Bastose blended spunlace non-woven material used for facial masks and dry and wet tissues and preparation method of material

A technology of non-woven materials, dry wipes, applied in the direction of non-woven fabrics, textiles and papermaking, etc., to achieve the effects of excellent physical properties, good moisture absorption and moisturizing properties, and good natural antibacterial properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

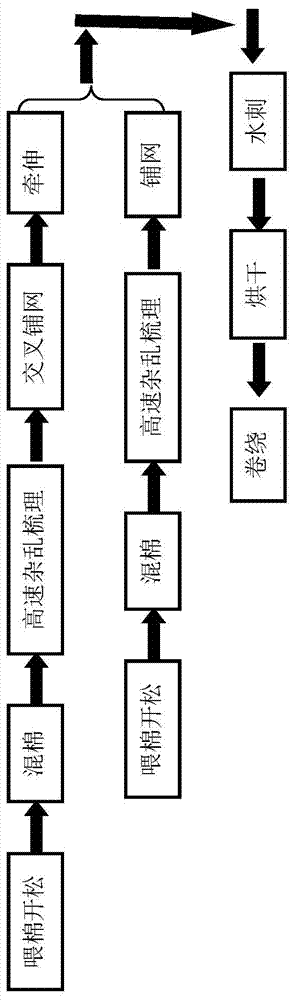

[0052] Such as figure 1 As shown, the preparation method of the hemp fiber blended spunlace nonwoven material for facial masks and dry wet wipes in this embodiment includes the following steps:

[0053] (1) Preparation of raw materials: the selected fibers and their mass percentages are as follows:

[0054] Hemp fiber 30%;

[0055] Lyocell fiber 30%;

[0056] Modal fiber 20%;

[0057] Bamboo Daier fiber 10%;

[0058] 10% raw cotton fiber.

[0059] (2) Feeding, opening and blending: the hemp fiber and combined fiber are sent to the opening machine manually for opening, so that the fiber mass and the large cotton mass are separated, mixed and fully opened. After rough opening, the fibers are transported to the mixing box by air flow, and the fibers are opened and mixed for the second time by the wind force of the fan.

[0060] (3) High-speed messy carding: The mixed fibers in the above-mentioned cotton mixing box are transported to a high-speed messy carding machine through airflow to comb ...

Embodiment 2

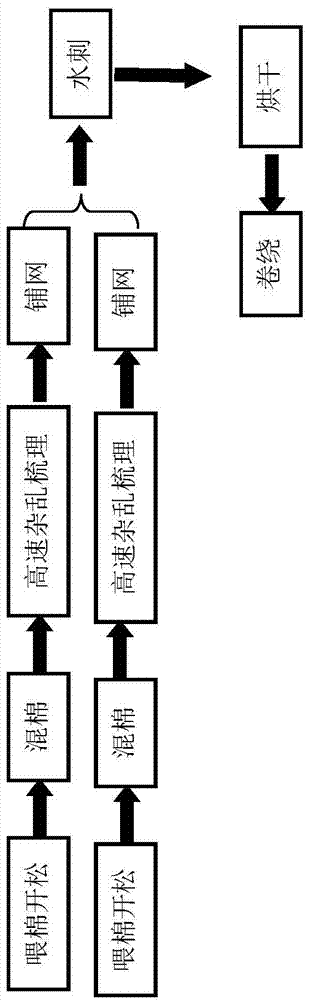

[0089] Such as figure 2 As shown, the preparation of the hemp fiber blended spunlace nonwoven material for facial masks and dry and wet wipes in this embodiment includes the following steps:

[0090] (1) Preparation of raw materials: the selected fibers and their mass percentages are as follows:

[0091] Hemp fiber 30%;

[0092] Lyocell fiber 30%;

[0093] Modal fiber 20%;

[0094] Bamboo Daier fiber 10%;

[0095] 10% raw cotton fiber.

[0096] (2) Feeding, opening and blending: the hemp fiber and combined fiber are sent to the opening machine manually for opening, so that the fiber mass and the large cotton mass are separated, mixed and fully opened. After rough opening, the fibers are transported to the mixing box by air flow, and the fibers are opened and mixed for the second time by the wind force of the fan.

[0097] (3) High-speed messy carding: The mixed fibers in the above-mentioned cotton mixing box are transported to a high-speed messy carding machine through airflow to comb th...

Embodiment 3

[0126] Such as figure 1 As shown, the preparation method of the hemp fiber blended spunlace nonwoven material for facial masks and dry and wet wipes in this embodiment is the same as that in Example 1. The selected fibers and their mass percentages are as follows:

[0127] Hemp fiber 20%,

[0128] Flax fiber 10%,

[0129] Lyocell fiber 40%,

[0130] Modal fiber 15%,

[0131] 5% of bamboo fiber,

[0132] 10% raw cotton fiber.

[0133] Product performance test:

[0134] The test process and results are as follows:

[0135] (1) Quantitative weight test

[0136] Test instrument: electronic balance, test method: GB / T24218.1-2009, test results are shown in Table 1.

[0137] Table 1 Quantitative weight test results of hemp fiber blended spunlace nonwoven materials for facial masks and wet wipes

[0138] SampleQuantitative weight (g / m 2 )

Example 332.3

[0139] (2) Thickness test

[0140] Test instrument: YG141 fabric thickness tester, test method: GB / T24218.2-2009, test results are shown in Tab...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com