A nano-targeted drug carrier, preparation method and application thereof

A targeting and carrier technology, applied in pharmaceutical formulations, drug combinations, anti-tumor drugs, etc., can solve the problems that anti-tumor drugs do not have tumor tissue-targeting effects, affect drug bioavailability, and cannot achieve anti-tumor effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

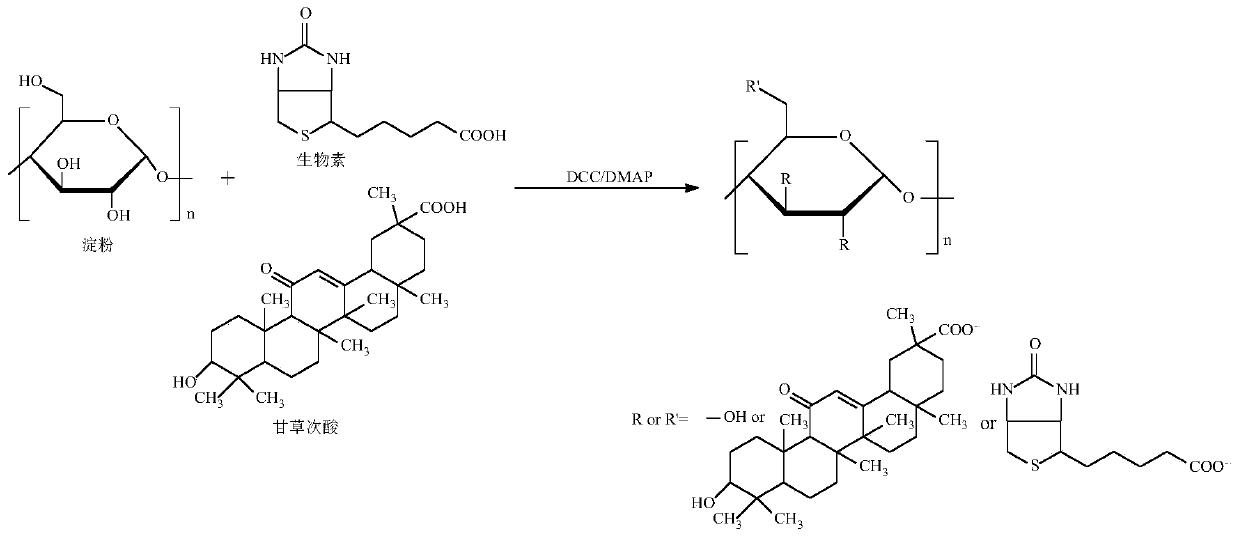

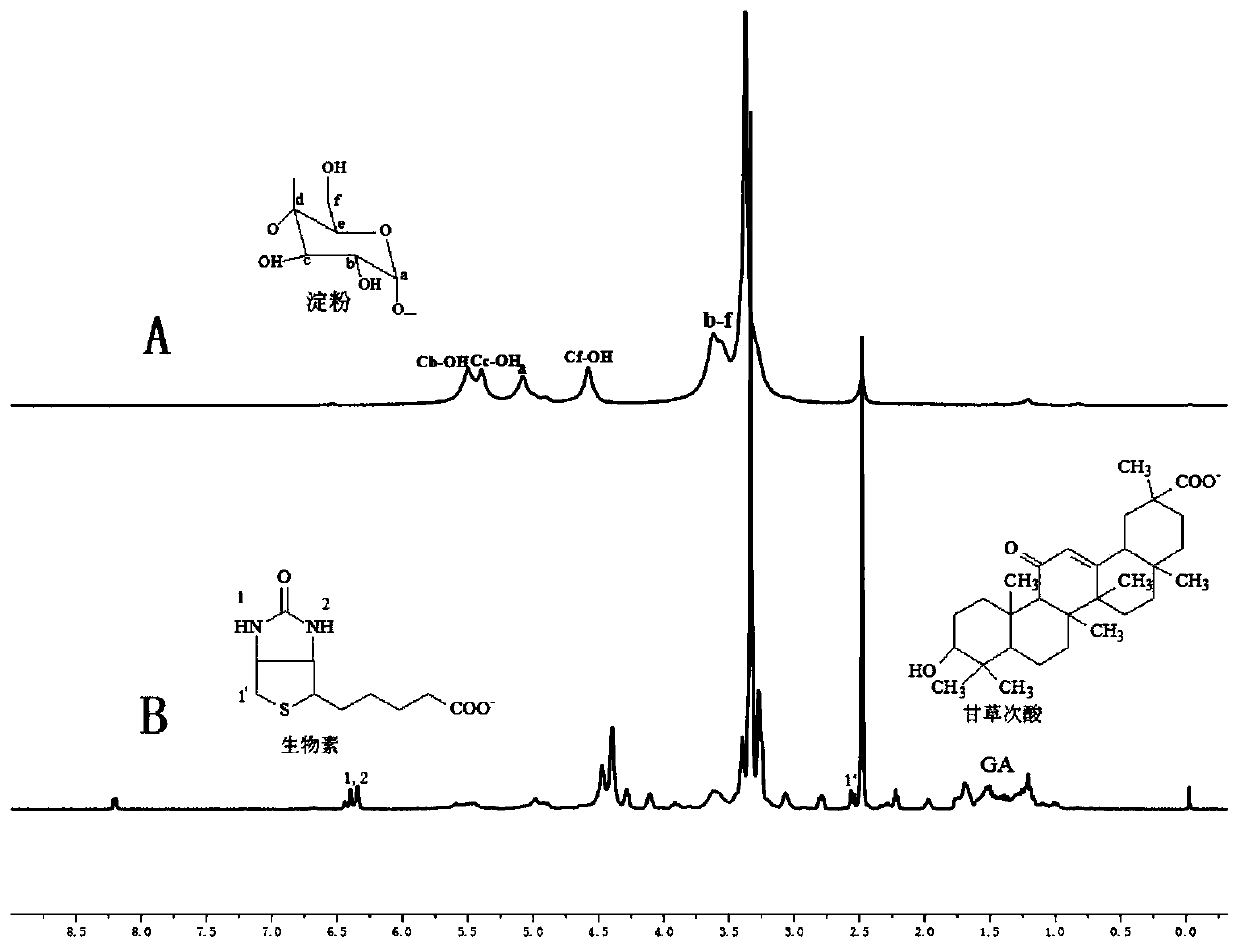

[0031] Experimental principle such as figure 1 , the specific preparation method is as follows:

[0032] a) Reaction step: get 3.0g soluble starch (polymerization degree is 400-800, relative molecular weight is 10 4 -10 6 g / mol), 1.5g biotin and 0.75g 18-β glycyrrhetinic acid were dissolved in 150mL dimethyl sulfoxide and stirred to dissolve, then 0.5g N,N'-dicyclohexylcarbodiimide and 0.25g 4- After dimethylaminopyridine was reacted at room temperature at a stirring speed of 150 rpm for 48 hours, the initial product was obtained;

[0033] b) Dialysis process: put the initial product prepared in the reaction step a) into a dialysis bag (MW8000-14000) and put it into deionized water for dialysis, change the deionized water every 4 hours, continue dialysis for 24 hours, and suction filter. And wash with anhydrous ether and deionized water 3 times respectively to obtain the washings, repeat the above steps 3 times, vacuum freeze-dry the washings for the third time at -50°C to ...

Embodiment 2

[0043] a) Reaction step: get 2.75g soluble starch (degree of polymerization is 400-800, relative molecular weight is 10 4 -10 6 g / mol), 1.25g biotin and 0.63g 18-β glycyrrhetinic acid were dissolved in 150mL DMSO and stirred to dissolve, then 0.6g N,N'-dicyclohexylcarbodiimide and 0.25g 4- After dimethylaminopyridine was reacted at room temperature at a stirring speed of 150 rpm for 48 hours, the initial product was obtained;

