Intelligent measuring method for temperature of casting flow surface of continuous casting secondary cooling segment

A surface temperature, intelligent measurement technology, applied in the configuration of indicating equipment/measuring equipment, casting equipment, manufacturing tools, etc., can solve the problems of high equipment cost, low precision, high maintenance cost, improve service life, reduce impact, The effect of improving the control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

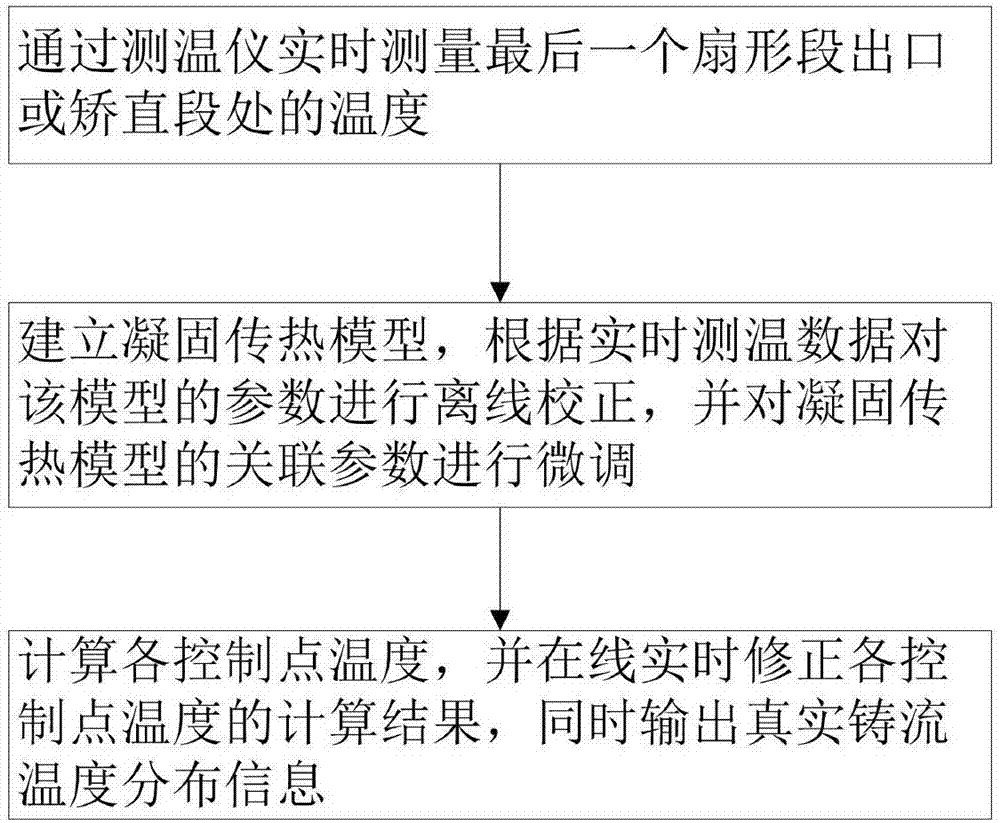

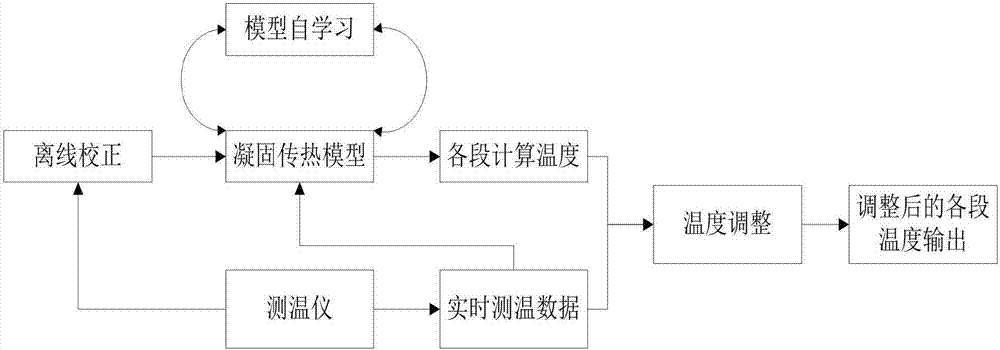

[0037] The invention provides an intelligent measurement method for the surface temperature of the strand in the secondary cooling section of continuous casting, comprising the following steps:

[0038] S1. Measure the temperature at the exit of the last sector or at the straightening section in real time through a thermometer;

[0039] S2. Establish a solidification heat transfer model, perform offline calibration of the parameters of the model according to the real-time temperature measurement data, and fine-tune the associated parameters of the solidification heat transfer model;

[0040]S3. Calculate the temperature of each control point, and correct the calculation results of the temperature of each control point online in real time, and output the real strand temperature distribution information at the same time.

[0041] The thermometer uses a high-precision temperature sensor, and a cooling and protection device is designed for the thermometer to make it completely sea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com