A kind of functional polysaccharide antibacterial modified natural fiber and preparation method thereof

A natural fiber and functional technology, applied in the field of preparation of functional polysaccharide composite fiber, to achieve the effects of environmental friendliness, low production cost and good dyeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

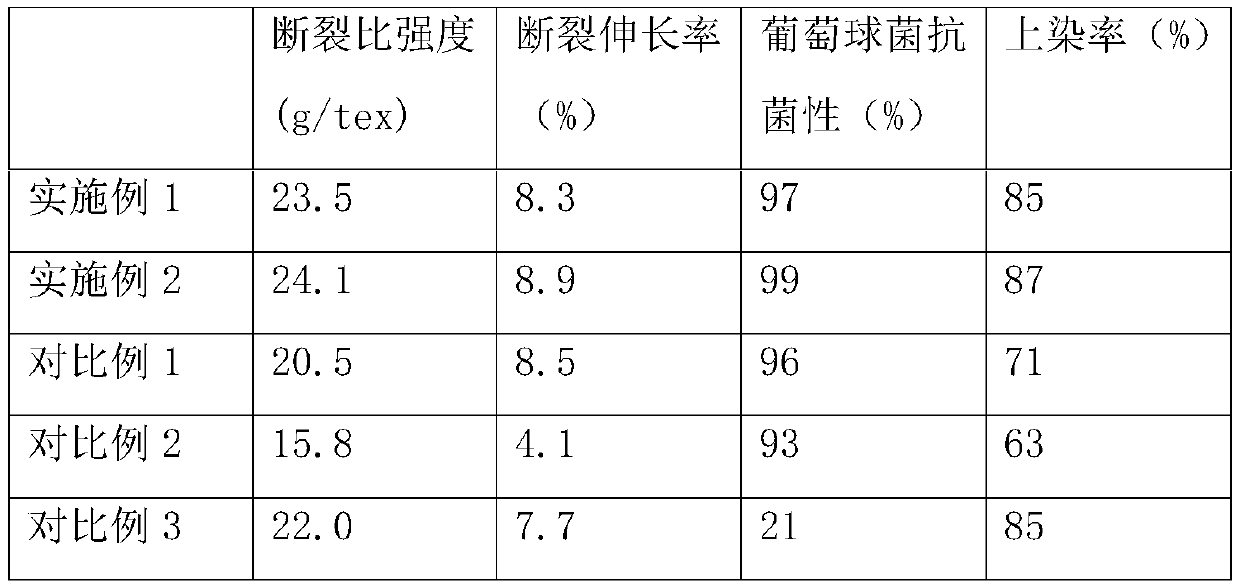

Examples

Embodiment 1

[0028] This embodiment is to carry out Radix Radix isatidis polysaccharide modification treatment on cotton fiber, comprises the following steps:

[0029] 1) Pretreating the natural fibers, soaking the fibers in sodium carbonate solution for 10 hours and then washing and drying them; 2) Using hydrogen peroxide as an oxidizing agent and using hemicellulose and acetic acid as protective agents for the pretreated fibers, wherein The amount of hemicellulose added is 0.02 times the fiber mass, and the amount of acetic acid added is 0.01 times the fiber content. Calcium titanate is used as a catalyst to carry out an oxidation reaction to oxidize the hydroxyl groups on the macromolecular chains of natural fibers into more reactive aldehydes. 3) Utilize chitosan solution to process oxidized natural fibers, the amino groups on the chitosan molecules and the C=0 on the oxidized fiber molecules directly undergo a covalent cross-linking reaction, so that chitosan and natural fibers are fir...

Embodiment 2

[0031] The present embodiment carries out ginseng polysaccharide modification treatment on cotton fiber, comprises the following steps:

[0032] 1) Pretreating the natural fibers, soaking the fibers in sodium carbonate solution for 10 hours and then washing and drying them; 2) Using hydrogen peroxide as an oxidizing agent and using hemicellulose and acetic acid as protective agents for the pretreated fibers, wherein The amount of hemicellulose added is 0.03 times the fiber mass, the amount of acetic acid added is 0.03 times the fiber content, iron titanate is used as a catalyst to carry out oxidation reaction, and the hydroxyl group on the macromolecular chain of the natural fiber is oxidized to a more reactive aldehyde 3) Utilize chitosan solution to process oxidized natural fibers, the amino groups on the chitosan molecules and the C=0 on the oxidized fiber molecules directly undergo a covalent cross-linking reaction, so that chitosan and natural fibers are firmly combined ,...

Embodiment 3

[0034] This embodiment is to carry out the modified treatment of honeysuckle polysaccharide on wool, comprising the following steps:

[0035]1) Pretreat the wool by immersing the wool in a sodium carbonate solution for 10 hours before washing and drying; 2) Using ozone as the oxidizing agent and hemicellulose and acetic acid as the protective agent for the pretreated fiber, in which the hemicellulose The amount of cellulose added is 0.01 times of the fiber mass, the amount of acetic acid added is 0.01 times of the fiber content, and barium titanate is used as a catalyst to carry out oxidation reaction to oxidize the hydroxyl groups on the macromolecular chains of natural fibers into more reactive aldehyde groups ; 3) utilize chitosan solution to process oxidized natural fiber, the amino group on the chitosan molecule and the C=0 on the oxidized fiber molecule directly take place the covalent cross-linking reaction, make chitosan and natural fiber firmly combine together, Impro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com