Tea-saponin-modified oil shale ash and composite floor tile prepared from same and waste plastic

A technology of oil shale ash and waste plastics, applied in construction, building structure, floor, etc., can solve the problems affecting the performance of composite floor tiles, poor compatibility of two phases, complicated production process, etc., to achieve improved combination, Effect of improving performance and reducing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

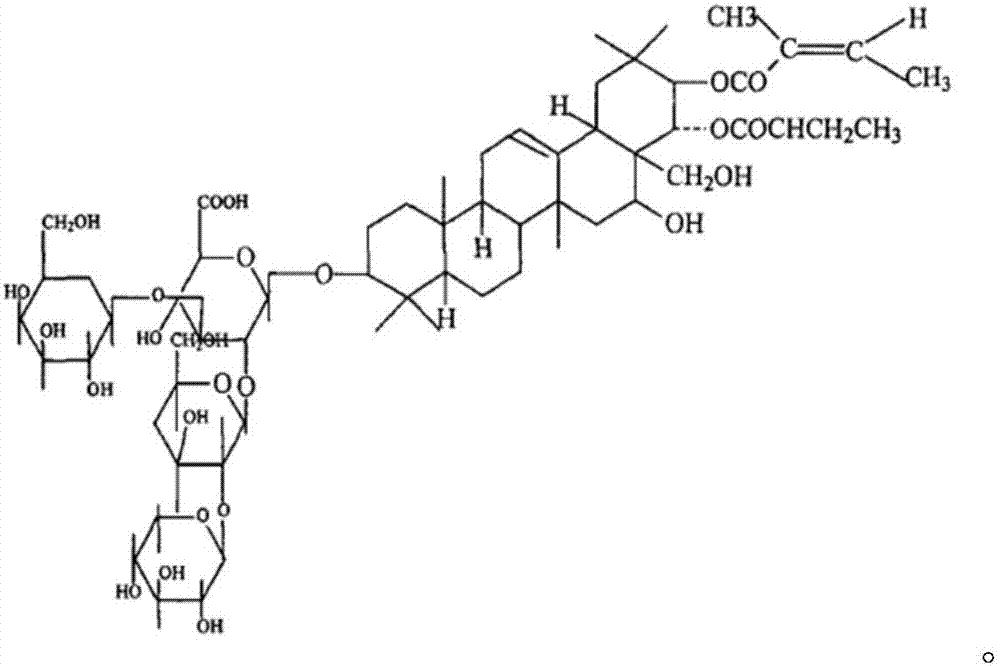

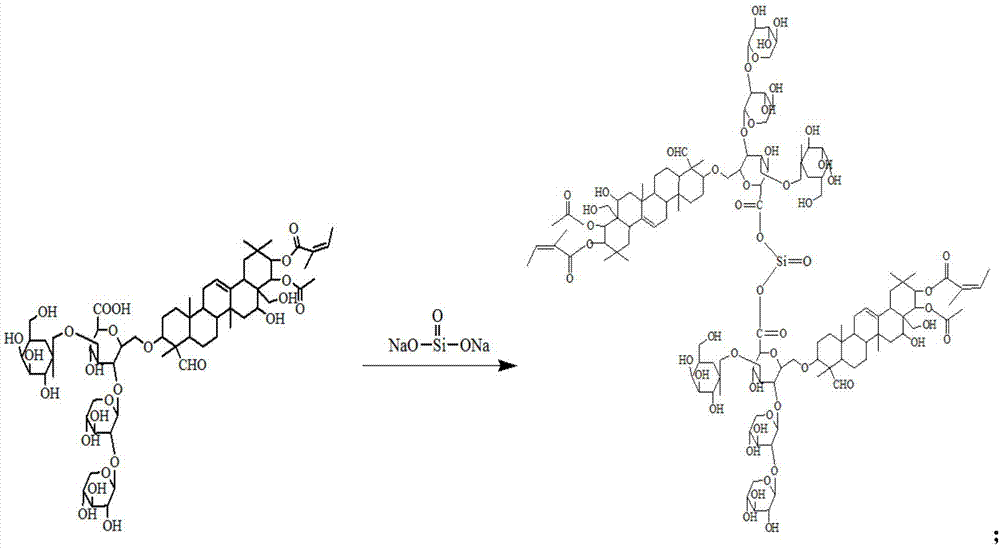

[0031] Make tea saponin modified oil shale ash according to the following steps:

[0032] Add 95Kg oil shale ash and 2Kg NaOH into a high-speed mixer at 20°C, stir for 4-6 minutes, add 3Kg tea saponin at 60°C and heat and stir for 3-4 minutes to obtain tea saponin modified oil shale Ash.

[0033] Follow the steps below to make composite floor tiles:

[0034] a. After washing 200Kg of waste polyvinyl chloride plastic, dry it at 110°C for 1 hour, and then crush it to less than 5mm to obtain product A;

[0035] b. After mixing product A and 800Kg tea saponin modified oil shale ash with a high-speed mixer, product B is obtained;

[0036] c. Put product B on a three-roller mill and masticate it into a sheet at a temperature of 120-160°C and a sheet thickness of 0.5-0.8mm, and then send it to a hot press for molding at a temperature of 140°C-160°C and a pressure of 3.0 MPa, time 3-4 minutes, get C product;

[0037] d. Cut product C into pieces according to the standard size of 3...

Embodiment 2

[0061] Make tea saponin modified oil shale ash according to the following steps:

[0062] Add 94Kg oil shale ash and 3Kg NaOH into a high-speed mixer at 20°C, stir for 4-6 minutes, add 4Kg tea saponin at 60°C and heat and stir for 3-4 minutes to obtain tea saponin modified oil shale Ash.

[0063] Follow the steps below to make composite floor tiles:

[0064] a. After washing 250Kg of waste polyvinyl chloride plastic, dry it at 110°C for 1 hour, and then crush it to less than 5mm to obtain product A;

[0065] b. After mixing product A and 750Kg tea saponin modified oil shale ash with a high-speed mixer, product B is obtained;

[0066] c. Put product B on a three-roller mill and masticate it into a sheet at a temperature of 120-160°C and a sheet thickness of 0.5-0.8mm, and then send it to a hot press for molding at a temperature of 140°C-160°C and a pressure of 3.0 MPa, time 3-4 minutes, get C product;

[0067] d. Cut product C into pieces according to the standard size of 3...

Embodiment 3

[0091] Make tea saponin modified oil shale ash according to the following steps:

[0092] Add 92Kg oil shale ash and 3Kg NaOH into a high-speed mixer at 20°C, stir for 4-6 minutes, add 5Kg tea saponin at 60°C and heat and stir for 3-4 minutes to obtain tea saponin modified oil shale Ash.

[0093] Follow the steps below to make composite floor tiles:

[0094] a. After cleaning 300Kg of waste polyvinyl chloride plastic, dry it at 110°C for 1 hour, and then crush it to less than 5mm to obtain product A;

[0095] b. After mixing product A and 700Kg tea saponin modified oil shale ash with a high-speed mixer, product B is obtained;

[0096] c. Put product B on a three-roller mill and masticate it into a sheet at a temperature of 120-160°C and a sheet thickness of 0.5-0.8mm, and then send it to a hot press for molding at a temperature of 140°C-160°C and a pressure of 3.0 MPa, time 3-4 minutes, get C product;

[0097] d. Cut product C into pieces according to the standard size of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com