Hoisting system and method for hoisting high and large anaerobic jar body through low davit group

An anaerobic tank and anaerobic tank technology are applied in the field of hoisting systems for tall and large anaerobic tanks, and can solve the problems of increased safety investment in high-altitude operations, large and complex suspender power systems, and increased operator safety risks, etc. The effect of shortening the construction period, effectively controlling the construction cost and improving the construction quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

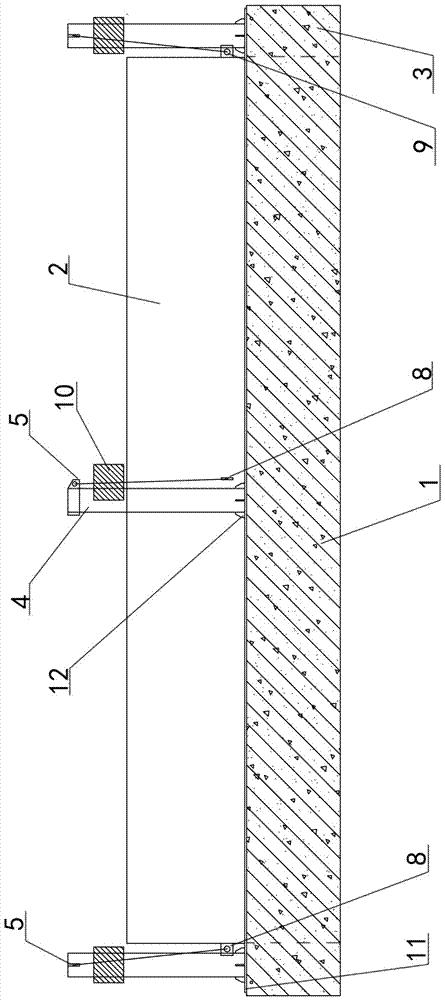

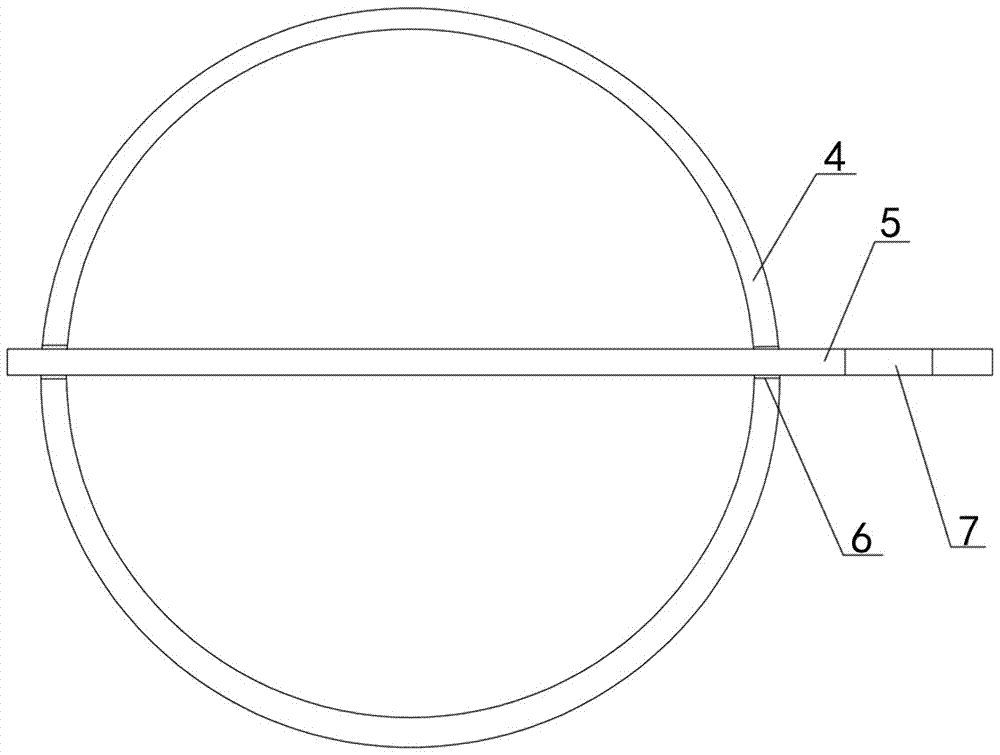

[0050] Examples see Figure 1-4As shown, a tall anaerobic tank body is hoisted by low group davits. The anaerobic tank body has a diameter of 15m, a height of 30m, a total of fifteen circles of wall panels, a total weight of 200 tons, and a volume of 4800 cubic meters. Can. Due to the large size of the tank, it cannot be directly transported to the site. According to its particularity, the production and installation of the tank can only be completed on site. Combined with the tank hoisting scheme, after repeated research and design, it is determined to use the low group of hanging columns to hoist the tall An upside-down hoisting method for an anaerobic tank hoisting system.

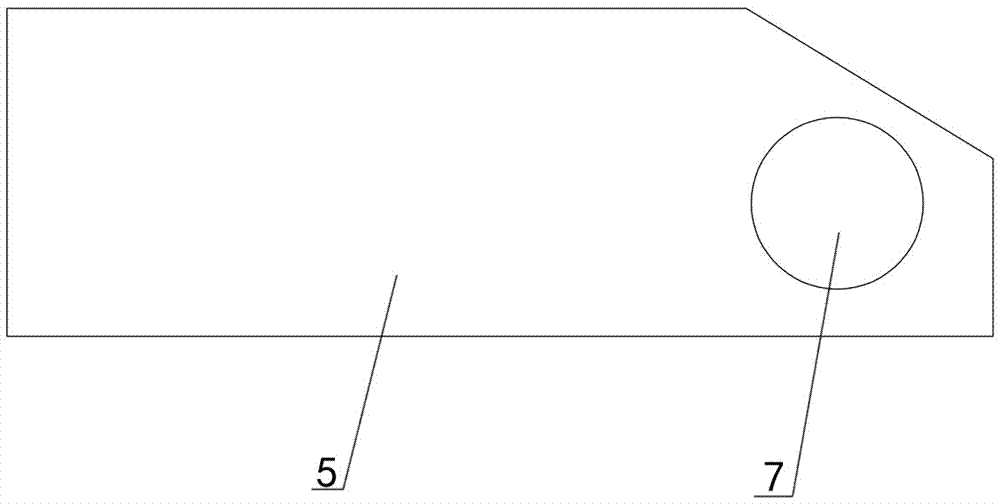

[0051] The hoisting system includes an anaerobic tank foundation 1 and a circle of wall panels 2 of the anaerobic tank, the diameter of the anaerobic tank foundation 1 is greater than the diameter of the wall panel 2, and the part of the anaerobic tank foundation beyond the side wall of the wall panel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com