Low-surface tension hyperbranched shrinkage reduction type polycarboxylate superplasticizer and preparation method thereof

A low surface tension, polycarboxylate technology, applied in the field of construction admixtures, can solve the problems of small plastic shrinkage of high-strength concrete, insufficient reduction, increase early shrinkage and total shrinkage, etc., to achieve large steric hindrance and prevent shrinkage Effect of cracking and improving dispersion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

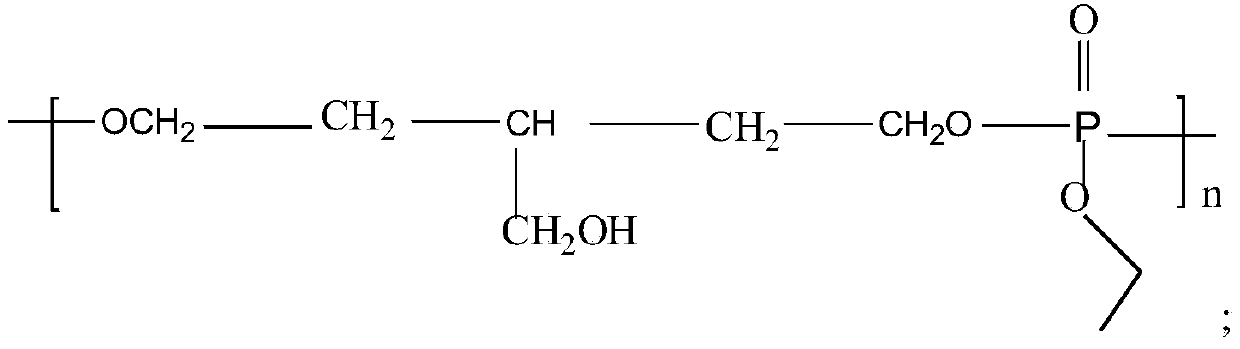

[0035] (1) Preparation of polyphosphate:

[0036] Under nitrogen protection, add 10mol trimethylolpropane to the first reaction device, cool in an ice-water bath for 1h, add 500ml triethylamine, and drop 100ml dichloromethane solution (solution The concentration is 100mol / L), and the dropping time is 1h. After the dropping is completed, the temperature is slowly raised to 45°C for 24h. After standing for 12h, it is filtered with suction, the filtrate is collected, and the solvent is distilled off to obtain polyphosphate.

