Separable pier type cofferdam

A cofferdam and pier type technology is applied in the field of separable pier type cofferdams, which can solve the problems of difficult underwater cutting operations by divers, difficult anticorrosion maintenance of steel cylinders, affecting the service life of structures, etc., and save operation time. , the effect of reducing maintenance workload and costs, and reducing operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

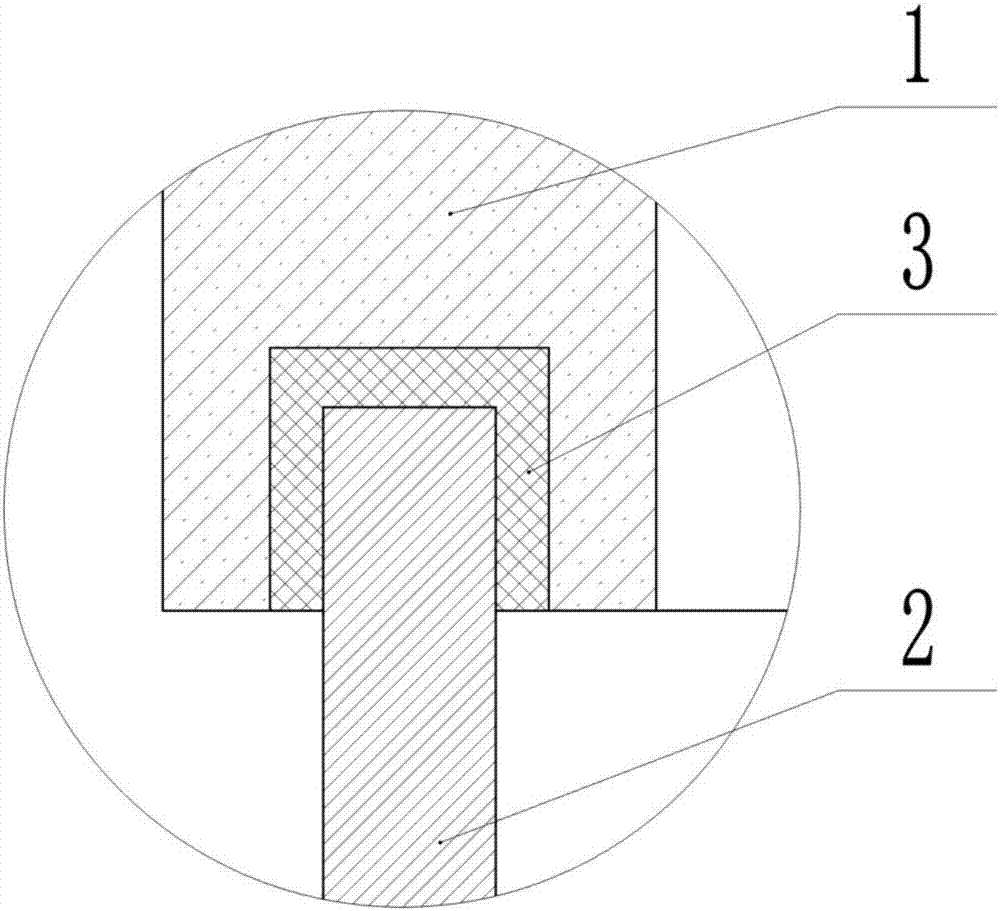

[0020] Example 1 A separable pier cofferdam, such as figure 1 with figure 2 As shown, it includes a reinforced concrete cylinder 1 and a steel cylinder 2. The reinforced concrete cylinder 1 and the steel cylinder 2 are stacked vertically and coaxially. The reinforced concrete cylinder 1 is located on the steel cylinder 2. The bottom of the reinforced concrete cylinder 1 is provided with a limit water stop structure, and the steel cylinder 2 is inserted into the limit water stop structure.

[0021] The limit water stop structure includes an annular groove provided on the bottom surface of the reinforced concrete cylinder 1 and an annular water stop material 3 provided in the annular groove. The top end of the steel cylinder 2 is inserted into the annular groove, and the annular water stop material 3 is arranged between the steel cylinder 2 and the annular groove, and the annular water-stop material 3 is at least attached to the top surface of the steel cylinder 2 and the top surfa...

