A high-performance, high-exfoliation corrosion-resistant aluminum alloy profile and its processing technology

An aluminum alloy profile, exfoliation corrosion technology, applied in the field of aluminum alloy hot extrusion, can solve the problems of 7055 alloy exfoliation corrosion, affecting performance and service life, large plastic deformation resistance, etc., to optimize extrusion process parameters, high resistance to spalling, etc. The effect of corrosion and grain refinement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

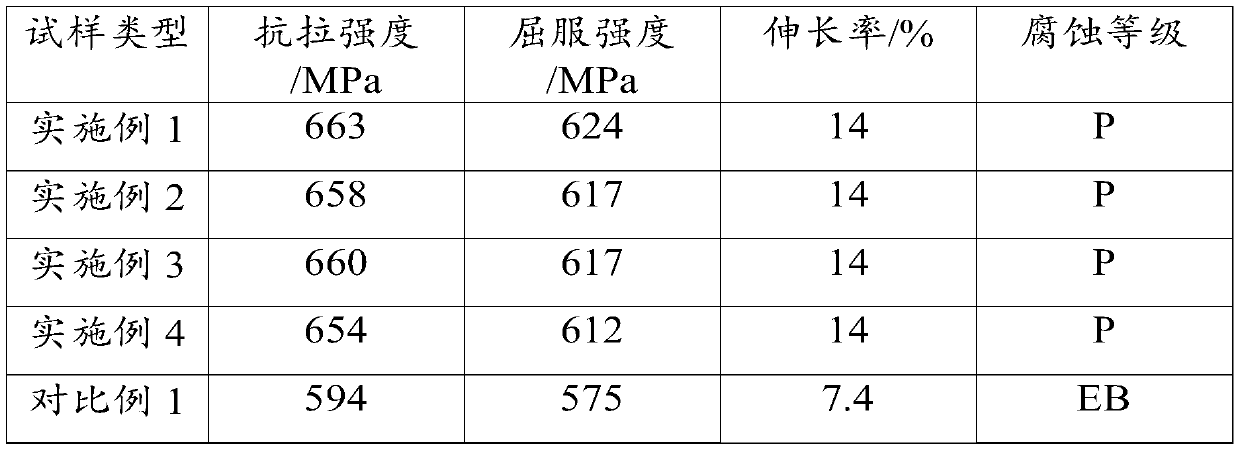

Examples

Embodiment 1

[0023] This embodiment provides a high-performance, high-exfoliation corrosion-resistant aluminum alloy profile, which is mainly produced through the following processing techniques:

[0024] The content of each component of the raw materials for preparing high-performance, high-exfoliation corrosion-resistant aluminum alloy profiles is: Si0.06%, Fe0.08%, Cu2.27%, Mn0.06%, Mg2.04%, Cr0.02%, Zn8 .16%, Ti0.05%, Zr0.16%, rare earth La0.24%, and the balance is Al.

[0025] The raw materials are mixed and cast, and then the melted and cast ingots are subjected to multi-stage homogenization treatment. Specifically, the ingot was soaked at 260° C. for 4 hours, heated to 465° C. for 22 hours, and then heated to 475° C. for 2 hours.

[0026] After the homogenization treatment, the obtained aluminum alloy ingot is sent to an 11MN reverse extruder for extrusion. The extrusion breakthrough pressure is about 8.5MN. The heating temperature of the pressing cylinder is 425°C, the heating te...

Embodiment 2

[0030] This embodiment provides a high-performance, high-exfoliation corrosion-resistant aluminum alloy profile, which is mainly produced through the following processing techniques:

[0031] The content of each component of the raw materials for preparing high-performance, high-exfoliation corrosion-resistant aluminum alloy profiles is: Si0.08%, Fe0.08%, Cu2.24%, Mn0.06%, Mg2.16%, Cr0.02%, Zn8 .12%, Ti0.05%, Zr0.19%, rare earth La0.23%, and the balance is Al.

[0032] The raw materials are mixed and cast, and then the melted and cast ingots are subjected to multi-stage homogenization treatment. Specifically, the ingot was soaked at 262° C. for 3 hours, heated to 468° C. for 20 hours, and then heated to 473° C. for 2 hours.

[0033] After the homogenization treatment, the obtained aluminum alloy ingot is sent to an 11MN reverse extruder for extrusion. The extrusion breakthrough pressure is about 8.5MN. The heating temperature of the pressing cylinder is 432°C, the heating te...

Embodiment 3

[0037] This embodiment provides a high-performance, high-exfoliation corrosion-resistant aluminum alloy profile, which is mainly produced through the following processing techniques:

[0038] The content of each component of the raw materials for preparing high-performance, high-exfoliation corrosion-resistant aluminum alloy profiles is: Si0.08%, Fe0.08%, Cu2.30%, Mn0.06%, Mg2.06%, Cr0.02%, Zn8 .17%, Ti0.05%, Zr0.13%, rare earth La 0.22%, and the balance is Al.

[0039] The raw materials are mixed and cast, and then the melted and cast ingots are subjected to multi-stage homogenization treatment. Specifically, the ingot was soaked at 261° C. for 2 hours, heated to 469° C. for 24 hours, and then heated to 470° C. for 2 hours.

[0040] After the homogenization treatment, the obtained aluminum alloy ingot is sent to an 11MN reverse extruder for extrusion. The extrusion breakthrough pressure is about 8.5MN. The heating temperature of the pressing cylinder is 424°C, the heating t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com