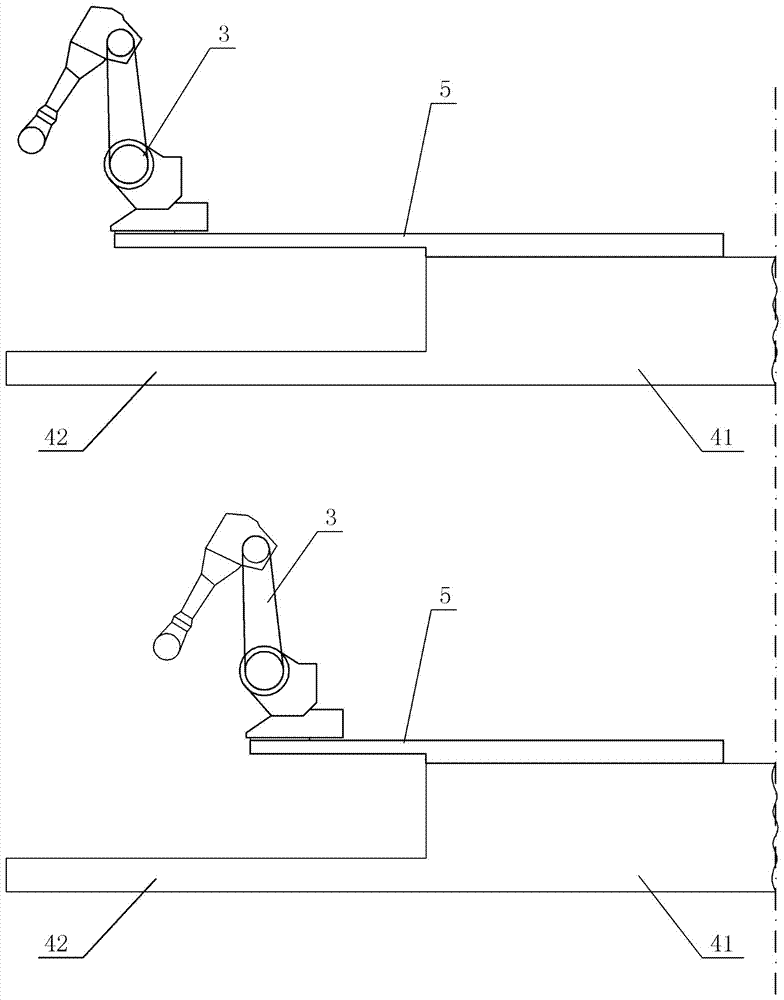

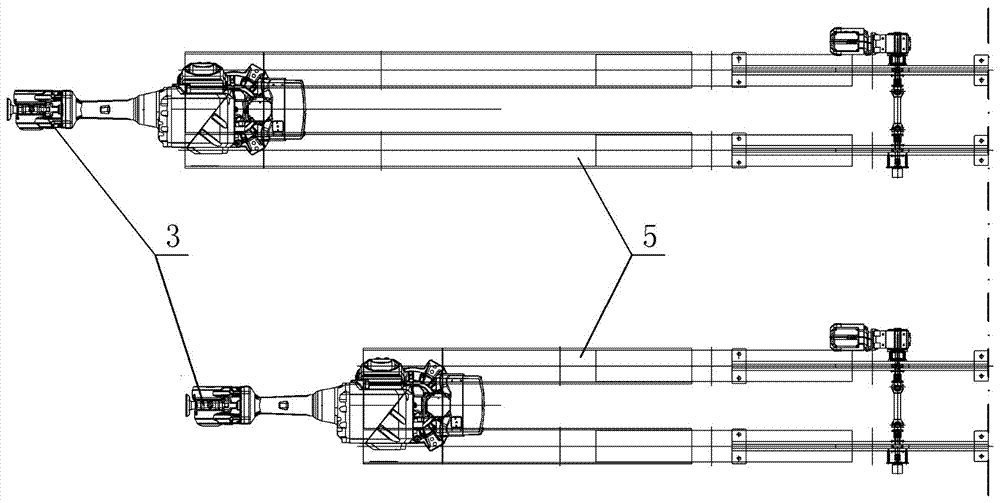

[0018] A loading robot, including a conveying line 1 for transporting materials, a manipulator 3 for grabbing the materials on the conveying line to be stacked in a truck 2, a fixed base 4 and a retractable telescopic device 5, the base is set on Outside the two sides or the rear side of the truck parking position, the two ends of the telescopic device along the telescopic direction are the fixed end and the mobile end respectively. One side of the telescoping device. The base is fixed. When loading, the truck moves to a parking position close to the base and opens the rear or side door of the container; then, the telescopic device and the conveyor line work, and the telescopic device drives the manipulator to move to the side of the container. Inside or on the side, at the same time, the conveyor line transports the material to the side of the manipulator; then, the manipulator moves, first removes the material from the conveying line, and then puts the material in the truck....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com