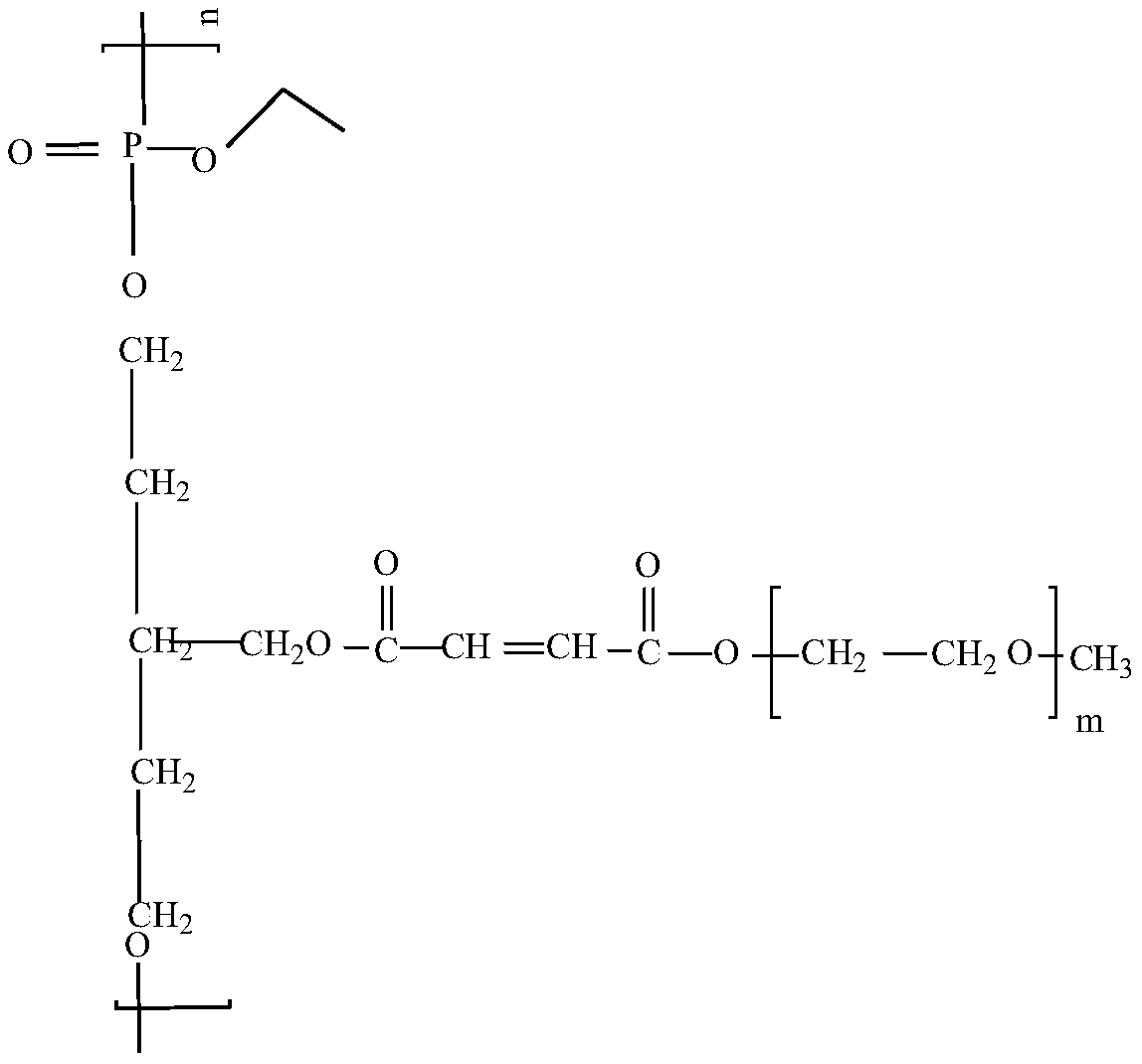

[0037] (2) Preparation of hyperbranched shrinkage-reducing functional monomer:

[0038] 100g molecular weight is the poly(ethylene glycol monomethyl ether) of 200, 49g maleic anhydride, the polyphosphate ester prepared by 240g step (1), 0.5g FeCl 3 ·6H 2 O and 0.6g of o-tert-butylphenol were added to the second reaction device, and under the protection of nitrogen, they were reacted at a constant temperature of 90° C. for 5 hours to obtain the hyperbranche...

Embodiment 2

[0045] (1) Preparation of polyphosphate:

[0046] Under nitrogen protection, add 10mol trimethylolpropane to the first reaction device, cool in an ice-water bath for 1h, add 500ml triethylamine, and drop 100ml dichloromethane solution (solution The concentration is 100mol / L), and the dropwise addition time is 1h. After the dropwise addition is completed, the temperature is raised slowly to 45°C for 24h. After standing for 12 hours, filter with suction, collect the filtrate, and distill off the solvent to obtain polyphosphate.

[0047] (2) Preparation of hyperbranched shrinkage-reducing functional monomer:

[0048] 100g molecular weight is the poly(ethylene glycol monomethyl ether) of 500, 19.6g maleic anhydride, the polyphosphate ester prepared by 95g step (1), 1g SnCl 2 2H 2 O and 0.8 g of phenothiazine were added to the second reaction device, and under the protection of nitrogen, they were reacted at a constant temperature of 100° C. for 6 hours to obtain the hyperbranch...

Embodiment 3

[0055] (1) Preparation of polyphosphate:

[0056] Under nitrogen protection, add 10mol trimethylolpropane to the first reaction device, cool in an ice-water bath for 1h, add 500ml triethylamine, and drop 100ml dichloromethane solution (solution The concentration is 100mol / L), and the dropwise addition time is 1h. After the dropwise addition is completed, the temperature is raised slowly to 45°C for 24h. After standing overnight, suction was filtered, the filtrate was collected, and the solvent was distilled off to obtain polyphosphate.

[0057] (2) Preparation of hyperbranched shrinkage-reducing functional monomer:

[0058] Polyethylene glycol monomethyl ether, 12.25g maleic anhydride, 60g step (1) prepared polyphosphate, 1.2g NaHSO with 100g molecular weight are 800 4 ·H 2 O and 1.0 g of phenothiazine were added to the second reaction device, and under the protection of nitrogen, they were reacted at a constant temperature of 80° C. for 4 hours to obtain the hyperbranched ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com