Method for optimizing alloy extrusion process

An alloy and process technology, applied in the field of optimization of alloy extrusion process and hot extrusion process, can solve problems such as failure to use equipment, poor performance of extrusion products, waste of resources, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

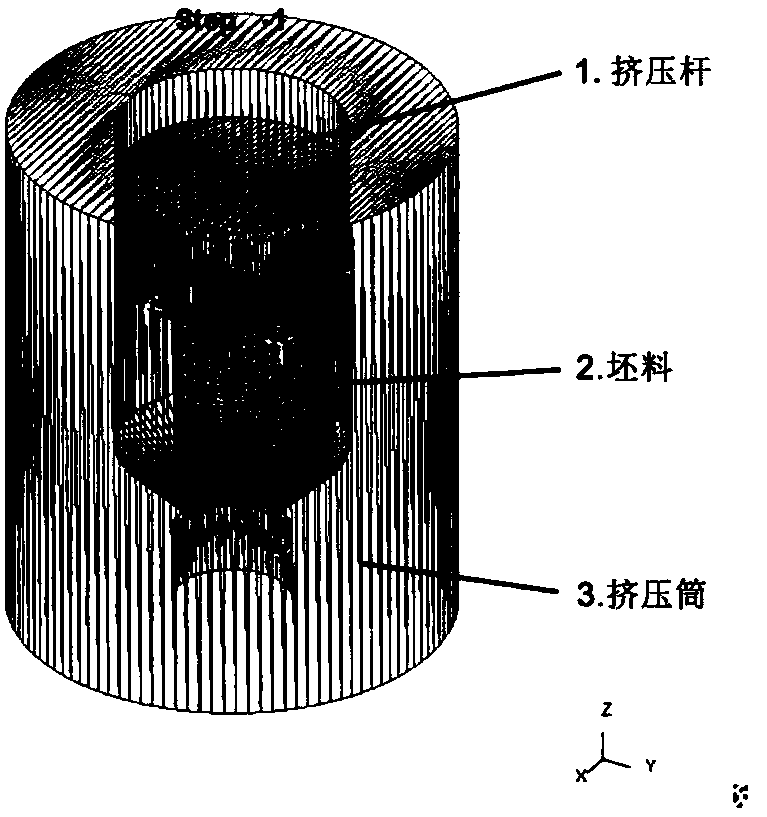

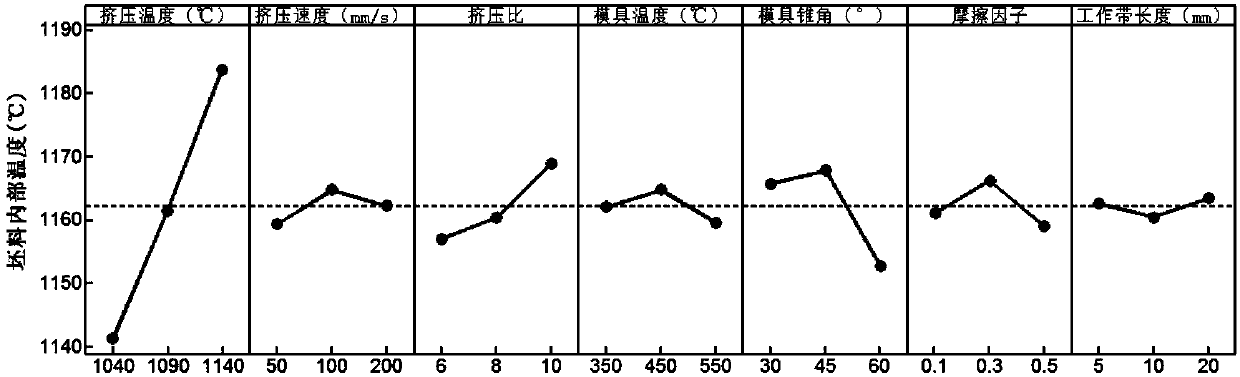

[0076] Taking nickel-based superalloy as an example, follow the steps below

[0077] Step 1 Establish the constitutive equation of the alloy to be extruded (nickel-based superalloy)