Embodiment 2

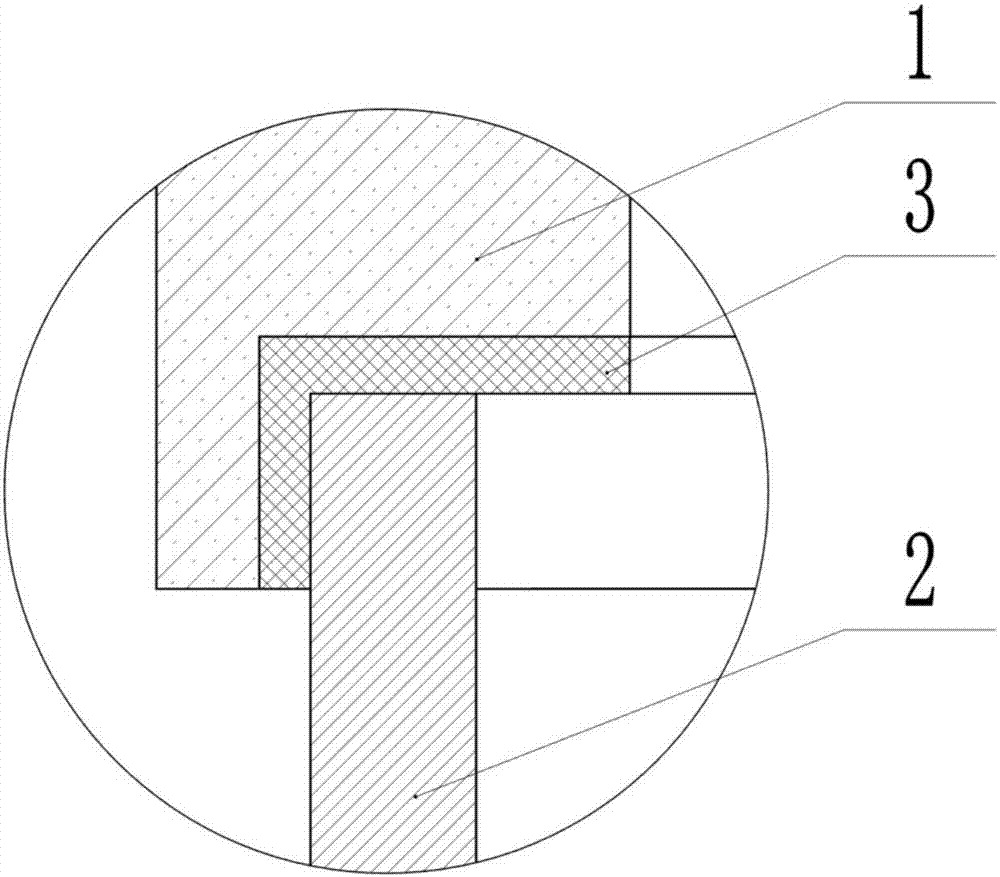

[0025] Example 2 A separable pier cofferdam, such as figure 1 with image 3 As shown, it includes a reinforced concrete cylinder 1 and a steel cylinder 2. The reinforced concrete cylinder 1 and the steel cylinder 2 are stacked vertically and coaxially. The reinforced concrete cylinder 1 is located on the steel cylinder 2. The bottom of the reinforced concrete cylinder 1 is provided with a limit water stop structure, and the steel cylinder 2 is inserted into the limit water stop structure.

[0026] The limit water stop structure includes an annular step provided on the bottom surface of the reinforced concrete cylinder 1 and an annular water stop material 3 provided in the annular step. The top end of the steel cylinder 2 is inserted into the annular step, and the annular water stop material 3 It is arranged between the steel cylinder 2 and the annular step, and the annular water stop material 3 is at least attached to the top surface of the steel cylinder 2 and the top surface of ...

Embodiment 3

[0030] Example 3 A detachable pier cofferdam, such as figure 1 with Figure 4 As shown, it includes a reinforced concrete cylinder 1 and a steel cylinder 2. The reinforced concrete cylinder 1 and the steel cylinder 2 are stacked vertically and coaxially. The reinforced concrete cylinder 1 is located on the steel cylinder 2. The bottom of the reinforced concrete cylinder 1 is provided with a limit water stop structure, and the steel cylinder 2 is inserted into the limit water stop structure.

[0031] The limit water stop structure includes an annular step provided on the bottom surface of the reinforced concrete cylinder 1 and an annular water stop material 3 provided in the annular step. The top end of the steel cylinder 2 is inserted into the annular step, and the annular water stop material 3 It is arranged between the steel cylinder 2 and the annular step, and the annular water stop material 3 is at least attached to the top surface of the steel cylinder 2 and the top surface ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com