Tyre static unbalance improvement method based on vector calculation

A static unbalance, vector calculation technology, applied in static/dynamic balance test, measurement device, machine/structural component test, etc., can solve the problem of quantitative calculation of key factors that cannot affect the static balance of tires, poor accuracy, and cumbersome work and other problems to achieve the effect of enhancing potential value, easy operation and satisfying customer needs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to understand the above-mentioned purpose, features and advantages of the present invention more clearly, the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

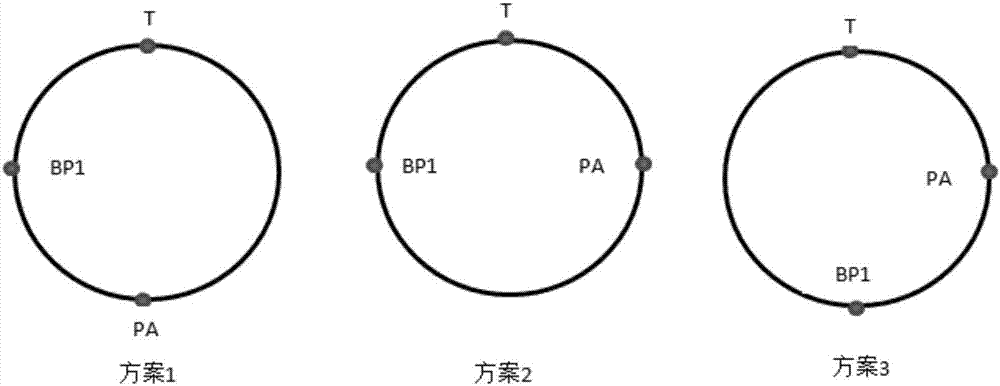

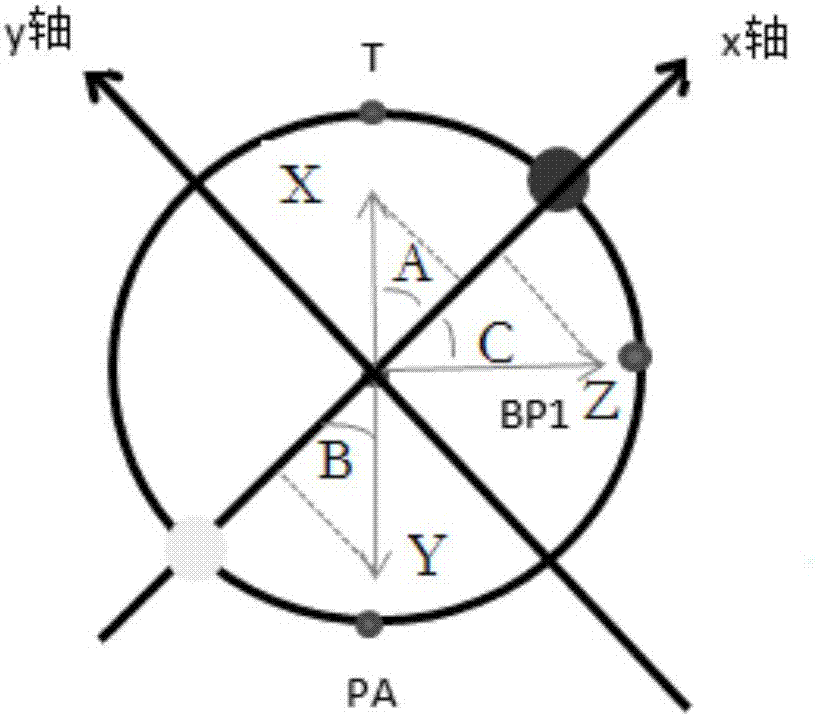

[0024] The present invention aims at the inherent static unbalance of the tire itself, and analyzes the detection results through the vector calculation method, and analyzes the three inevitable key factors affecting the static balance in the tire manufacturing process (1# cord joint, PA joint, tire Surface joints) for accurate calculations, so as to directly obtain the ideal improvement plan.

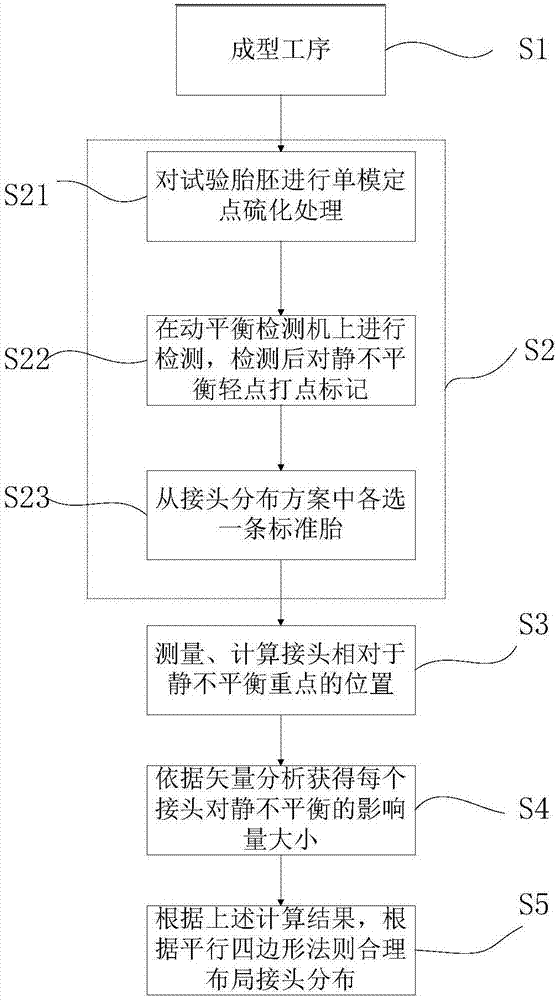

[0025] refer to figure 1 , mainly includes the following steps: step S1, forming process: pre-selecting the joint distribution scheme, and making a test embryo; step S2, vulcanization, detection and screening, including the following steps: step S21, performing single-mode fixed-point vulcanization treatment on the test embryo to Reduce the variabl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com