Concrete prefabricated component handling system and handling method

A technology of prefabricated components and handling systems, which is applied in the directions of transportation and packaging, instruments, measuring devices, etc., can solve the problems of high requirements for smoothness of handling roads, low handling flexibility, and large investment in prefabrication fields, and achieves low investment. , the effect of low flatness and low safety risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

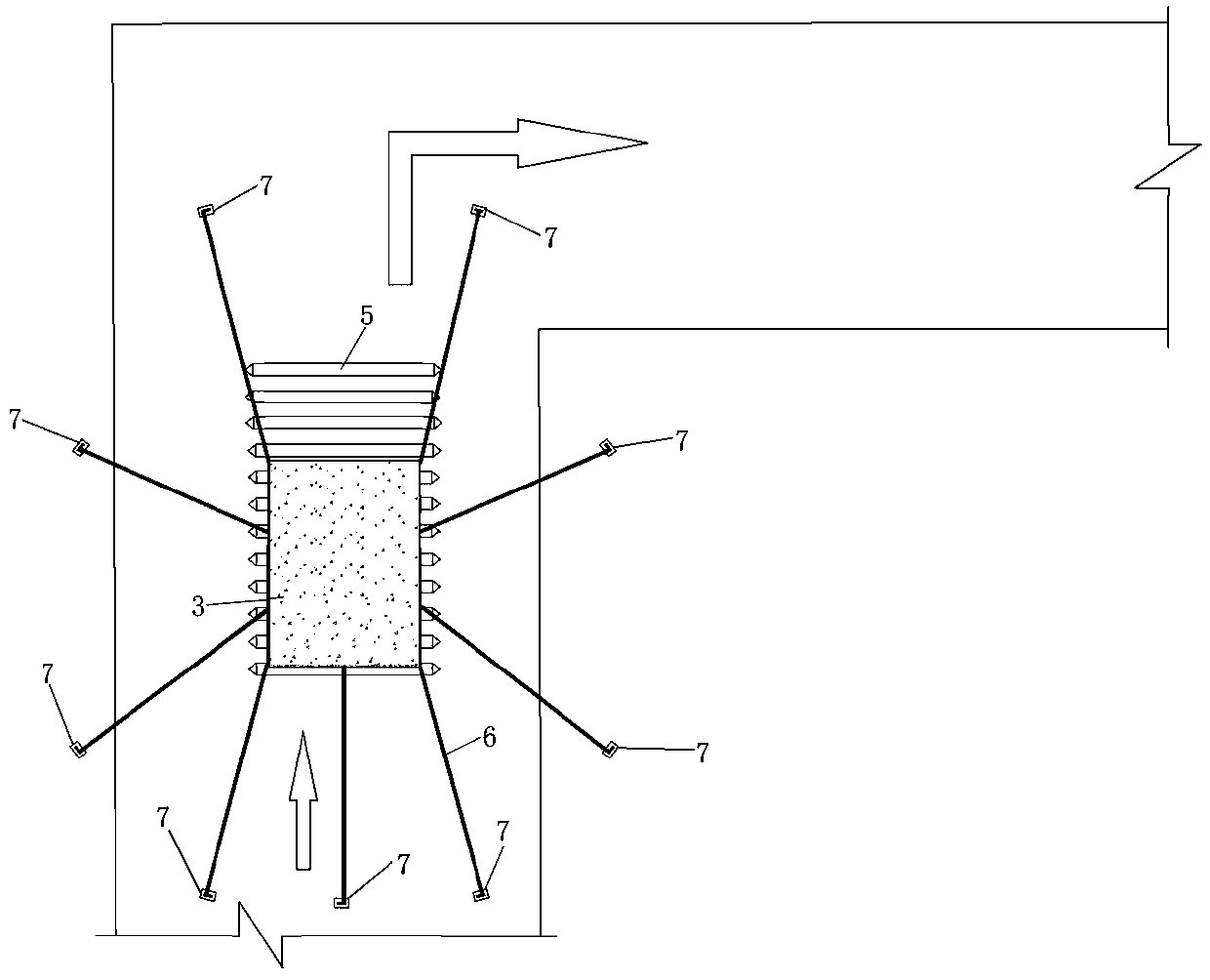

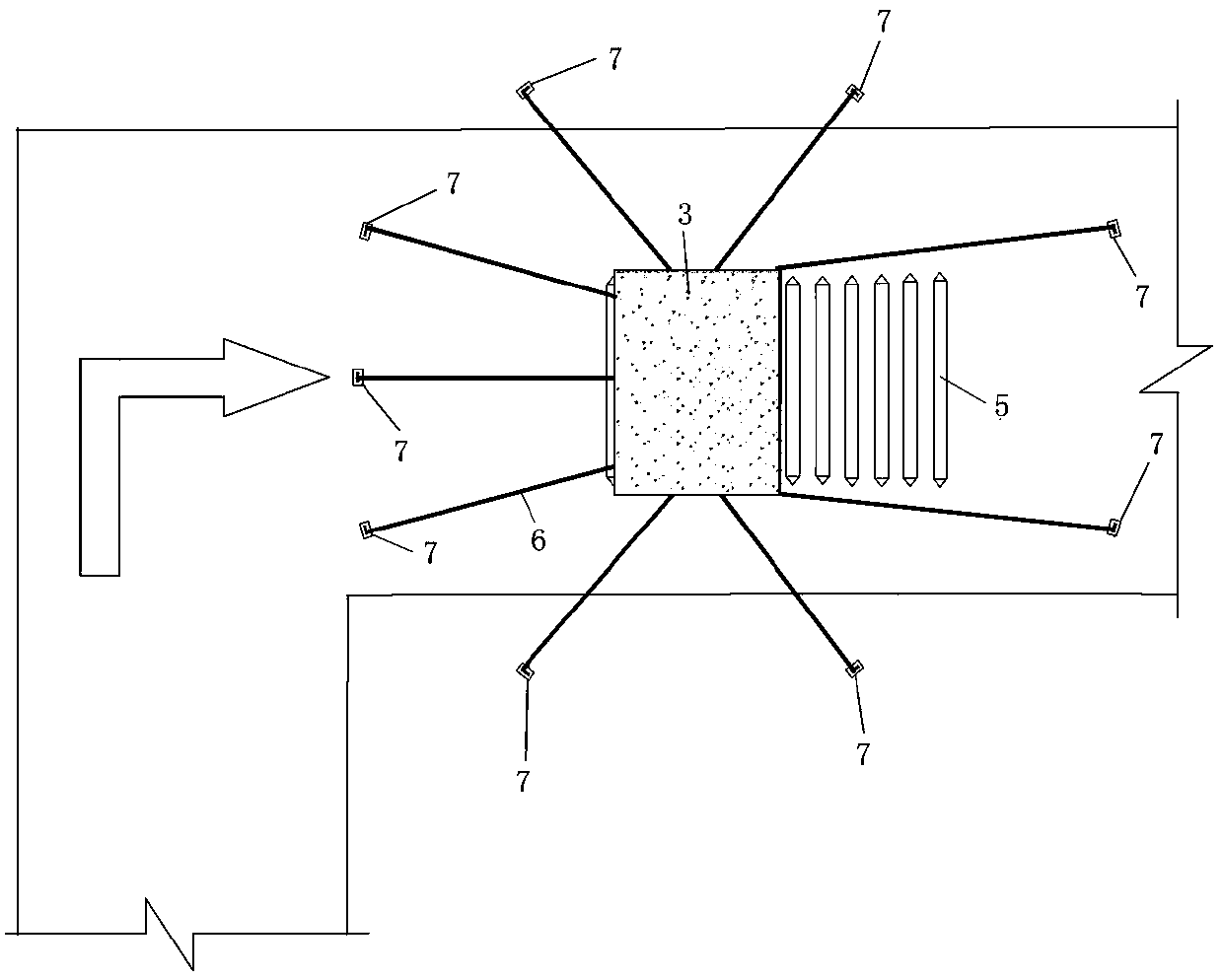

Embodiment 1

[0040] Embodiment 1 also includes a control terminal 10 (the control terminal 10 is preferably a mobile terminal, and the mobile terminal is preferably a tablet computer or a smart phone), and each rolling airbag 5 is provided with an air pressure sensor 11, a temperature sensor 12 and a first wireless signal transmission module 13. An electronic tension gauge 14 and a second wireless signal transmission module 15 are provided on each steel wire rope 6, and several electronic level gauges 16, positioning devices 17 and a third wireless signal transmission module 18 (preferably Zigbee ); the air pressure sensor 11 and the temperature sensor 12 are electrically connected to the control terminal 10 through the first wireless signal transmission module 13, the electronic tension gauge 14 is electrically connected to the control terminal 10 through the second wireless signal transmission module 15, and the Both the electronic level 16 and the positioning device 17 are electrically c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com