High-belite sulphoaluminate cement-based hardener for concrete floor and preparation method of high-belite sulphoaluminate cement-based hardener

A special sulfur aluminate, cement-based technology, applied in the field of concrete, can solve problems such as hollowing delamination, plastic cracking, etc., and achieve the effects of performance enhancement, ultra-high strength and surface hardness, and ultra-high bond strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1I

[0023] Embodiment 1I type cement-based hardener

[0024] High Belite Sulphoaluminate Cement: Strength Class 42.5 18%

[0025] Aggregate: 6-10 mesh quartz sand 36%, 40-70 mesh quartz sand 20%, 70-140 mesh quartz sand 5%

[0026] Calcined Kaolin: 5%

[0027] Lime: 1.5%,

[0028] Other mineral admixtures: silica fume 4%, mineral powder 5%

[0029] Rubber powder: 1.0%

[0030] Retarder: tartaric acid 0.05%, citric acid 0.05%

[0031] Water reducer: 0.1%

[0032] Pigment: Titanium Dioxide 2.5%, Iron Oxide Red 1.5%

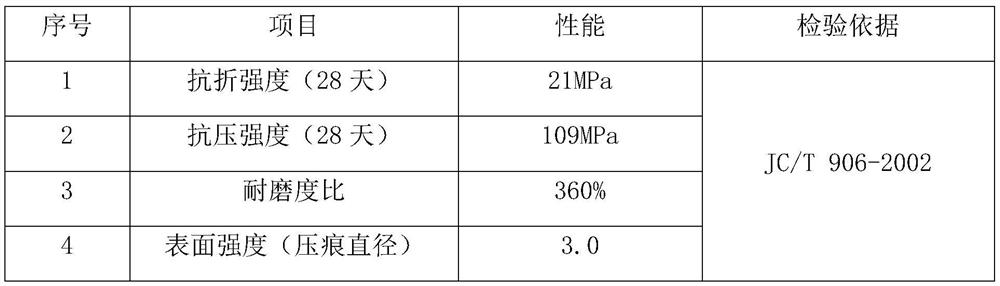

[0033] The specific performance is shown in Table 1.

[0034] Table 1 Material physical and chemical performance indicators

[0035]

Embodiment 2II

[0036] Embodiment 2Type II cement-based hardener

[0037] High Belite Sulphoaluminate Cement: Strength Class 52.5 16%

[0038] Aggregate: Graded Carborundum 63%

[0039] Calcined Kaolin: 5%

[0040] Lime: 1.5%,

[0041] Other mineral admixtures: silica fume 4%, mineral powder 5%

[0042] Rubber powder: 1.0%

[0043] Retarder: tartaric acid 0.05%, citric acid 0.05%

[0044] Water reducer: 0.1%

[0045] Pigment: Titanium Dioxide 2.0%, Carbon Black 2.5%

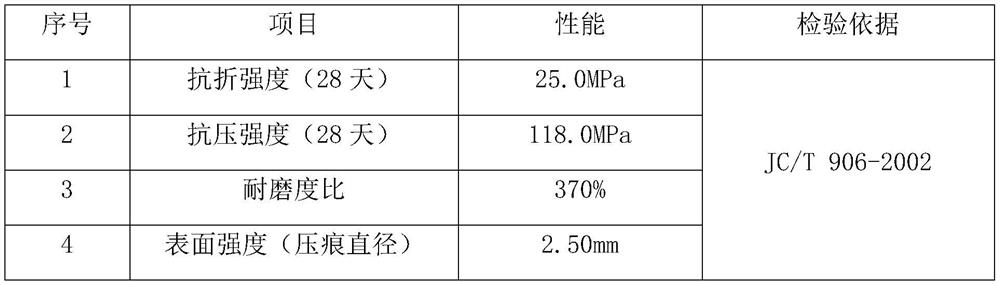

[0046] The specific performance is shown in Table 2.

[0047] Table 2 Physical and chemical performance indicators of materials

[0048]

Embodiment 3I

[0049] Embodiment 3I type cement-based hardener

[0050] High Belite Sulphoaluminate Cement: Strength Grade 42.5 19.5%

[0051] Aggregate: 6-10 mesh quartz sand 36%, 40-70 mesh quartz sand 20%, 70-140 mesh quartz sand 5% Calcined kaolin: 5%

[0052] Lime: 1.5%,

[0053] Other mineral admixtures: silica fume 4%, mineral powder 5%

[0054] Rubber powder: 1.0%

[0055] Retarder: tartaric acid 0.05%, citric acid 0.05%

[0056] Water reducer: 0.1%

[0057] Pigment: Titanium Dioxide 2.5%

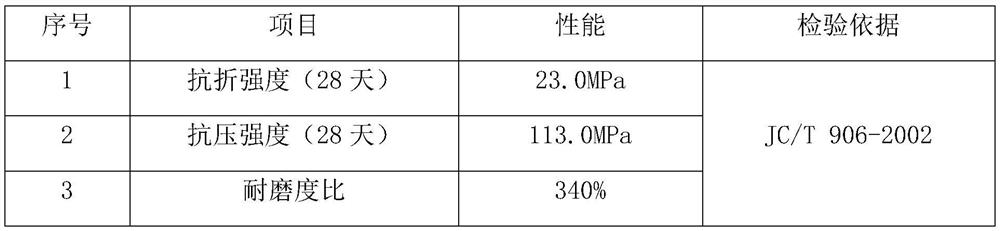

[0058] The specific performance is shown in Table 3.

[0059] Table 3 Physical and chemical performance indicators of materials

[0060]

[0061]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com