[0044] b) Dialysis process: put the initial product prepared in the reaction step a) into a dialysis bag (MW8000-14000) and put it into deionized water for dialysis, change the deionized water every 4 hours, continue dialysis for 24 hours, and suction filter. And wash with anhydrous ether and deionized water 3 times respectively to obtain the washings, repeat the above steps 3 times, vacuum freeze-dry the washings for the third time at -50°C to constant weight, and obtain glycyrrhetinic acid-modified biotin hydrophobic Modified soluble starch;

[004...

Embodiment 3

[0047] a) Reaction step: get 2.5g soluble starch (polymerization degree is 400-800, relative molecular weight is 10 4 -10 6 g / mol), 1.75g biotin and 0.87g 18-β glycyrrhetinic acid were dissolved in 150mL dimethyl sulfoxide and stirred to dissolve, then added 0.75g N,N'-dicyclohexylcarbodiimide and 0.25g 4- After dimethylaminopyridine was reacted at room temperature at a stirring speed of 150 rpm for 48 hours, the initial product was obtained;

[0048] b) Dialysis process: put the initial product prepared in the reaction step a) into a dialysis bag (MW8000-14000) and put it into deionized water for dialysis, change the deionized water every 4 hours, continue dialysis for 24 hours, and suction filter. And wash with anhydrous ether and deionized water 3 times respectively to obtain the washings, repeat the above steps 3 times, vacuum freeze-dry the washings for the third time at -50°C to constant weight, and obtain glycyrrhetinic acid-modified biotin hydrophobic Modified solu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com