Deceleration clutch device and washing machine

A technology of clutch device and clutch flower, which is applied in the field of washing machines, can solve the problems of slow sliding down of the clutch shaft sleeve, blockage of the clutch sleeve, slow sliding speed, etc., and achieve faster separation and approach speed and faster up and down sliding Speed, frictional noise reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

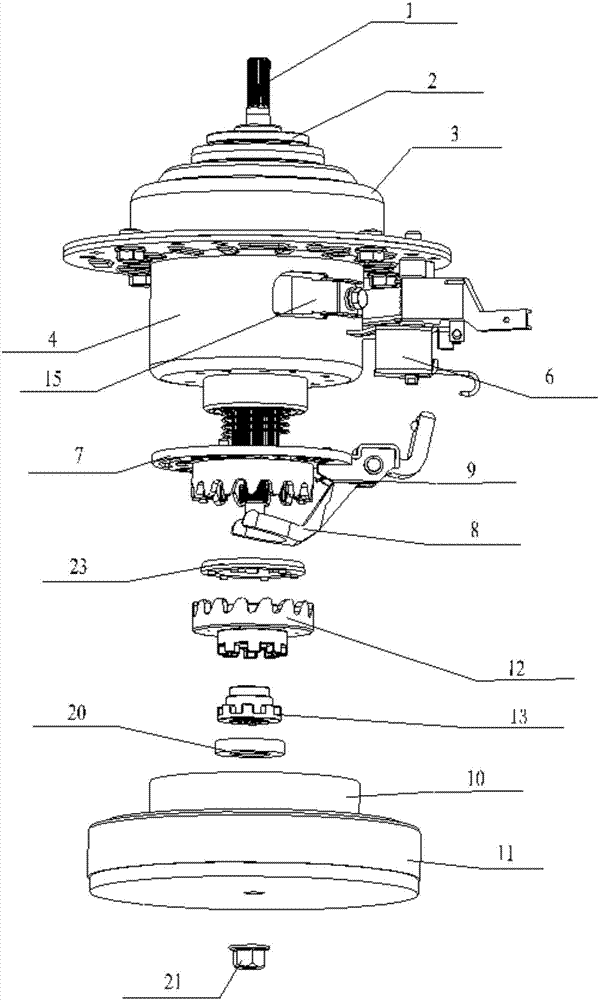

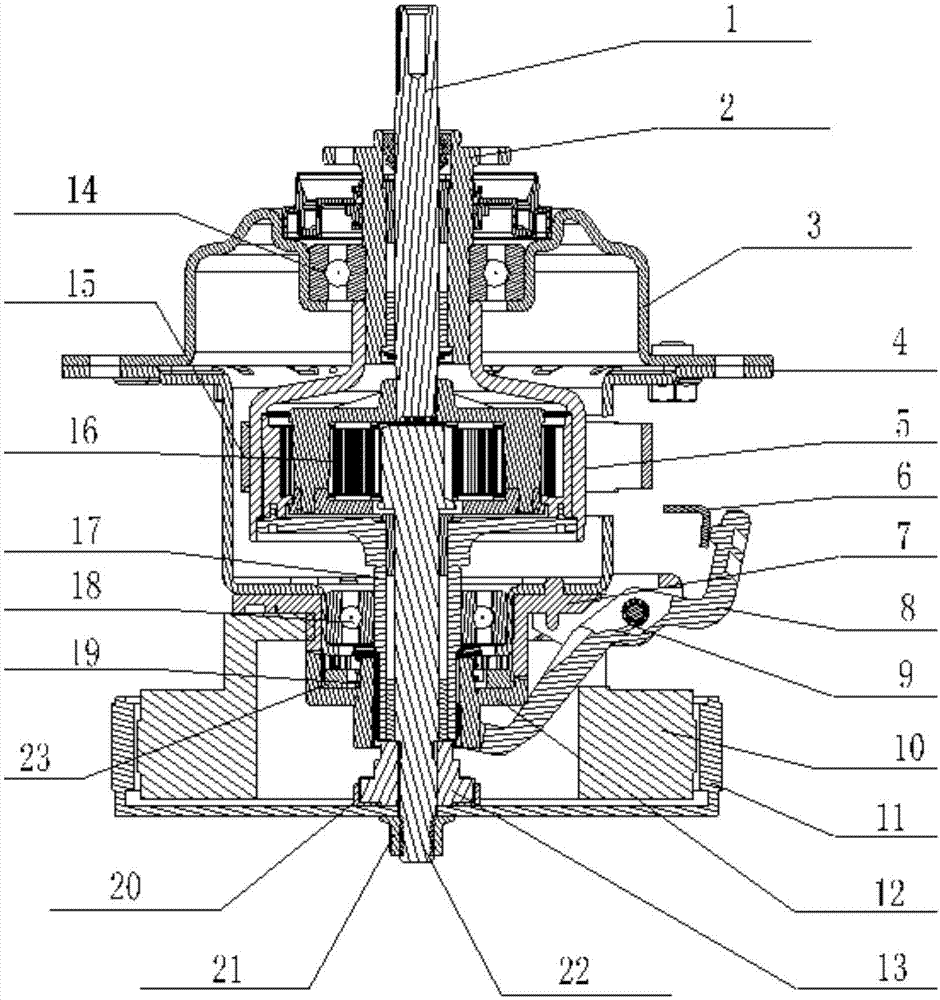

[0053] Such as Figure 1-26 As shown, in this embodiment, the input shaft 22 is sleeved with a torque bushing 13, the torque bushing 13 cannot rotate axially relative to the input shaft 22, and the torque bushing 13 and the clutch bushing 12 To realize the connection between the clutch bushing 12 and the rotor 11, the lower part of the torque bushing 13 is connected with the rotor 11. Preferably, a first damping pad 20 is provided between the lower part of the torque bushing 13 and the rotor 11 , to reduce the noise generated by the rotor 11 during rotation and the impact on the reduction clutch device.

