Testing apparatus for curing degree of colored layer of optical fiber

A technology for testing devices and coloring layers, applied to measuring devices, mechanical devices, instruments, etc., can solve problems such as large randomness, and achieve the effects of easier acquisition, high test accuracy, and high contrast

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

[0032] The main purpose of the present invention is to provide a test device that can fix the wiping force, wiping range, and wiping times, and solve the problem of non-standardization of each person's operation in a targeted manner, control the wiping strength through air pressure, and be able to set the wiping range and wiping times .

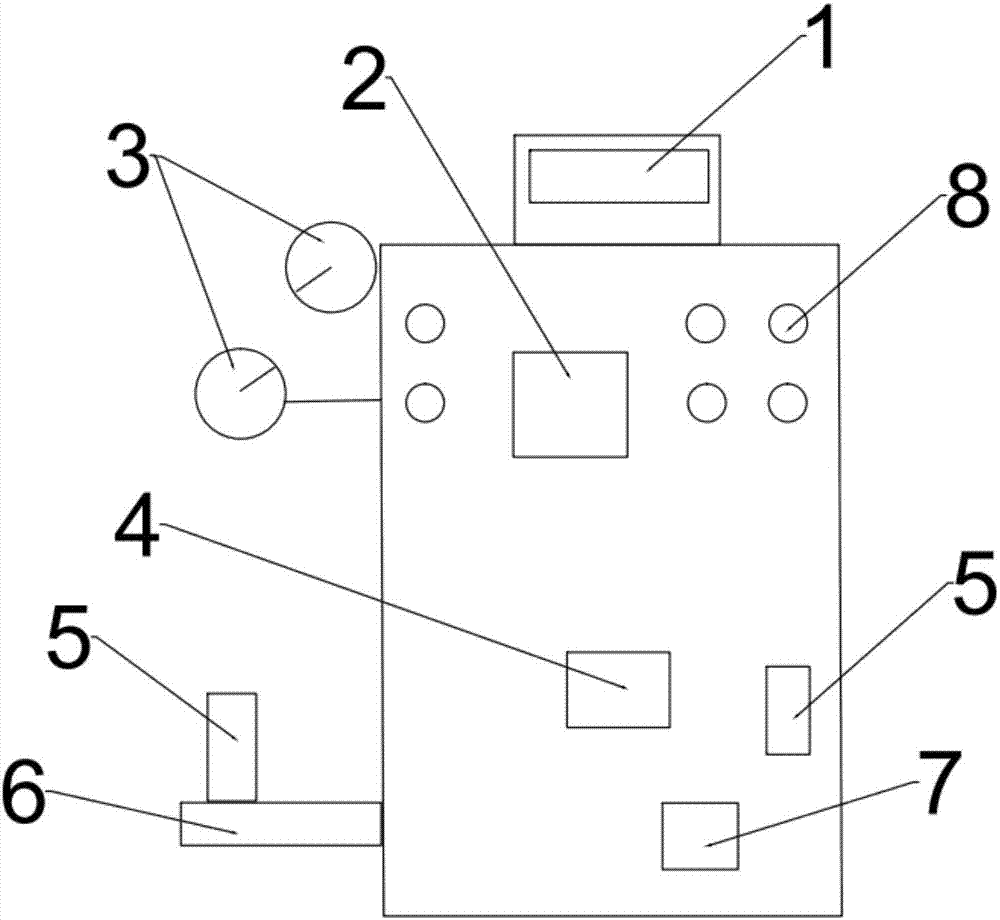

[0033] Specifically, refer to figure 1 , figure 1 It is a structural schematic diagram of the curing degree testing device of the optical fiber coloring layer of the present invention.

[0034] Such as figure 1 As shown, a preferred embodiment of the present invention proposes a device for testing the curing degree of the colored layer of an optical fiber, including: a reciprocating cylinder 4 for reciprocating wiping action, connected to the reciprocating cylinder 4, driven and c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com