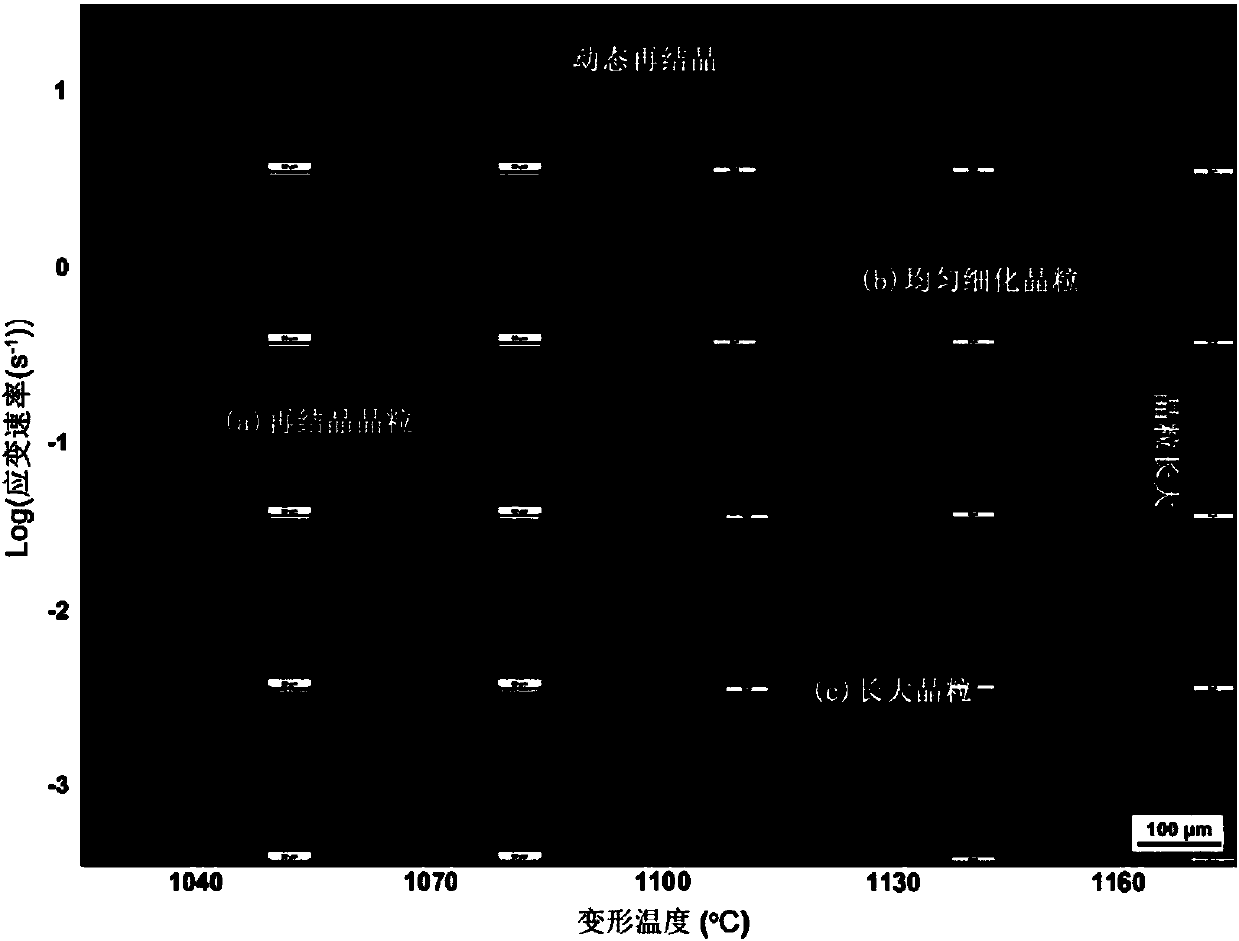

[0078] Select 5 values between 1040-1160°C; these five values are 1040°C, 1070°C, 1100°C, 1130°C, 1160°C;

[0079] At a strain rate of 0.0001-100s -1 Select 5 point values between; 5 point values are 0.001s -1 、0.01s -1 , 0.1s -1 、1s -1 、10s -1 ;

[0080] Under the restriction of selected temperature and strain rate, carry out extrusion experiment; Collect stress-strain data, and construct hyperbolic sine type Arrhenius equation according to the stress-strain data collected; The expression of described hyperbolic sine type Arrhenius equation The formula is:

[0081]

[0082] In formula (1.1),

[0083] is the strain rate, and its unit is s -1 ;

[0084] T is the average temperature of the extruded billet, and its unit is K;

[0085] R is the molar gas constant, with a valu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com