Three-dimensional focused-flow micro-fluidic chip used for synthesis of liquid drops and preparation method thereof

A microfluidic chip and manufacturing method technology, applied in chemical instruments and methods, laboratory utensils, laboratory containers, etc., can solve the problems of difficult droplets and difficult to form focused flow, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The embodiments of the present invention will be described in detail below. It should be emphasized that the following description is only exemplary, and is not intended to limit the scope of the present invention and its application.

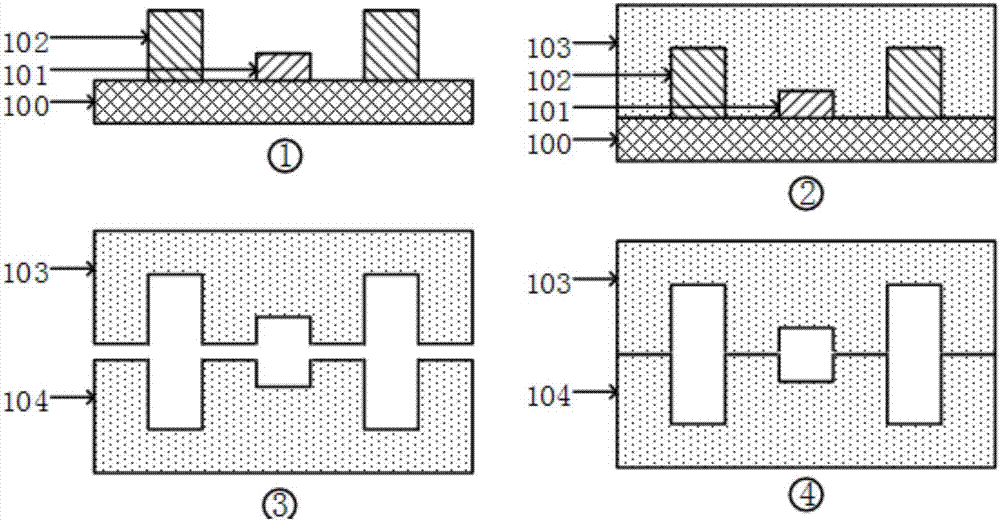

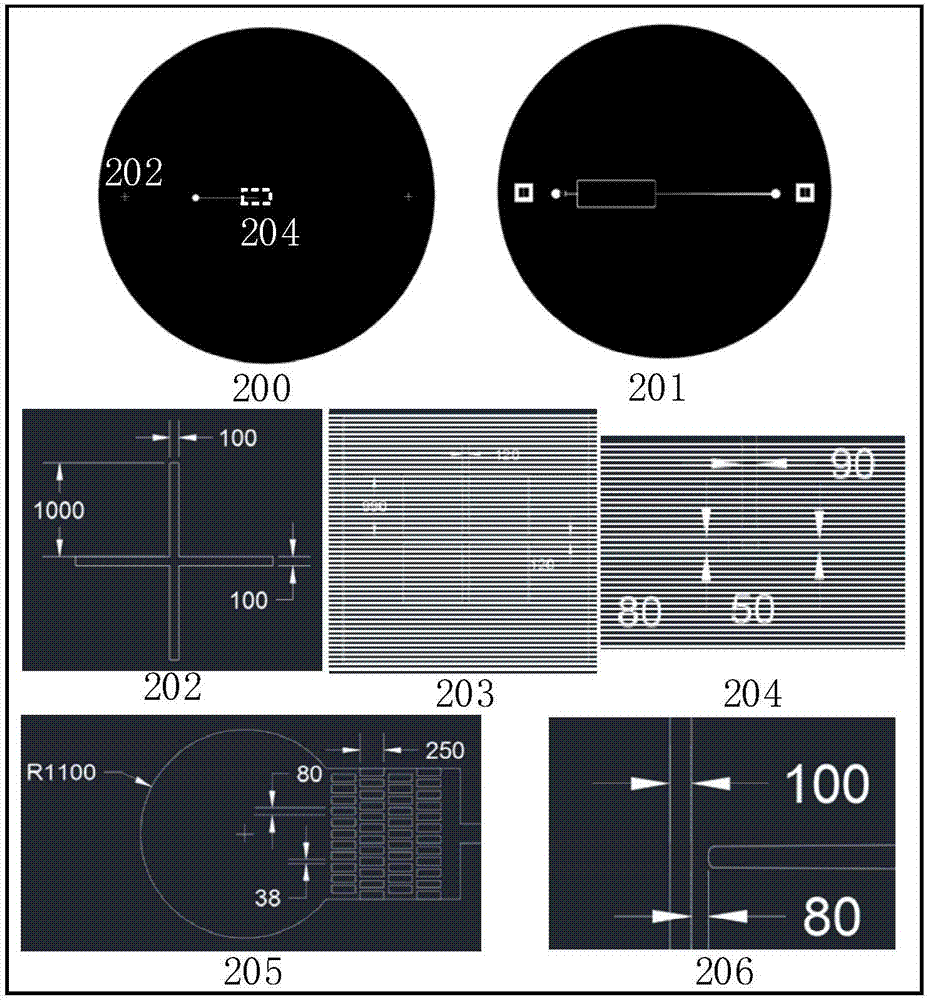

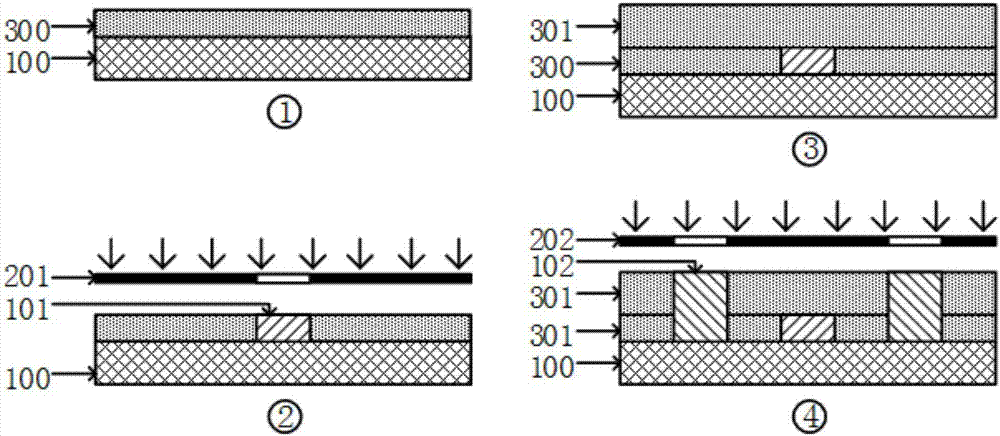

[0036] In one embodiment, a three-dimensional focused flow synthesis droplet microfluidic chip includes a continuous phase layer and a discrete phase layer. The continuous phase layer includes a continuous phase flow channel 502, a continuous phase reservoir 503, and an anti-clogging An array structure 507, a fluid output channel 505 and a fluid output port 506. The discrete phase layer includes a discrete phase channel 501, a discrete phase reservoir 504, and a constriction structure 508; the continuous phase channel 502 is from the continuous phase reservoir Beginning at 503, the anti-clogging array structure 507 filters out the residues in the fluid to form a flow channel, which is divided into two continuous phase flow channels 502 in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com