Dispersible ethylene-propylene copolymer and preparation method thereof

An ethylene-propylene copolymer, dispersed technology, applied in the field of dispersed ethylene-propylene copolymer and its preparation, can solve the problems of multi-energy, consumption, lengthy and complicated process, etc., and achieve the effects of simple preparation method, cost reduction and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

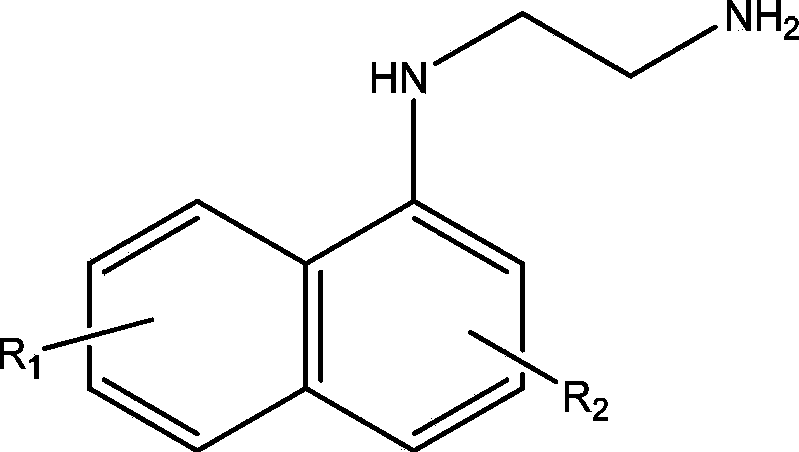

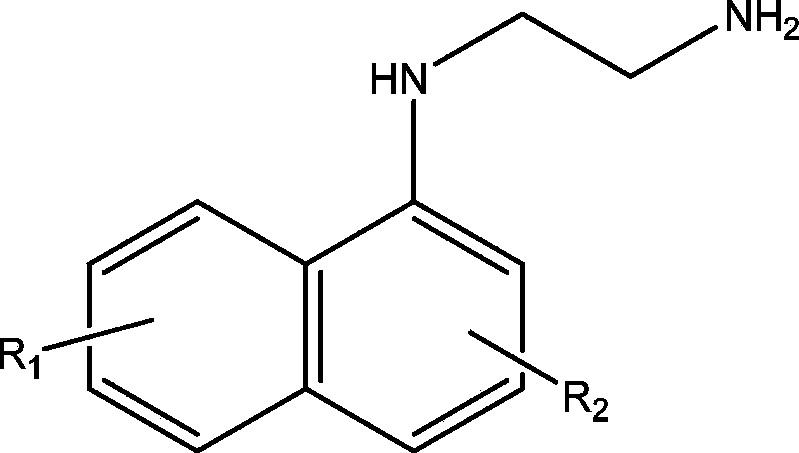

[0020] Add 50g maleic anhydride-grafted ethylene-propylene copolymer (10% graft rate) and 1000g III base oil into a four-neck flask with stirring and nitrogen protection, and dissolve at a temperature of 130°C for about 4 hours. Then the temperature was raised to 150°C, and under the protection of nitrogen, 0.25 g of N-(1-naphthyl)ethylenediamine was added, and the mixture was reacted at 150°C for 6 hours. Utilize vacuum distillation to extract, the internal pressure during extraction is 2mmHg, extraction temperature is 200 ℃, extract 2 hours, remove the unreacted N-(1-naphthyl)ethylenediamine and its derivatives, Finally, the dispersed ethylene-propylene copolymer, that is, the dispersed viscosity index improver product a-1, was obtained.

Embodiment 2

[0022] Add 50g maleic anhydride-grafted ethylene-propylene copolymer (5% graft rate) and 1000g III base oil into a four-neck flask with stirring and nitrogen protection, and dissolve at a temperature of 130°C for about 4 hours. Keeping the temperature, under the protection of nitrogen, 0.5 g of N-(1-naphthyl)ethylenediamine was added and reacted for 6 hours. Utilize vacuum distillation to extract, the internal pressure during extraction is 2mmHg, extraction temperature is 200 ℃, extract 2 hours, remove the unreacted N-(1-naphthyl)ethylenediamine and its derivatives, Finally, the dispersed ethylene-propylene copolymer, namely the dispersed viscosity index improver product a-2, was obtained.

Embodiment 3

[0024] Add 50g maleic anhydride-grafted ethylene-propylene copolymer (5% graft rate) and 1000g III base oil into a four-neck flask with stirring and nitrogen protection, and dissolve at a temperature of 130°C for about 4 hours. The temperature was raised to 170° C., under the protection of nitrogen, 1 g of N-(1-naphthyl)ethylenediamine was added, and the reaction was carried out at 170° C. for 6 hours. Utilize vacuum distillation to extract, the internal pressure during extraction is 2mmHg, extraction temperature is 210 ℃, extract 3 hours, remove the unreacted N-(1-naphthyl)ethylenediamine and its derivatives, Finally, a dispersed ethylene-propylene copolymer, that is, a dispersed viscosity index improver product a-3, was obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com