Novel piperazine pyrophosphate flame retardant and preparation method thereof

A piperazine pyrophosphate and flame retardant technology, which is applied in the field of flame retardants, can solve the problems of easy agglomeration of flame retardants, reduced flame retardant efficiency, and restrictions on the application of piperazine flame retardants, and achieve good dispersion performance, Effect of improving flame retardancy and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

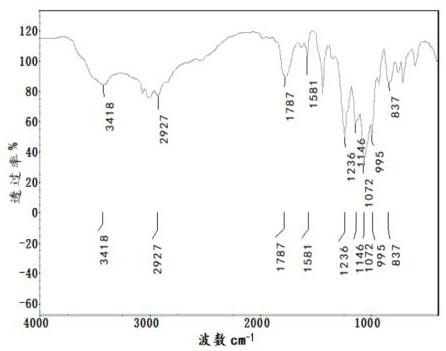

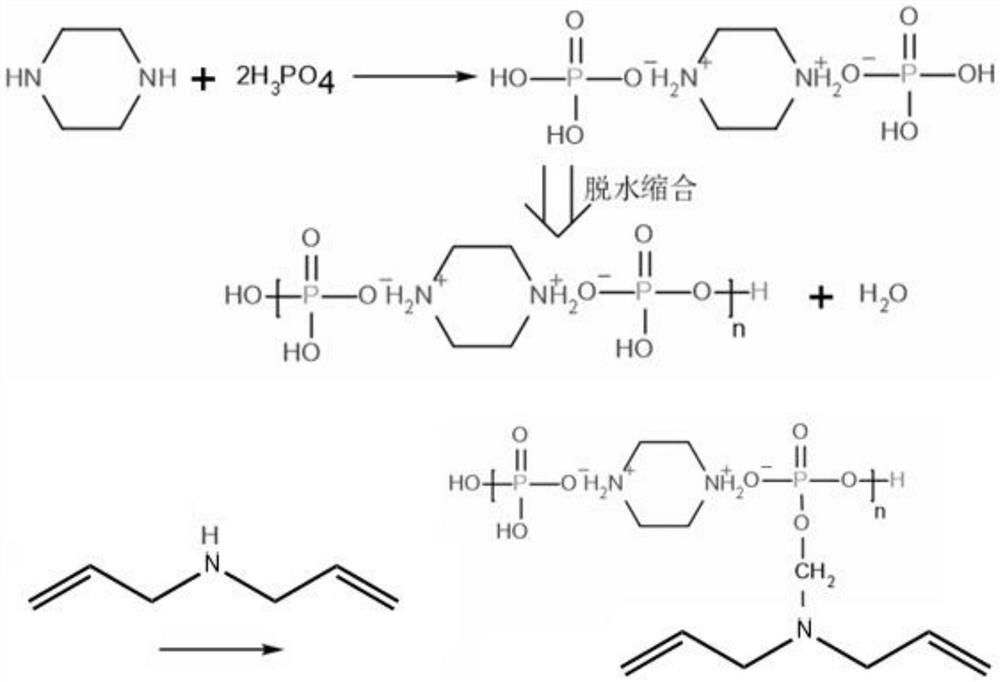

Image

Examples

Embodiment 1

[0035] A novel piperazine pyrophosphate flame retardant and a preparation method thereof, is characterized in that it comprises the following steps:

[0036]Step 1: Add 100kg of distilled water, 15kg of 2-piperazine carboxylic acid, and 34kg of phosphoric acid into the reaction kettle, pass nitrogen into the reaction kettle, fully remove the air, stir at 100r / min for 30min to fully dissolve the materials, and heat the reaction solution to 80°C , reacted for 2 hours, then lowered the temperature to 0°C, white crystals were precipitated, washed with ice distilled water, and filtered under reduced pressure to obtain white crystals, then put the obtained white crystals into a conical dryer, dried at 100°C for 4 hours, and removed water, then Transfer the powder to a vacuum kneader, raise the temperature to 220°C, keep it warm for 60 minutes, and then cool to room temperature to obtain pyrophosphate piperazine powder;

[0037] Step 2, react 3kg of diallylamine, 30kg of pyrophosphat...

Embodiment 2

[0041] A novel piperazine pyrophosphate flame retardant and a preparation method thereof, is characterized in that it comprises the following steps:

[0042] Step 1: Add 109kg of distilled water, 15kg of 2-piperazinone, and 35kg of phosphoric acid into the reaction kettle, feed nitrogen into the reaction kettle, fully remove the air, stir at 133r / min for 36min to fully dissolve the materials, and heat the reaction solution to 83°C. Reacted for 2 hours, then lowered the temperature to 2°C, white crystals were precipitated, washed with ice distilled water, and filtered under reduced pressure to obtain white crystals, then put the obtained white crystals into a conical dryer, dried at 103°C for 3 hours, and removed water, then put Transfer the powder to a vacuum kneader, raise the temperature to 228°C, keep it warm for 47 minutes, and then cool to room temperature to obtain pyrophosphate piperazine powder;

[0043] Step 2, react 4kg of diallylamine, 32kg of pyrophosphate piperazi...

Embodiment 3

[0047] A novel piperazine pyrophosphate flame retardant and a preparation method thereof, is characterized in that it comprises the following steps:

[0048] Step 1: Add 115kg of distilled water, 15kg of piperazine, and 37kg of phosphoric acid into the reaction kettle, pass nitrogen into the reaction kettle, fully remove the air, stir at 176r / min for 47min to fully dissolve the materials, heat the reaction solution to 85°C, and react for 2h , then lower the temperature to 3°C, white crystals are precipitated, washed with ice distilled water, and filtered under reduced pressure to obtain white crystals, then put the obtained white crystals in a conical dryer, dry at 106°C for 2 hours, remove moisture, and then transfer the powder In a vacuum kneader, raise the temperature to 235°C, keep it warm for 42 minutes, and then cool to room temperature to obtain pyrophosphate piperazine powder;

[0049] Step 2, react 7 powders, 0.9kg of dispersion stabilizer at 77°C for 0.9h;

[0050] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com