Functional floor tile produced by using waste PVC and agricultural waste

A technology for agricultural waste and waste polyvinyl chloride, which is applied in the field of production and preparation of plastic floor tiles in the construction industry, can solve problems such as air pollution and human health.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

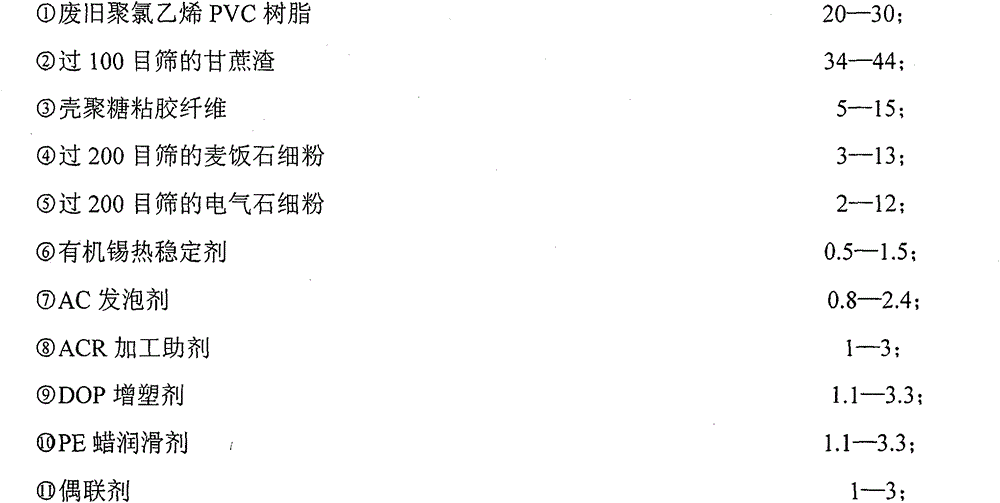

[0041] Embodiment 1: A functional plastic floor tile produced from waste polyvinyl chloride and agricultural waste, which is characterized in that: waste polyvinyl chloride PVC resin and bagasse composite materials are composed of the following material parts by mass: %

[0042]

Embodiment 2

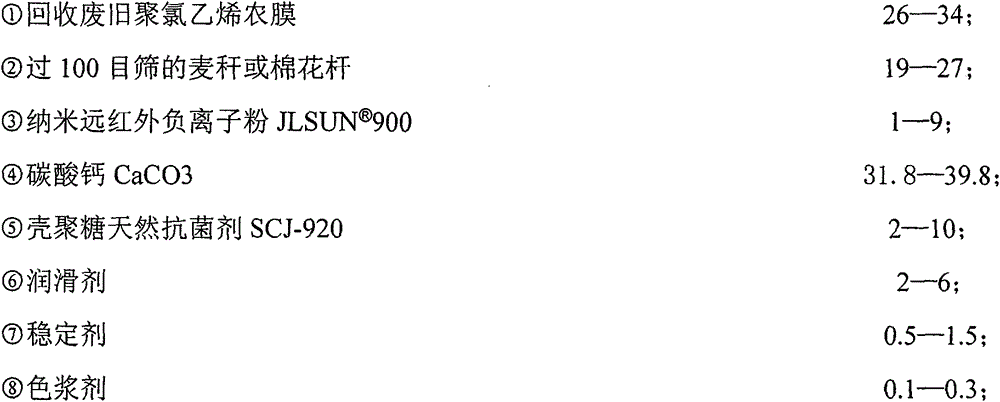

[0043] Embodiment 2: Waste and old polyvinyl chloride agricultural film straws are used to produce plastic floor tiles according to the following proportions by mass %

[0044] 1. Formula:

[0045]

[0046] 2. Preparation method:

[0047] Recycling waste polyvinyl chloride agricultural film and straw such as wheat straw, cotton stalk and calcium carbonate as the main raw materials. The tiles are made into floor tiles, just inspect and pack.

[0048] 3. Performance:

[0049] It is wear-resistant, durable, corrosion-resistant, cool-proof, moisture-proof, non-flammable, natural antibacterial and sterilizing, radiates far-infrared rays, produces trace elements, negative ions, has beautiful color, and is biodegradable and environmentally friendly.

[0050] 4. Use:

[0051] For the production of plastic floor tiles.

Embodiment 3

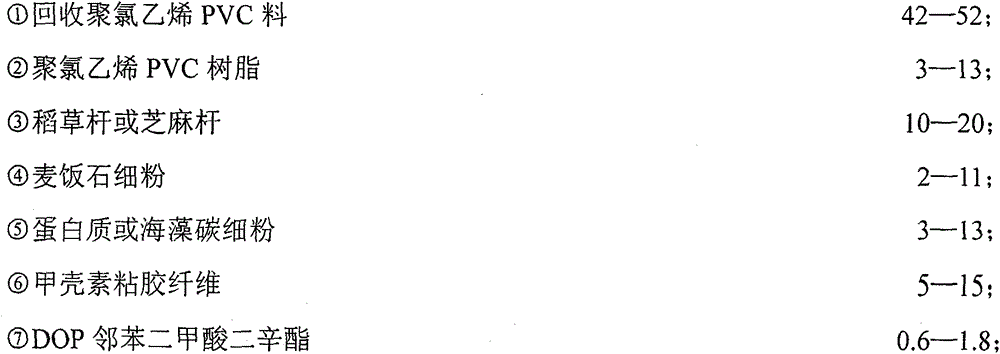

[0052] Embodiment 3: Regenerated polyvinyl chloride straw or sesame stalk non-wood fiber plastic floor tiles are composed according to the following proportions by mass

[0053] 1. Formula:

[0054]

[0055] 2. Preparation method:

[0056] Cleaning and other pretreatment of recycled polyvinyl chloride PVC materials, straw stalks or sesame stalks → crushing materials → compounding → kneading → extruding T-shaped mouth → sheet → calendering with three pairs of calender rollers → cooling → rough cutting → punching

[0057] If the PVC material to be returned contains soft PVC and PVC film, fillers such as CaCO3 can be added appropriately. If the crushed material is used directly, the plasticization is not good after one extrusion, and the pellets should be mixed and melted by extrusion first, and then used as pellets. Extrusion, which is equal to two plasticizations.

[0058] 3. Purpose

[0059] For the production of plastic floor tiles.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com