Three degree of freedom plane induction motor

An induction motor, degree of freedom technology, applied in electromechanical devices, electrical components, etc., can solve the problems of large mover structure, poor dynamic response performance, and many parts, etc., and achieve small mover mass, good dynamic performance, zero The effect of fewer parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

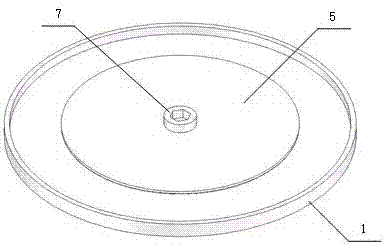

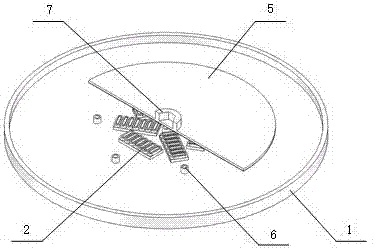

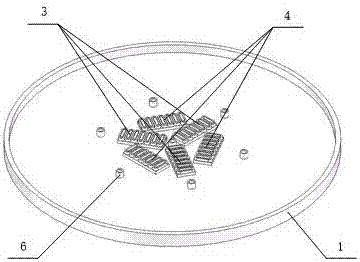

[0022] Such as Figure 1 to Figure 4 As shown, a new three-degree-of-freedom planar induction motor includes a linear drive unit 3 with three stators 2 arranged in a "Y" shape, and a rotary drive unit 4 with three stators 2 arranged in a "△" shape. Cylindrical base 1, bearing 6 and disc-shaped mover 5.

[0023] The drive unit of the induction motor is as image 3 , Figure 4 and Figure 6 As shown, the linear drive unit 3 and the rotary drive unit 4 are both arranged on the base 1 .

[0024] Such as Figure 5 As shown, the bottom surface of the stator 2 is rectangular, and the line connecting the midpoints of the wide sides of the bottom surface is defined as the stator axis 9 .

[0025] The linear drive unit 3 is composed of three stators 2 which are evenly distributed in space around the center of the base 1 . The stator axes 9 of the three stators 2 all pass t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com