Housing assembly of electric power steering device and device of same

An electric power steering and assembly technology, applied in electric steering mechanism, power steering mechanism, steering mechanism, etc., can solve problems such as damage to components such as gear fan shaft steering nuts, high structural strength requirements for key components, and difficulty in electromechanical matching. , to achieve the effect of good assembly, easy and flexible layout, and saving space in the car

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0070] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0071] In this article, if there is no special explanation, when involving formulas, " / " means division, and "×" and "*" mean multiplication.

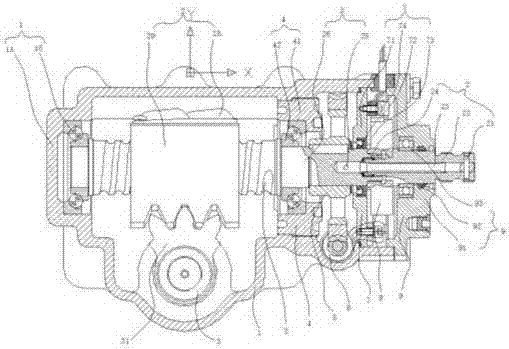

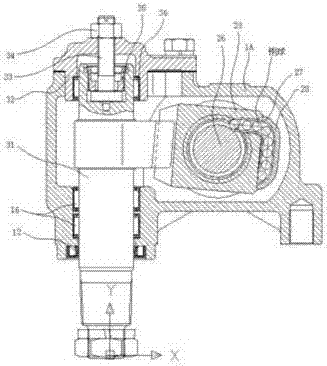

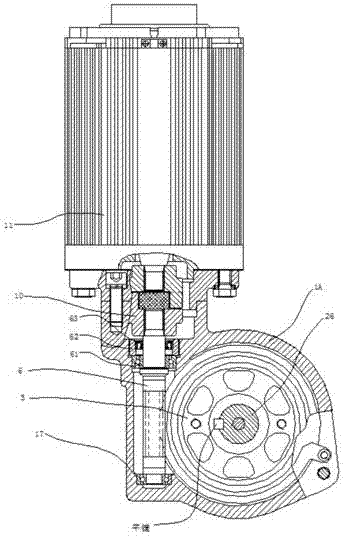

[0072] Such as Figure 17As shown in -18, a housing assembly of an electric power steering device, the housing assembly (1) includes a first installation cavity 1-1, a second installation cavity 1-2 and a third installation cavity 1-3 , the first installation cavity 1-1 is arranged along the horizontal direction and is a non-through cavity, the second installation cavity 1-2 is a non-through cavity, and the third installation cavity 1-3 is Through cavity, the first installation cavity 1-1 communicates with the second installation cavity 1-2, the first installation cavity 1-1 communicates with the third installation cavity 1-3, and the second installation cavity 1 -2 is not communicated with the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com