Filter ball valve

A technology for filtering ball valves and filtering devices, which is applied in the fields of filtration and separation, valve details, valve devices, etc., can solve the problems of large valve body modification and complex ball valve structure, and achieve the effect of reducing cost pressure, compact structure and good filtering effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

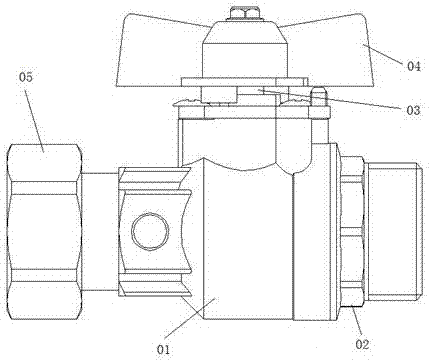

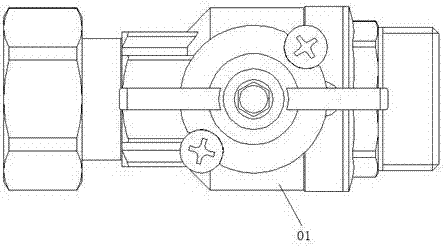

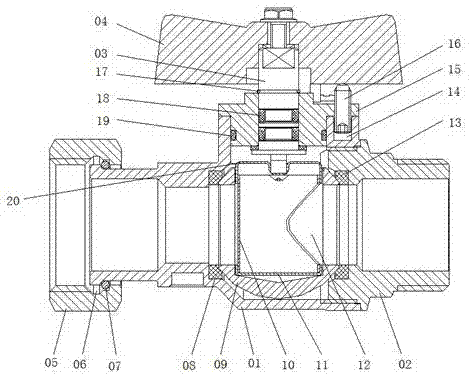

[0030] like figure 1 , figure 2 , image 3 , Figure 4 as well as Figure 5 As shown, a filter ball valve includes a valve body 01, a bonnet 02, a valve stem 03, a handle 04 and a valve ball 09, the handle 04 is fixedly connected to the valve stem 03, and the valve stem 03 is rotatably connected to the locking cap 15, the valve ball 09 is provided with a filtering device, the filtering device includes a filter screen 10, an upper sheath 20 and a lower sheath 11, the filter screen 10 is fixedly connected with the upper sheath 20 and the lower sheath 11 respectively, and the upper sheath The sleeve 20 is fixedly connected with the valve stem 03, the filter screen 10 is cylindrical with the axis coaxial with the valve stem 03, its upper and lower ends are respectively fixedly connected with the upper sheath 20 and the lower sheath 11, and the valve ball 09 A circular blind hole with an upward opening perpendicular to the flow channel is provided on the top, the filter screen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com