[0054] The inner wall of the torque bushing 13 is provided with a second internal spline 36 to realize the meshing connection between the torque bushing 13 and the input shaft 22, so that the torque bushing 13 rotates with the rotation of the input shaft 22 and rotates The top of the torque shaft sleeve 13 is provided with a first external spline 38, and the bottom of the cl...

Embodiment 2

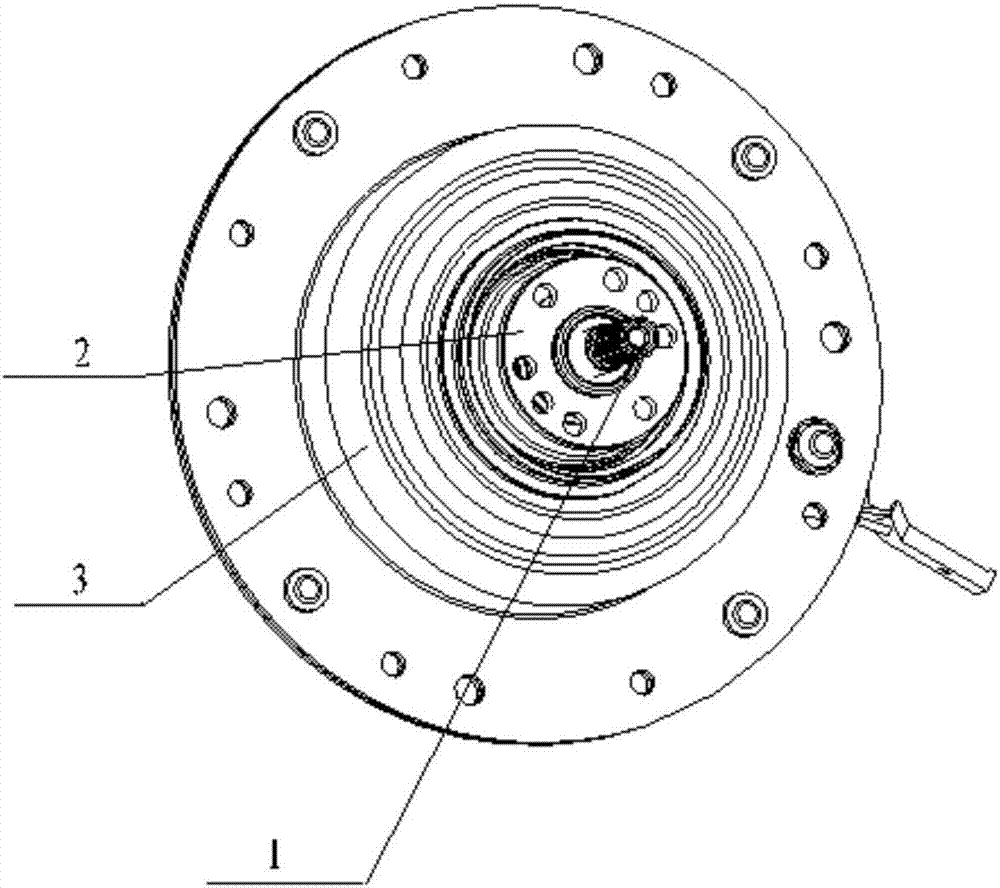

[0057] Such as Figure 1-26 As shown, in this embodiment, a housing 31 consisting of an upper end housing 3 and a lower end housing 4 is provided above the clutch shaft sleeve 12, a fixing bracket 7 is provided on the housing 31, and the outer periphery of the positioning protrusion 29 is provided with The positioning wall 30 extending upwards, after the clutch sleeve 12 slides upwards, the positioning wall 30 is connected with the fixed bracket 7, specifically, the lower part of the fixed bracket 7 is provided with a positioning spline 37, and the upper part of the positioning wall 30 is provided with a corresponding The second clutch spline 32, to realize the engagement connection of the two, in the washing machine, to prevent the washing tub from rotating during washing. Wherein, the tooth profile end of the positioning spline 37 is designed as a small circular arc, the angle between the left side of the tooth profile and the vertical plane is 0°-10°, and the angle between ...

Embodiment 3

[0063] Such as Figure 1-26 As shown, in this embodiment, the oil inlet end of the oil leakage hole 26 is set outside the oil storage tank 25 and is set close to the outside of the positioning protrusion 29 .

[0064] The above arrangement prevents the lubricating grease in the oil storage tank 25 from being thrown out of the oil storage tank 25 when the clutch sleeve 12 rotates.

[0065] The specification of the oil leakage hole 26 is smaller than that of the oil storage tank 25 , so that the lubricating grease slowly flows to the contact surface between the positioning protrusion 29 and the shift fork 8 .

[0066] A plurality of oil storage tanks 25 are evenly distributed on the positioning protrusion 29;

[0067] Preferably, the oil leakage hole 26 is a through hole with a circular cross section.

[0068] The second damping pad 23 is sandwiched between the positioning protrusion 29 and the housing 31 to reduce the contact noise between the positioning wall 30 and the hous...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com